In today's environment of stricter environmental compliance requirements, the need for more refined industrial processes, and surging demand for safety protection, gas monitoring is no longer an ‘optional extra’ but a ‘must-have’ for production safety, environmental compliance, and scientific research accuracy. However, traditional gas analysers either only support single-component detection with low efficiency, lack the precision required to meet stringent standards, or are helpless in complex operating conditions (such as high humidity or multiple gas cross-interference) These pain points are being addressed one by one by the EDK 9500 series Fourier Transform Infrared Gas Analysers.

Who is calling for more efficient gas monitoring solutions?

The EDK 9500 series Fourier Transform Infrared Gas Analyser precisely addresses the core needs of multiple industries, serving as a ‘reliable assistant’ for the following groups:

Environmental monitoring and enforcement agencies: These agencies require continuous monitoring (CEMS) of pollutants such as CO, NO₂, and SO₂ emitted by industrial facilities to ensure data compliance and traceability. The EDK 9500's ±2% FS accuracy and detection limits as low as the ppb level perfectly meet environmental standards.

Chemical and petroleum companies: Real-time monitoring of toxic and harmful gases such as ethylene oxide, HCl, and toluene is required during production processes to ensure worker safety and precisely control reaction progress. The EDK 9500's ability to ‘measure hundreds of gases at once + automatically compensate for cross-interference’ makes process monitoring more efficient.

Laboratories and research institutions: When studying agricultural and forestry ecology, space environments, or special chemical reactions, it is often necessary to detect trace gases such as NH₃ and N₂O. The EDK 9500's high-resolution spectral technology and library of over 300 measurable gases provide reliable data support for research.

Emergency and safety teams: In the event of sudden leaks (such as highly toxic gases like HCN or HF), the portable version's rapid response and robust shock-resistant design enable detection personnel to immediately assess gas concentrations and mitigate risks.

Food Processing and Energy Industries: Monitoring CO₂ concentrations is essential for food preservation, while hydrogen fuel cell production requires purity testing. The EDK 9500's multi-range automatic switching function (from 10 ppb to 100%) effortlessly handles monitoring needs spanning ultra-low to ultra-high concentrations.

Why is the EDK 9500 series Fourier infrared gas analyser the ‘preferred choice’?

As the crystallization of Duke’s new generation of Fourier infrared technology, its advantages stem from the perfect fusion of cutting-edge technology and user-friendly design:

Core Advantages: Accurate, Efficient, Flexible

300+ Gases Covered: Based on Fourier Transform Infrared (FTIR) principles, a single scan can measure the concentrations of over 100 gases without the need to change hardware. Adding new gases only requires the addition of calibration files via software, completely eliminating the cumbersome process of ‘one instrument for one gas.’

PPB-Level Accuracy, Compliance Assured: A 5-metre optical path sample cell paired with a 4TE-MCT detector achieves a CO₂ detection limit as low as 0.02 ppm and ethylene oxide as low as 0.02 ppm. Even trace gases as low as 10 ppb can be precisely detected, meeting the most stringent monitoring standards.

Reliable performance in complex conditions: The instrument features a rhodium-coated filter resistant to chemical corrosion and an inert aluminum-coated sample cell, enabling stable operation in environments with 20% absolute humidity. It maintains high accuracy even in high-humidity or corrosive gas environments, addressing the traditional challenges of water vapour and corrosion.

Maintenance-free design for peace of mind: A permanently aligned optical system and vacuum-sealed infrared light source reduce daily maintenance costs. Built-in active suppression technology for H₂O and CO₂ background noise eliminates the need for frequent calibration, reducing labour costs.

User-friendly features: Simple operation and strong adaptability

Range ‘customized to your needs’: Covers concentrations from 10 ppb to 100%, accurately adapting to both ultra-low concentration environmental air monitoring and high concentration process gas analysis.

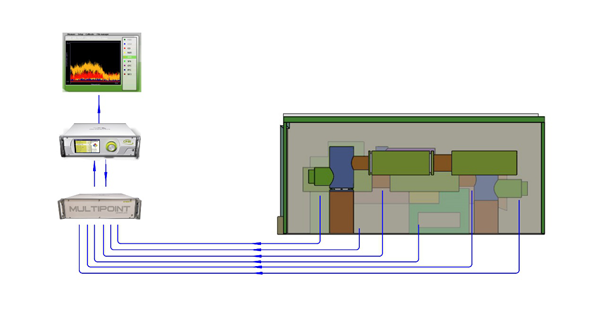

‘Foolproof’ operation experience: The 10-inch touchscreen interface intuitively displays health status and alarm information, allowing even those without professional background to quickly get started; Independent test logs automatically store data, and with Profinet/Profibus protocols, it seamlessly integrates with enterprise management systems.

‘Lightweight and versatile’ for multiple scenarios: Fixed units are ideal for online monitoring, while portable units feature an innovative anti-vibration design, lightweight and easy to carry, meeting the needs of field, workshop, and emergency mobile testing.

From continuous emission monitoring to chemical process control, from laboratory research to emergency response, the EDK 9500 series Fourier Transform Infrared Gas Analyzer redefines gas monitoring efficiency with its core capabilities of ‘versatility, speed, accuracy, and stability.’ Choose the EDK 9500 and make every gas monitoring task a ‘reliable choice.’

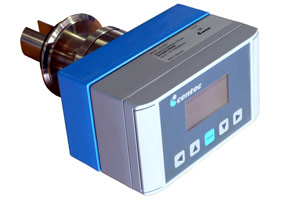

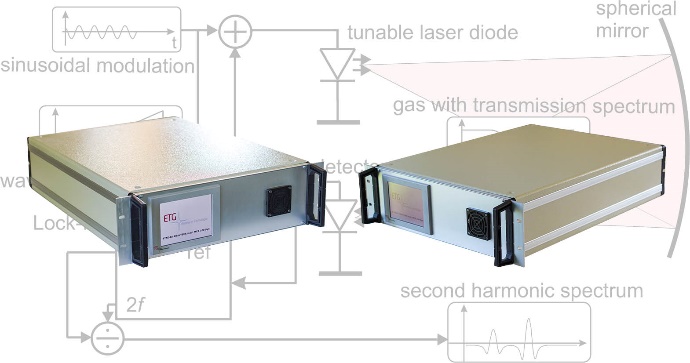

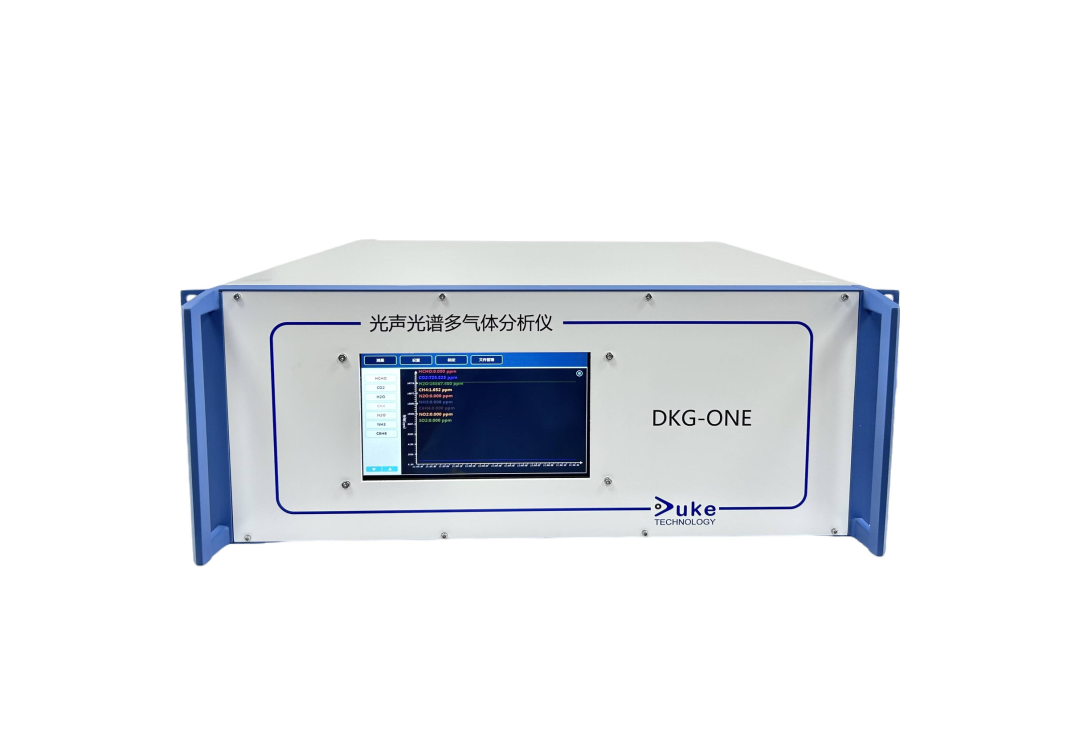

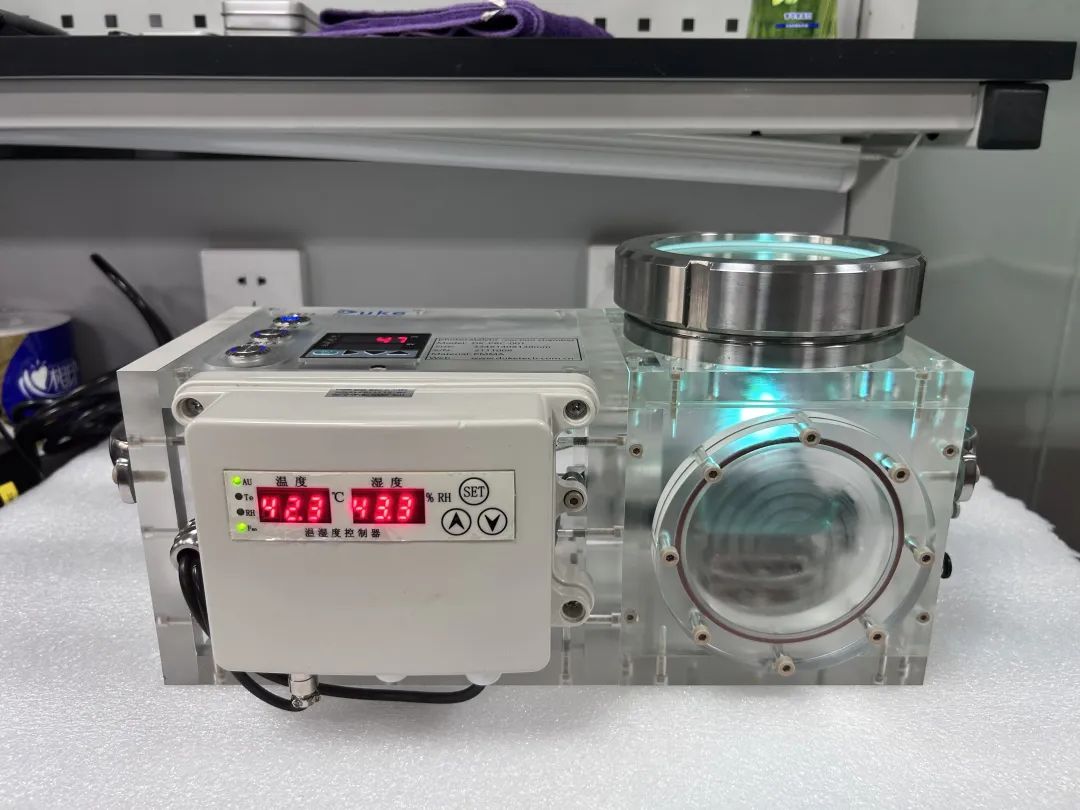

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system.

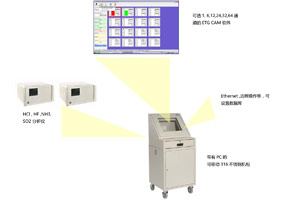

Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system. DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs

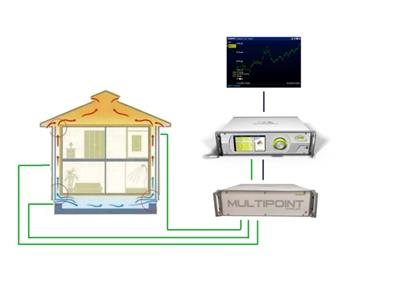

DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency.

Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency. SF6 is widely used in GIS as a good insulation and interruption gas.

SF6 is widely used in GIS as a good insulation and interruption gas.

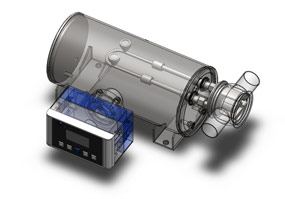

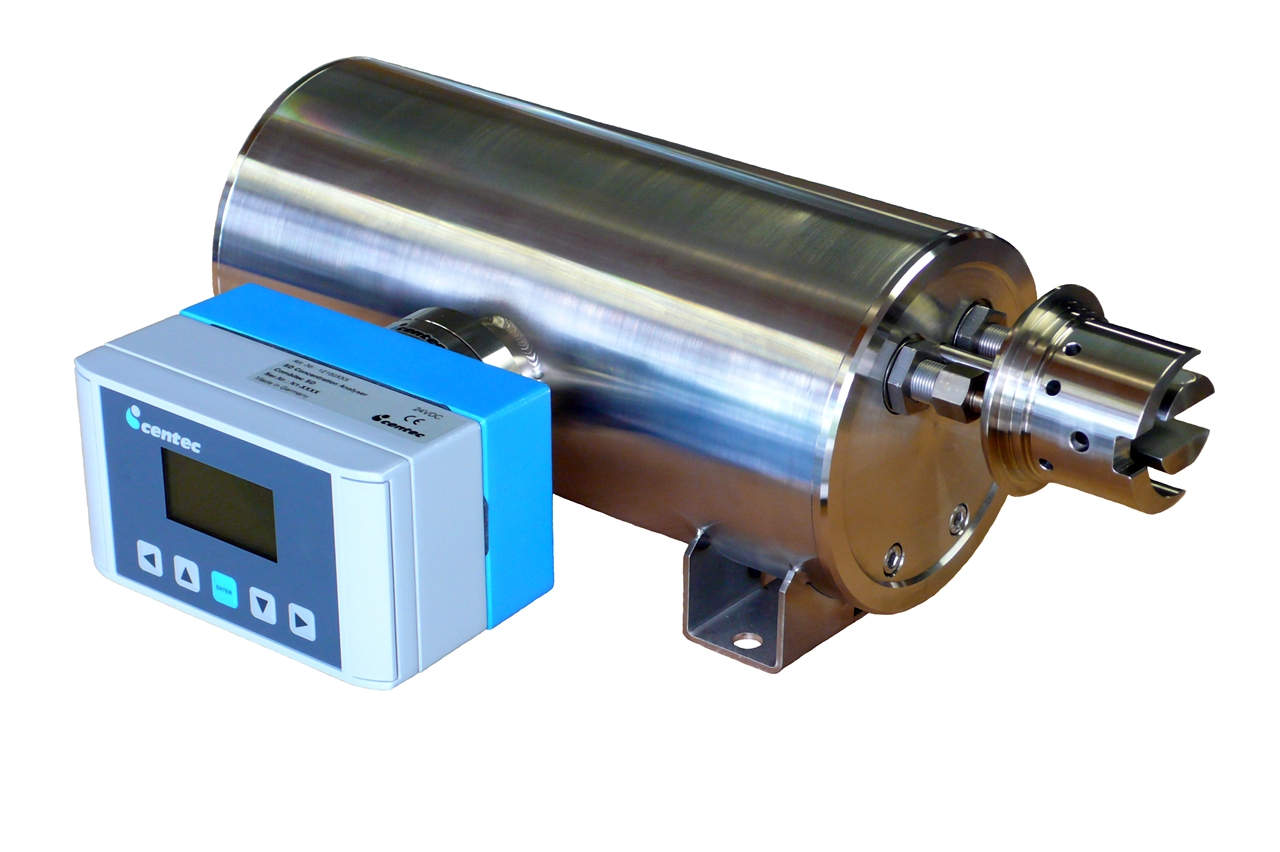

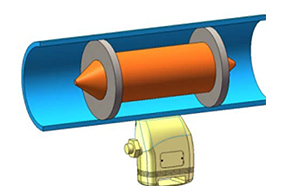

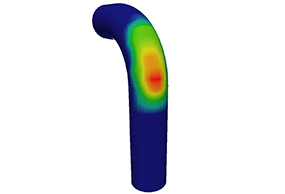

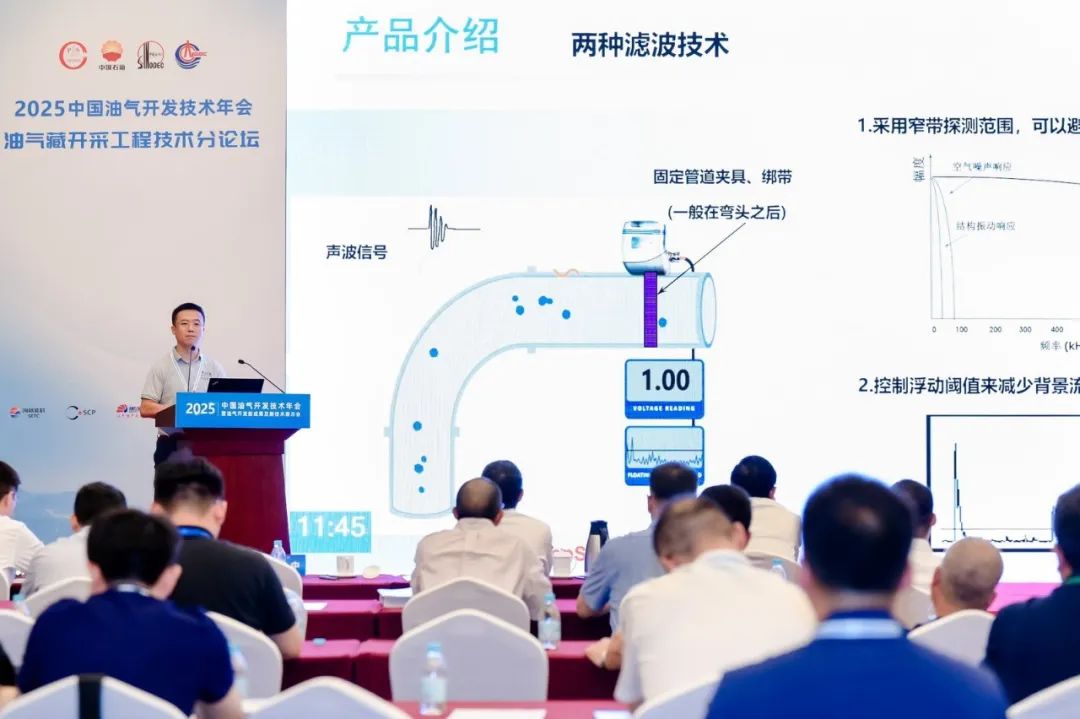

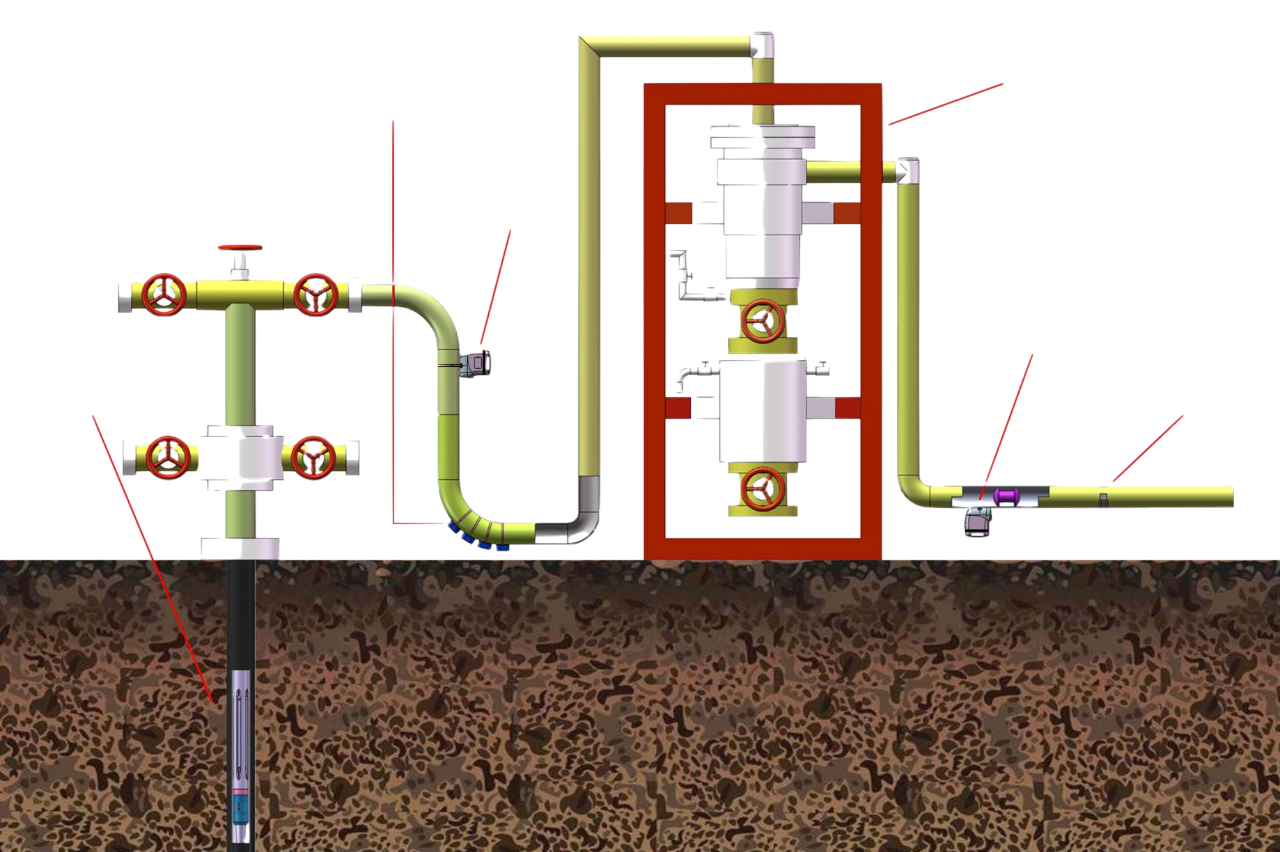

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p

When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP).

The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP). The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion.

The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion. Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials.

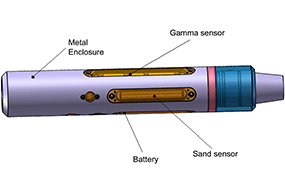

Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials. The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc

The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring The Duke photoacoustic spectroscopy greenhouse gas analyzer

The Duke photoacoustic spectroscopy greenhouse gas analyzer

An All-Round Tool for Catalytic Research

An All-Round Tool for Catalytic Research Infrared Photoacoustic Spectroscopy Gas Analyser

Infrared Photoacoustic Spectroscopy Gas Analyser