DK-SA 810 Compact Sand Monitoring System

Overview

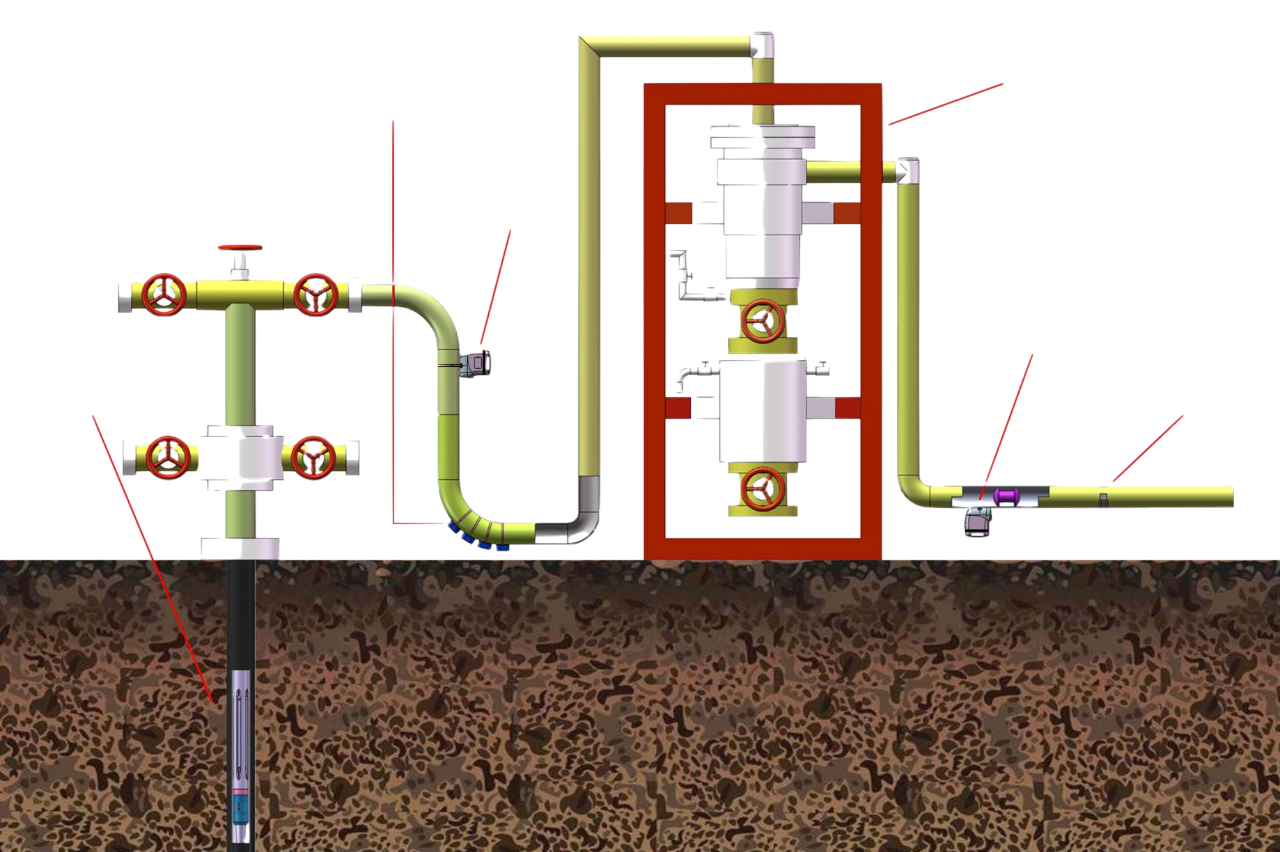

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring system developed by Duke measures he flow rates, instantaneous flow, and cumulative flow of solid particles during crude oil extraction, natural gas extraction, gas storage injection and production, drilling, logging, fracturing, well completion, workover, and cementing processes.

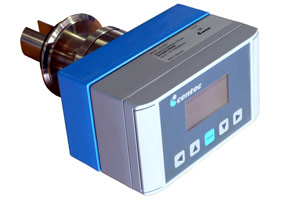

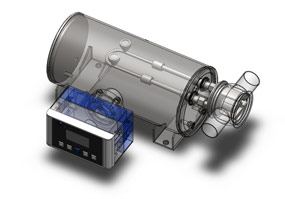

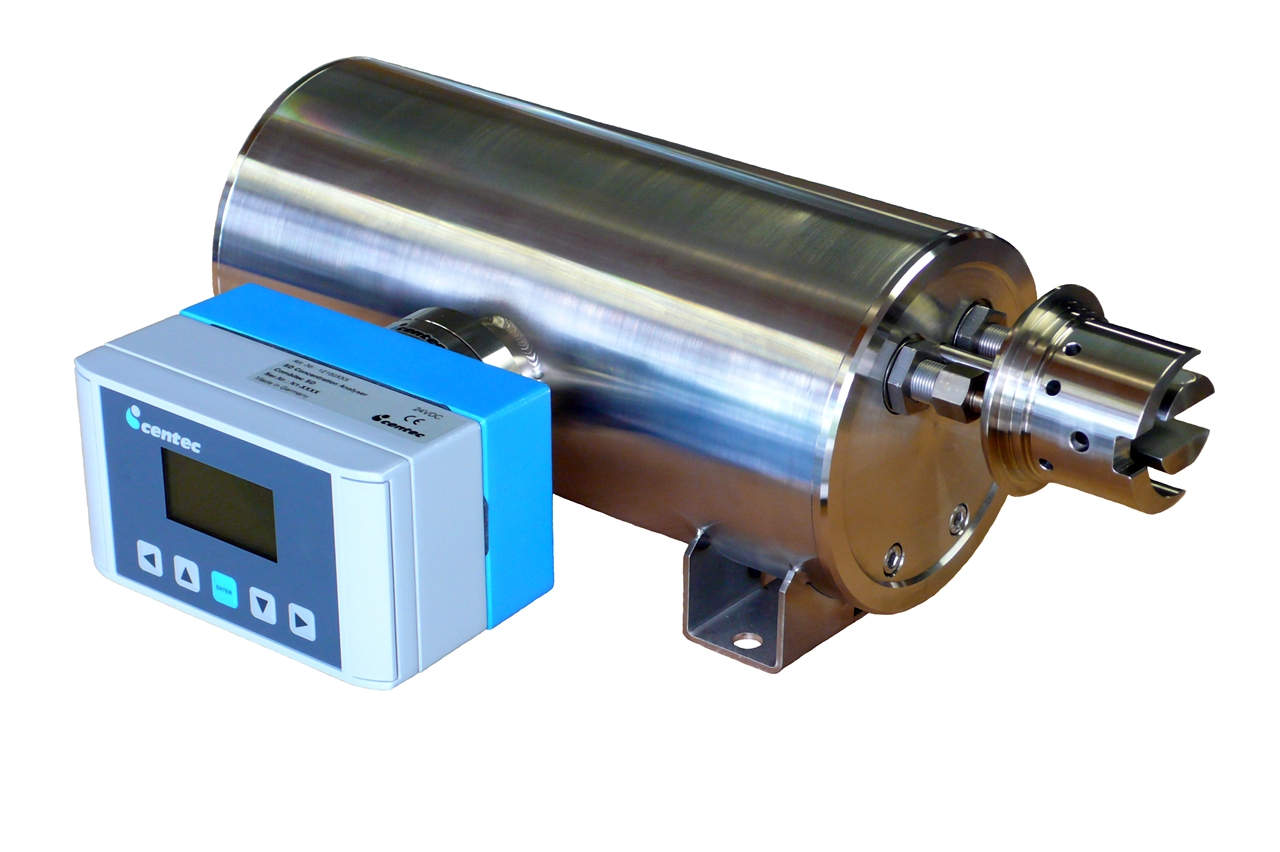

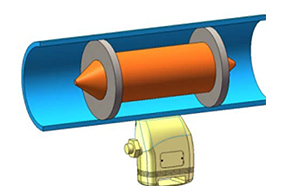

The sand and gravel monitoring instrument consists of two parts: a compact and robust clamp-on acoustic sensor and a sand and gravel transmitter. It can be applied in any oil & gas field where efficient extraction is needed, allowing for real-time, accurate, and quantitative measurements of sand and gravel flow.

In recent years, there has been a market demand for real-time measurement of particle capacity and flow rates. The unique sensor is installed at appropriate pipeline connections or bends, where the turbulent profile is most representative of fluid characteristics. The sensor directly integrates measurements of solid particle content and flow, eliminating the need for additional flow rate measurements.

The sensor is intrinsically safe, with ATEX EExia IIB/C certification.

Features:

l Optimizes Production Efficiency

l Suitable for Multiphase Fluids

l Qualitative and Quantitative Measurement

l Pipeline & Valve Hazard Assessment

l Non-Contact, Easy to Install, Easy to Calibrate

l Facilitates Most Efficient Control Methods

l Measures Sand Flow in Oil and Gas Wells

On-site Applications

In oil or gas extraction wells, solid particles/sand gradually increase with the extraction process. As the well ages, solid particles/sand adhering to the inner walls of the well or pipeline will accumulate year by year, potentially leading to blockages. It is essential not only to prevent the increase of solid particles/sand but also to optimize the production process, which presents a significant technical challenge. If not managed properly, these particles/sand can cause damage to pipelines or valves. Therefore, it is crucial to monitor the flow rate, instantaneous flow, cumulative flow, and movement patterns of sand in the pipeline in real time. When solid particles or sand continuously accumulate during production, it is necessary to assess the risks associated with these particles. Hence, real-time monitoring of the operational status of solid particles/sand in the pipeline is essential.

When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid particles is crucial.

The foundation for measuring solid particles/sand monitoring requires real-time detecting and predicting of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand.

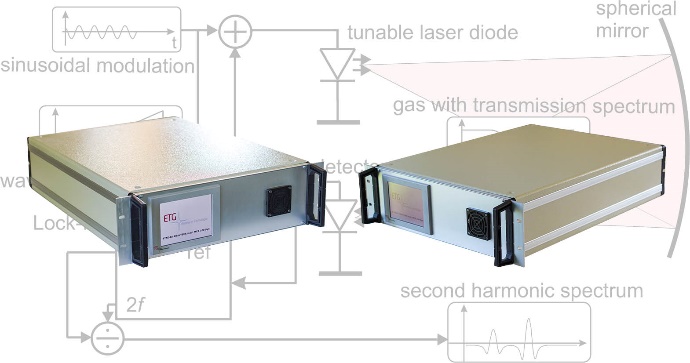

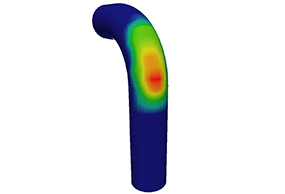

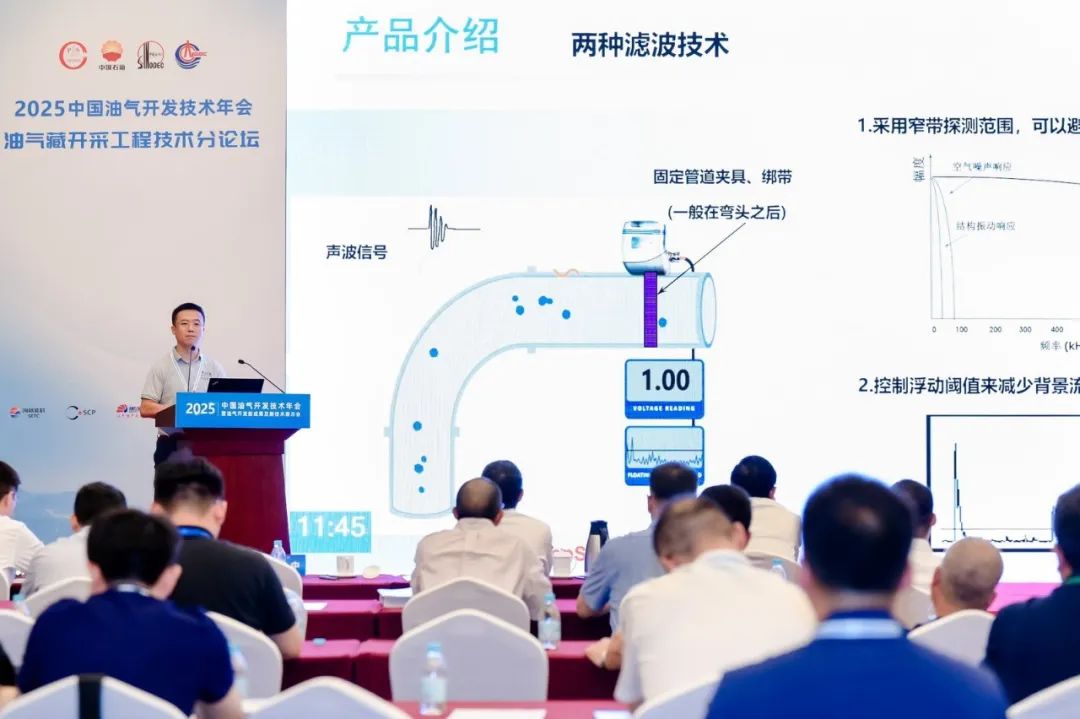

Using the sonar principle based on passive acoustic sensing, the movement patterns of sand and solid particles can be measured, allowing for the determination of flow rate, instantaneous flow, and cumulative flow of sand in natural gas, crude oil, drilling fluid, and fracturing fluid. When sensors are installed at pipeline bends, they monitor the acoustic signals generated by solid particles colliding with the inner walls of the pipeline, and analyze the flow of sand in real time.

Acoustic Sensor

The unique acoustic sensor is an intrinsically safe unit(ATEX EEx ia IIC T4), made from 316 stainless steel, with a protection rating of up to IP68. The acoustic sensor can be widely used in various on-site conditions. Installation is very simple; the sensor can be bundled to the outer wall of the pipe with a stainless steel strap, or connected to the elbow using a stainless steel adapter. his allows it to receive acoustic waves generated by solid particles colliding with the pipe wall. Since the sensor only receives signals from a very narrow bandwidth, it effectively filters out noises generated by gases or liquids. Changes in the frequency and amplitude of the acoustic signals can reveal the flow rate, instantaneous flow, cumulative flow, and movement patterns of sand in the pipe.

Integrated Measurement of Flow Rate, Flow, and Flow Patterns

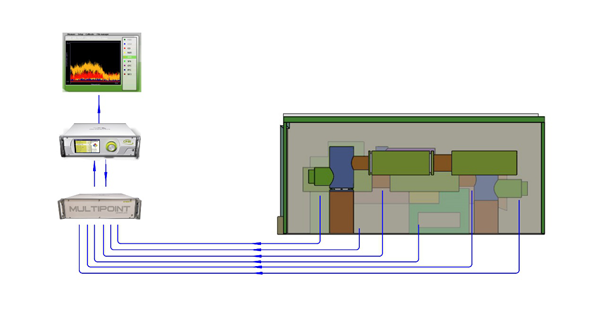

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. All data is transmitted through the compact main unit of the sand monitoring system (which includes a Zener barrier and RS485(Modbus) data and communication module), allowing for data transmission over distances of up to 1500 meters. It can connect to the customer’s data acquisition systems, such as DCS, PLC, and SCADA systems, to monitor the flow rate, instantaneous flow, and cumulative flow of sand in crude oil & gas pipes. The data can also be stored in the main control unit or imported and downloaded to a PC for analysis via cable connections.

Technical Parameters - Sensor |

Principle: | Intelligent Acoustic Sensor | Impact Rate: | 0~100000SIR |

Sand Rate: | >0.1g/s, Up to 10000g/s | Resolution: | Minimum 0.001g/s |

Accuracy: | ±5%(Air>0.5m/s,Liquid>1m/s) | Repeatability: | Better than 1% |

Minimum Sand Size: Oil/Water: 25μm; Air/Gas: 15μm; Fluid viscosity less than 3000mPa.s |

Power: | 24VDC@5W | Outer Diameter: | >25mm |

Installation: | Non-intrusive Bundled | Fluid: | Multi-Phases/Gas |

Tamperature: | Surface -40~+200℃ | Cable: | 4Pin,with outer shell |

Explosion Proof Certification: cATEX EEx ia IIC T6, EEx ia IIC T4 or EEx ia IIB T4 |

Protection: | IP66, IP68 | Enclosure: | Aero Aluminum or 316 Stainless Steel |

Weight: | Aluminum<1.5Kg,Stainless Steel<2.7Kg | Size: | H70 mm x D65 mm x L118 mm |

DK-SA 810C Controller - Compact |

Power: | 110/240V AC@50/60Hz 24VDC 10W | Software: | Linux software, embedded |

Output: | RS485 (Modbus), 4–20mA Analog Signal, Optional RS232, 2 Alarm Relay Outputs. |

Protection: | IP56、IP66、IP68(optional) | Comm. distance: | 1500 meters |

Weight: | 3.17Kg | Size: | 200 x154 x120mm |

Enclosure: | 316L Stainless Steel | EPC: | Exd IIB T4 EEx ia IIC T6, EEx ia IIC T4 |

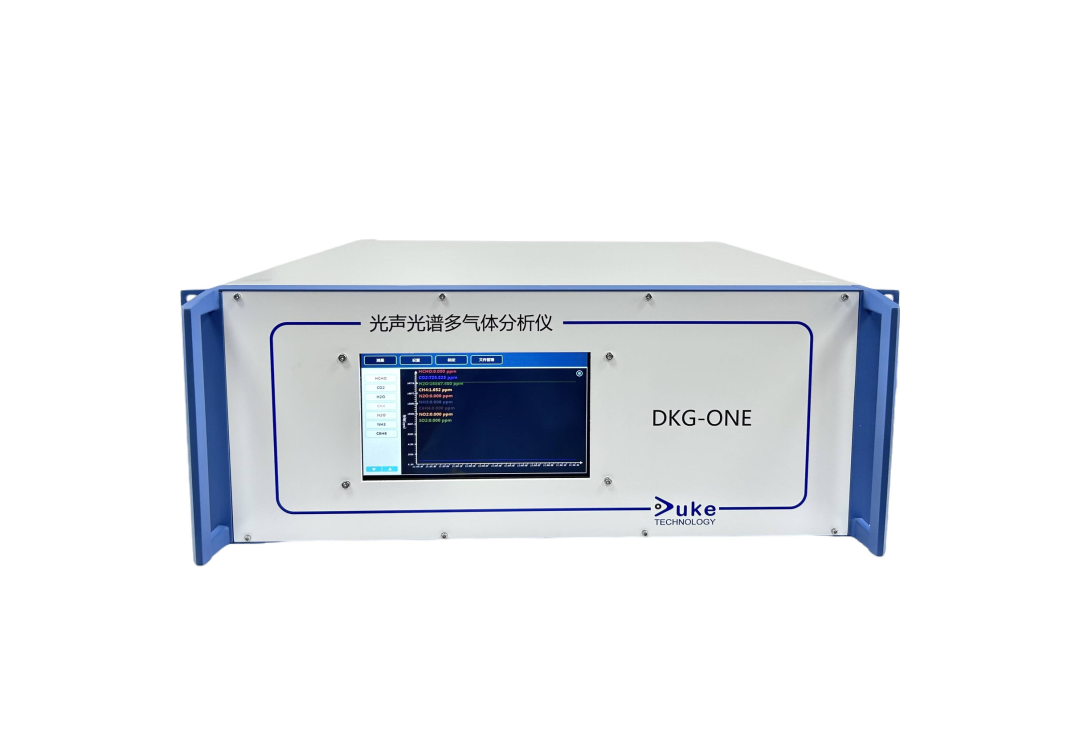

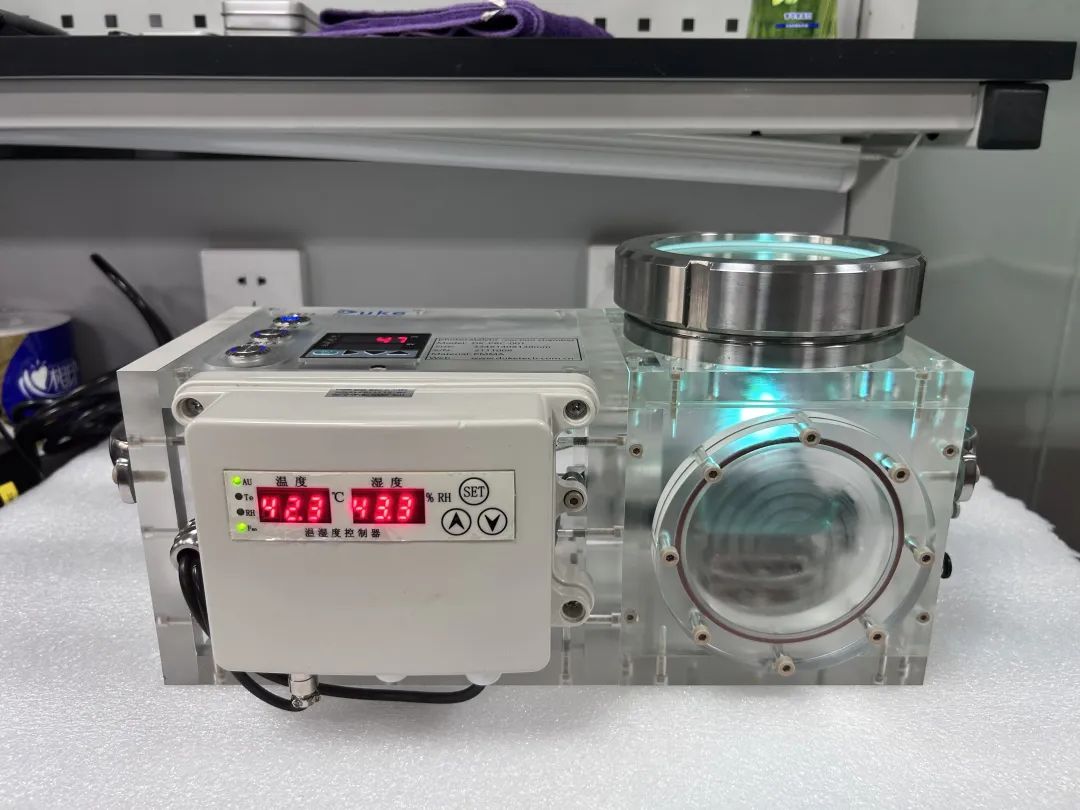

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system.

Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system. DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs

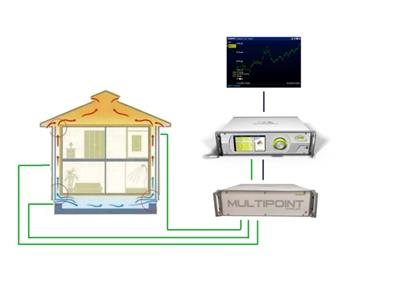

DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency.

Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency. SF6 is widely used in GIS as a good insulation and interruption gas.

SF6 is widely used in GIS as a good insulation and interruption gas.

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p

When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP).

The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP). The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion.

The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion. Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials.

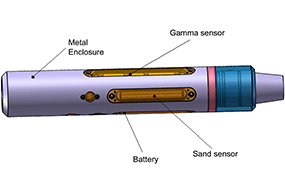

Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials. The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc

The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring The Duke photoacoustic spectroscopy greenhouse gas analyzer

The Duke photoacoustic spectroscopy greenhouse gas analyzer

An All-Round Tool for Catalytic Research

An All-Round Tool for Catalytic Research Infrared Photoacoustic Spectroscopy Gas Analyser

Infrared Photoacoustic Spectroscopy Gas Analyser