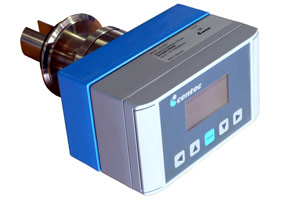

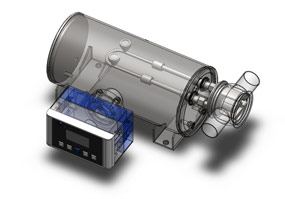

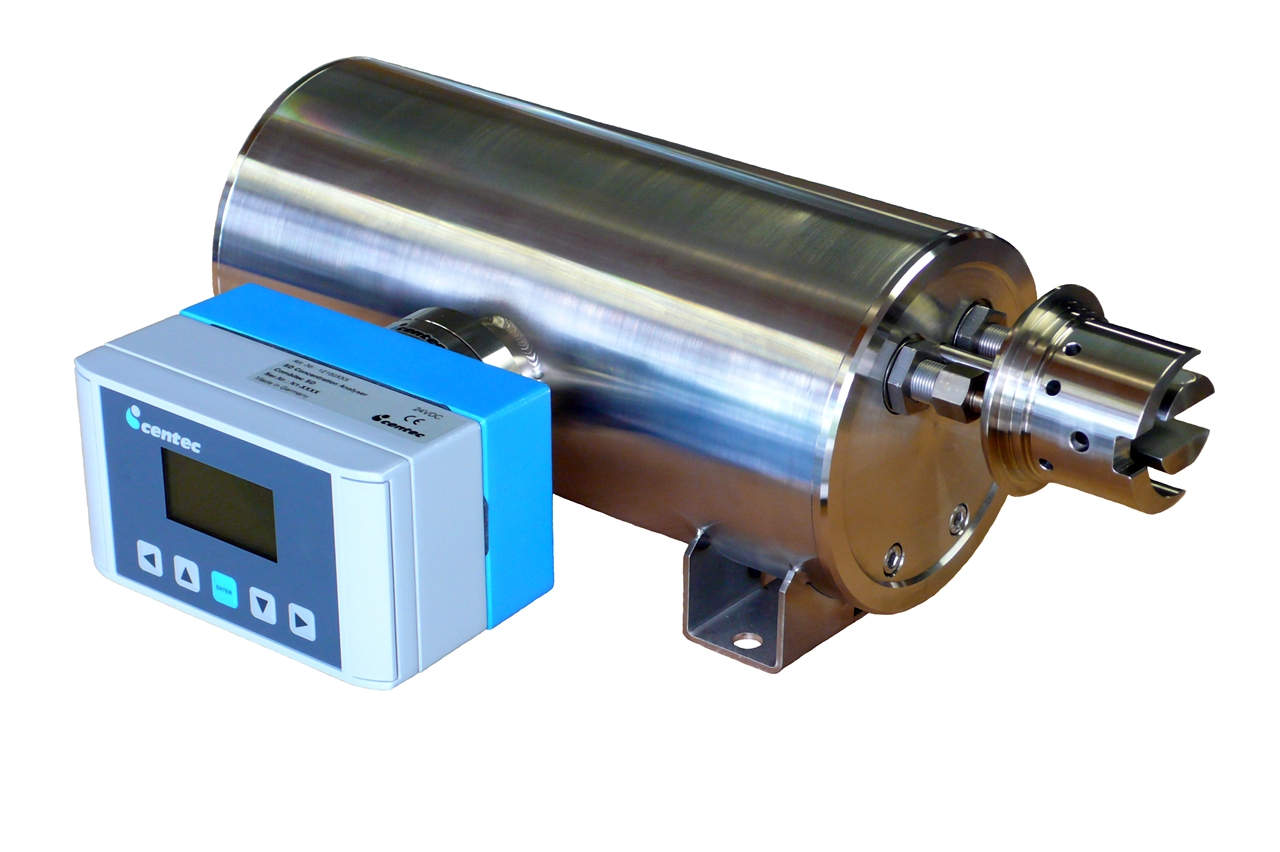

TDLS Laser microgas analyzer

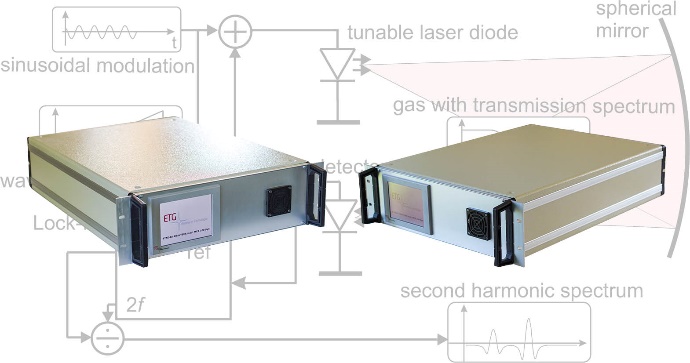

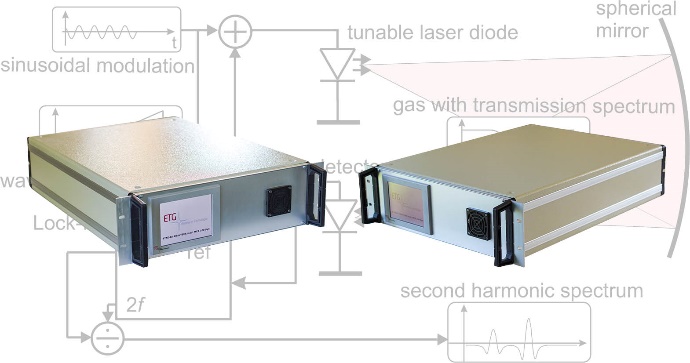

Principle

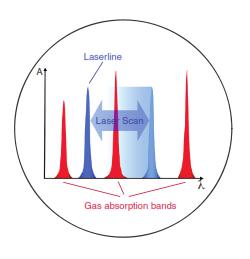

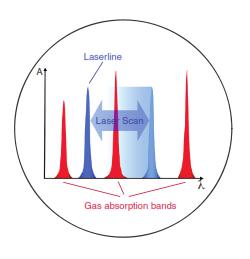

EDK series products adopt enhanced TDLS technology with a scanning wavelength of 0,1nm to avoid cross-interference of the absorption wavelength of the target gas,Also known as the "fingerprint spectrum," it enables high-resolution near-infrared absorption measurements. Electronic phase-locking technology can extract and separate the absorption information of the measured gas from the photoelectric information. This detection method does not need a physical reference pool and provides continuous sensor state monitoring. EDK TDL6900 series products provide high precision and low detection limit solutions. The instrument has the characteristics of non-contact measurement, free calibration, low cost and easy operation with high accuracy and selectivity for the gas under test.

EDK TDL6900 series products can easily measure some trace gases that are not easy to measure by conventional methods, such as NH3, CH4, CO2, H2O, etc Monitoring and analysis of these gases are critical in many industrial applications. High sensitivity and wide dynamic range are essential features of tunable semiconductor laser spectroscopy (TDLS) technology for the measurement of sub-ppm to % of gases

Typical application | Series products |

CH4 methane landfill | EDK 6901 A – Atmospheric trace CH4 monitoring |

Biogas analysis and monitoring | EDK 6902 A - Atmospheric trace CO2 monitoring |

Continuous monitoring of pollutant emissions | EDK 6903 A - Atmospheric trace NH3 monitoring |

Escape emissions | EDK 6903 H - Trace NH3 monitoring in high temperature and humidity |

Nature gas monitoring and analysis | EDK 6904 H- Trace HCl monitoring in high temperature and humidity |

Agriculture field | EDK 6900 X - CH4/NH3、 CO2 (NDIR)、O2 (ECD) |

Industrial process control |

|

The flue gas denitration SCR/DeNOx |

|

Climate change research |

|

Environmental research |

|

Breathing analysis |

|

Advantages

Ultra high sensitivity

Functional safety, continuous status report

Long life (+10 years)

Quick response

Low power consumption

Low-cost solution (no consumables, spare parts, no need to calibrate)

Excellent low-cost components determine low-cost sensors

19 "mounting bracket

Friendly UI

Data storage and logging

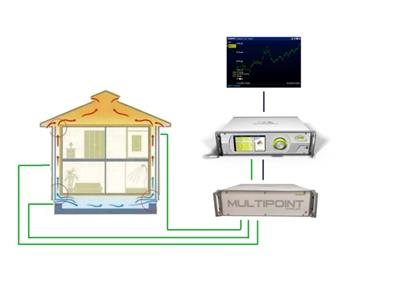

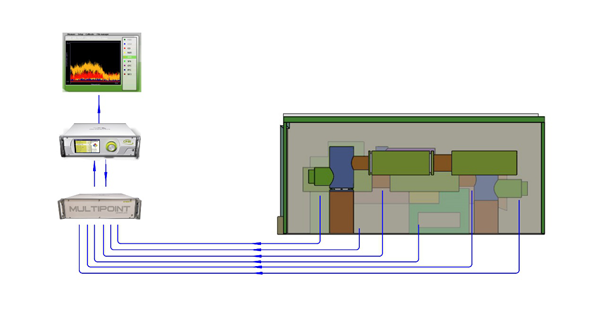

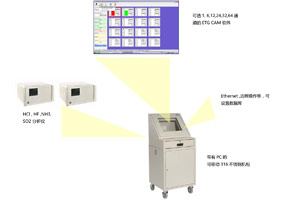

Scalable multipoint sampling system

Zero & wide range calibration

Sensor status self-test

specification

gas | Limited detection | Typical range |

NH3, (H2O)ammonia*** |

condition with high temperature and high humidity | 0.8 ppm | 0 – 20, 50, 100, (500) ppm |

HCl, (H2O) Hydrogen chloride *** |

condition with high temperature and high humidity | 0.8 ppm | 0 – 50, 100, (500) ppm |

NH3 ammonia | 0.4 ppm | 0 – 100 (500) ppm |

CH4 methane | 0.4 ppm | 0 – 100 (40'000) ppm |

CO2 carbon dioxide | 4.0 ppm | 0 – 1000 (300’000) ppm |

* other gases customizable |

Limited detection is under the condition of constant temperature pressure humidity (20°C, 1013 hPa、50 ± 1.5 % r.H.) A sudden change in system temperature causes a faster change in the detection limit than a change in concentration. Based on the spectrum, detection limit, as the high temperature increases and decreases, such as NH3 @ 190 ° C. |

Accuracy | ± 2%FS according to integral stability (temperature & pressure) |

precision | According to gases |

Zero drift | More than two hours per cycle -- within accuracy |

Span drift | More than eight hours per cycle -- within accuracy |

Maximum temperature error | < 0.1 reading/°C |

Linearity/repeatability | < ± 2% |

Cross interference | According to gas matrix or actual condition |

Resolution | 0.1 ppm |

Refresh rate | 1s (settable maximum120 s) |

T90 time | 2s (@flow rate3 L/min) |

Ambient temperature compensation | -10 ~65°C (The smallest possible temperature fluctuation) |

Maximum sample gas humidity | % absolute humidity, according to the operation condition, need to input calibration, through expansion compensation pressure, temperature or mixed gas concentration, customizable |

Maximum sample volume | 5(1)L/ min; 3L/min in calibration |

Power supply | VAC220-230/115 50/60 Hz |

Shell | 19’’ Standard rack installation (depth: 500mm) |

Explosion-proof grade | ExdII CT4, ExdII CT5,(customizable) |

Gas connection | Swagelok Φ6 mm |

Measuring method | In situ extraction |

Sampling pump | Internal |

Analog output | 4-20 mA Current loop (no isolation) |

port | Ethernet |

Display | 5.7” touch screen |

Data storage | Via USB port |

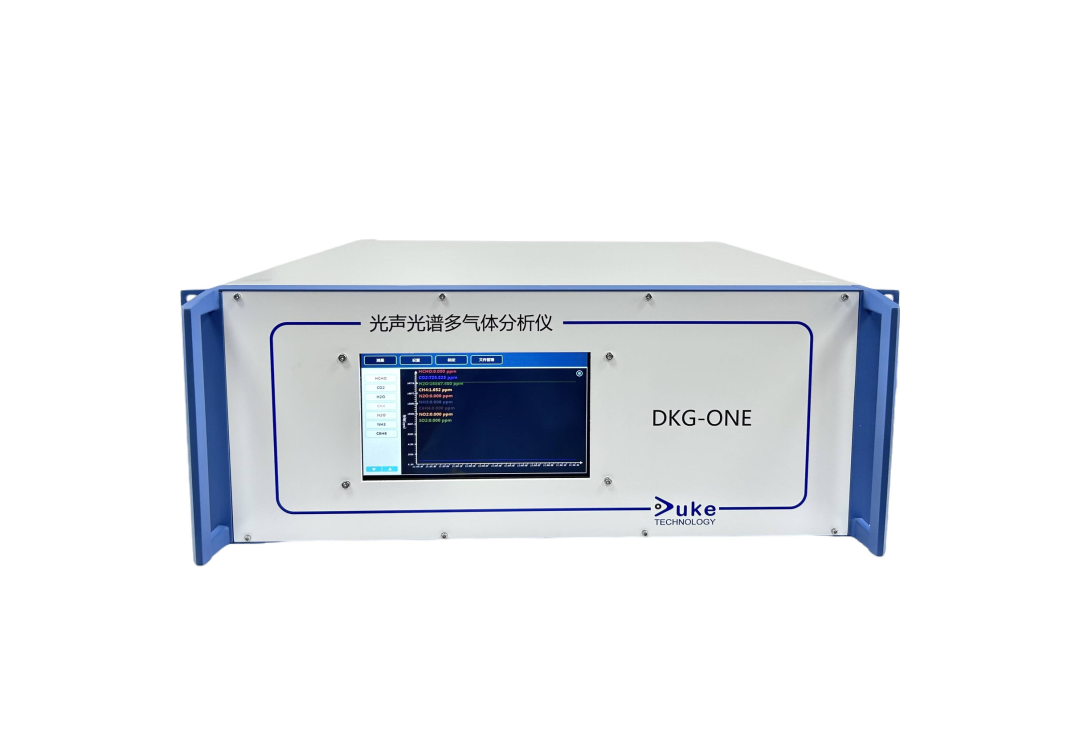

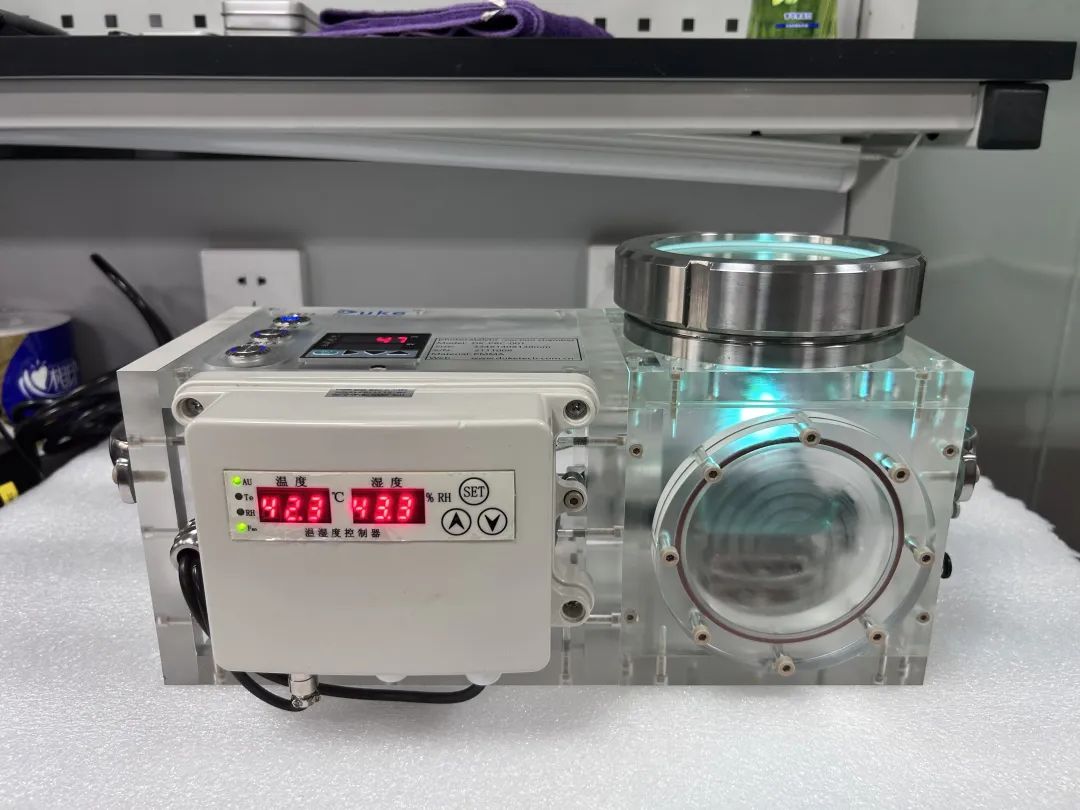

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system.

Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system. DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs

DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency.

Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency. SF6 is widely used in GIS as a good insulation and interruption gas.

SF6 is widely used in GIS as a good insulation and interruption gas.

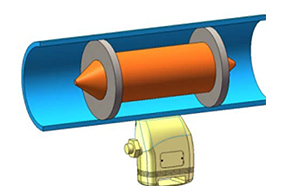

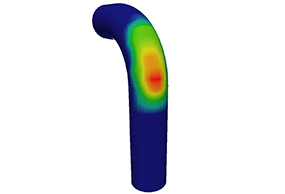

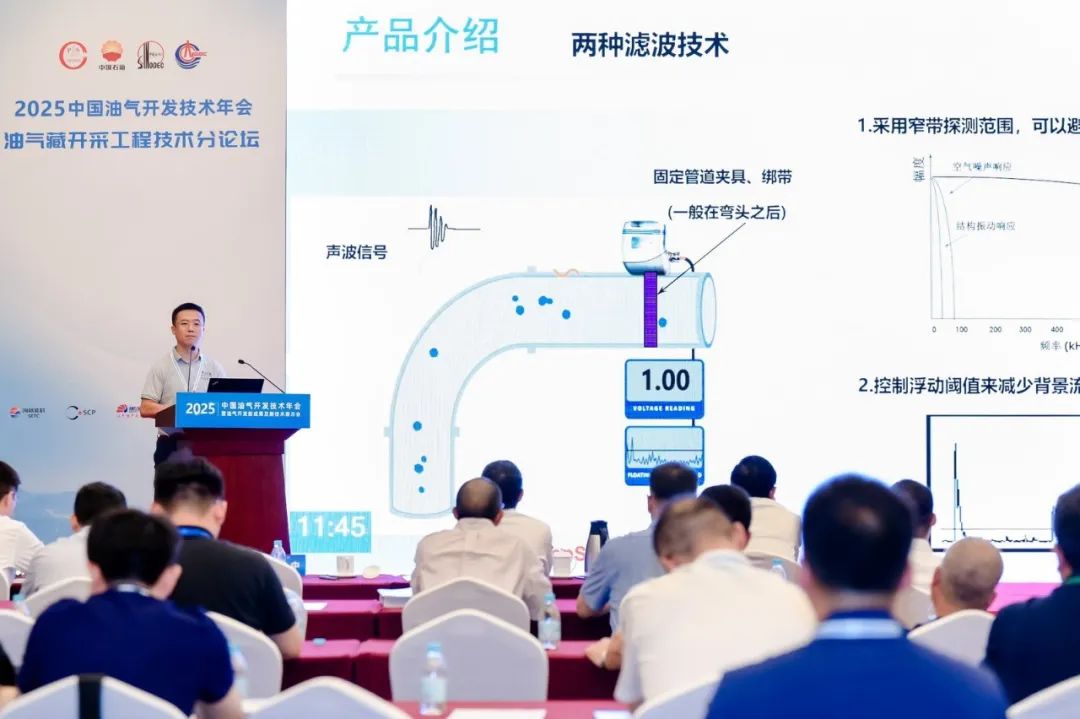

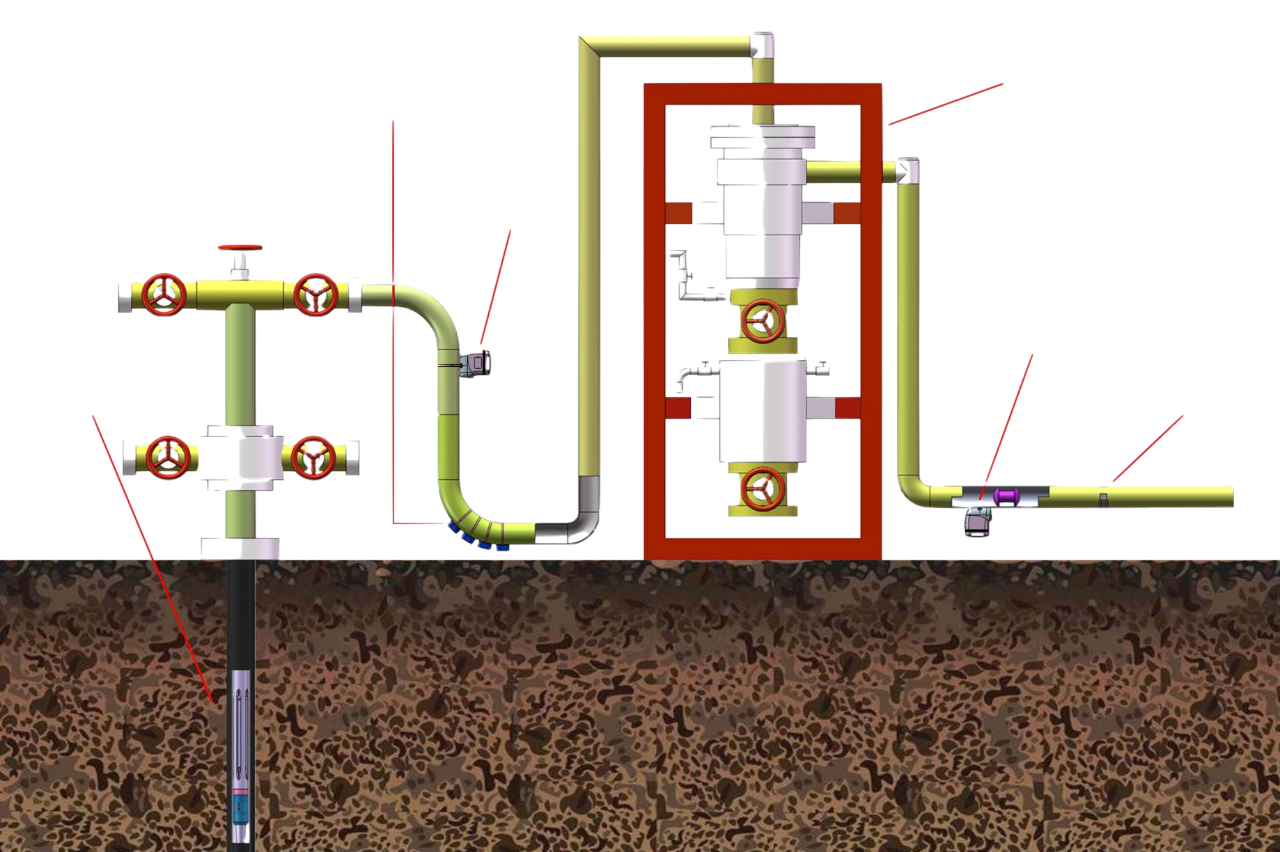

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p

When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP).

The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP). The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion.

The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion. Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials.

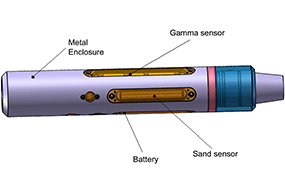

Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials. The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc

The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring The Duke photoacoustic spectroscopy greenhouse gas analyzer

The Duke photoacoustic spectroscopy greenhouse gas analyzer

An All-Round Tool for Catalytic Research

An All-Round Tool for Catalytic Research Infrared Photoacoustic Spectroscopy Gas Analyser

Infrared Photoacoustic Spectroscopy Gas Analyser