- Home

-

Product Center

- Photoacoustic Gas Analyzer DKG ONE

- Photoacoustic Spectrum Gas Analyzer in Oil DK-200F

- Battery spontaneous combustion monitoring system DK-BSC 3001 series

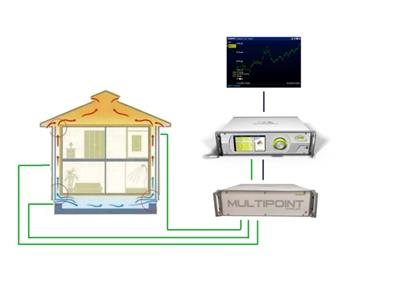

- Tracer Gas Monitoring System for Ventilation DKG-VEN

- SF6 leak Monitoring System For GIS Air Tightness Test

- Online Ozone Gas Analyzer EDK 7100

- Online UV NOx Analyzer EDK7200

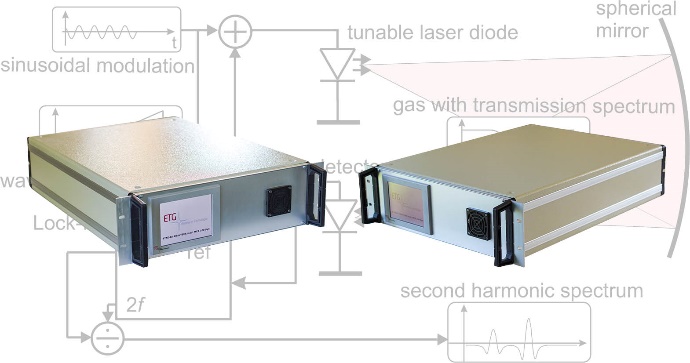

- TDLS Laser microgas analyzer

- Online greenhouse gas flux observation system

- Gasera One trace level photoacoustic spectroscopy multi-gas analyzer

- LP1 laser photoacoustic spectroscopy gas analyzer

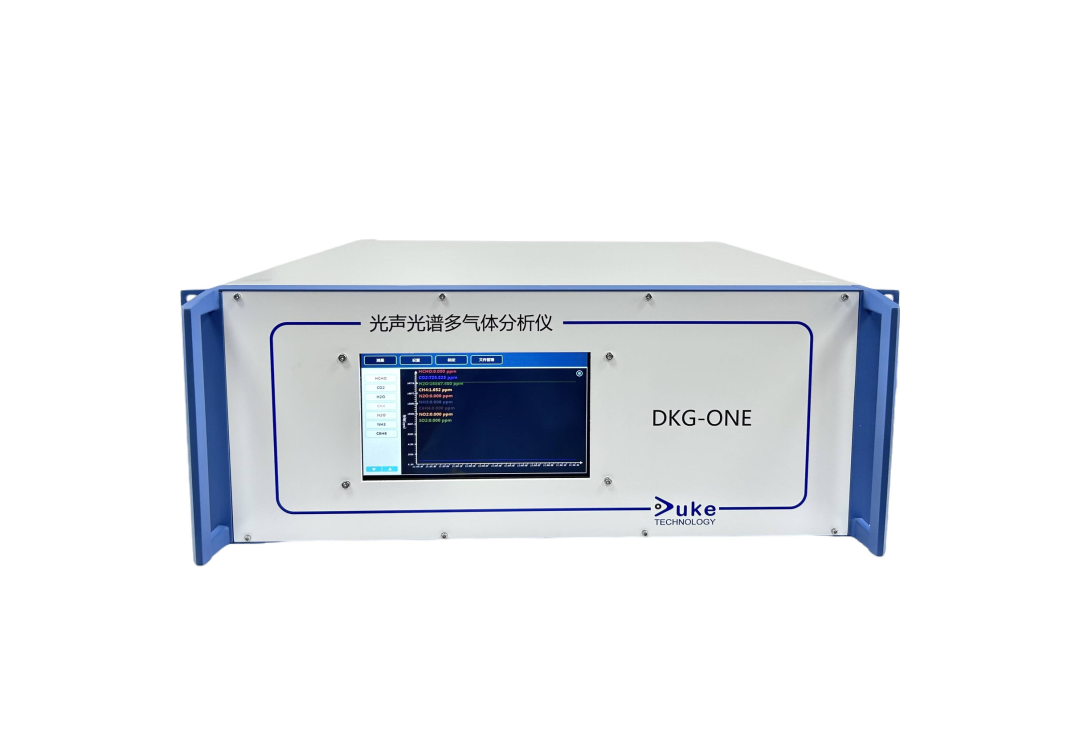

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system.

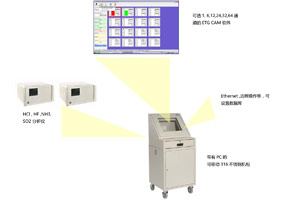

Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system. DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs

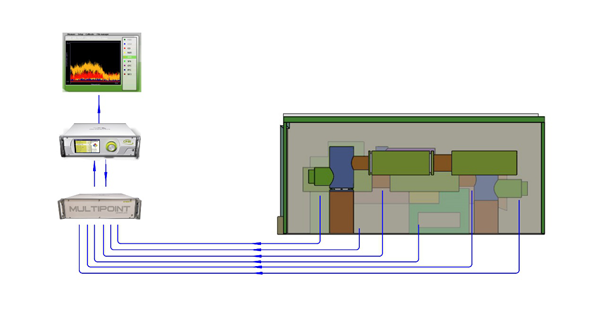

DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency.

Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency. SF6 is widely used in GIS as a good insulation and interruption gas.

SF6 is widely used in GIS as a good insulation and interruption gas.

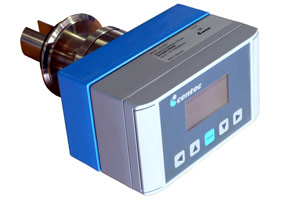

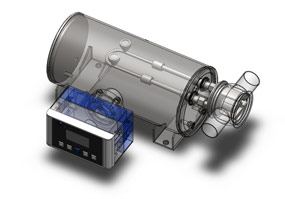

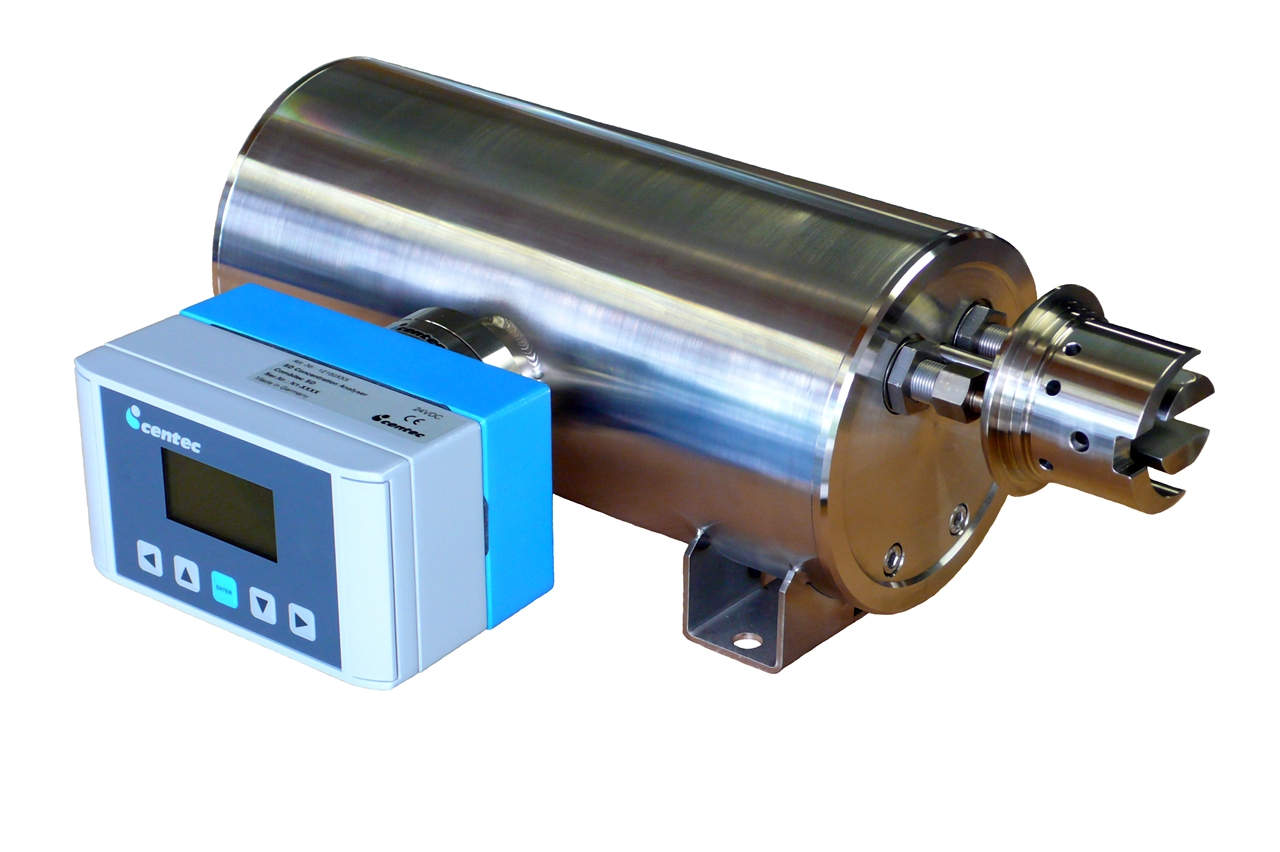

- Dissolved Ozone Analyzer DK-106S

- Online UV Dissolved Ozone Analyzer DK-27TR

- DK-4812 Disposable ozone test strip

- DK-7404S Colorimetric Dissolved ozone tester

- DK-2022S Dissolved ozonometer

- DK-2019S Dissolved ozonometer

- Dk-303 dissolving ozone analyzer with digital display

- DK-505 dissolved ozone analyzer and controller

- DK-MC50 multichannel process analyser

- Dk-46H high precision dissolved ozone analyser

- Portable Dissolved Ozone Analyzer OXYTRANS TR Transmitter Version

- DK-SA 810 Sand Monitoring System

- DK-SA 810 Portable Sand Monitoring System

- DK-SA 810 Compact Sand Monitoring System

- DK-SA 810 Solar-powered Wireless Sand Monitoring System

- DK-SA 810 Wall/Rack Mount Sand Monitoring System

- DK-SA 820 Pigging Indicator

- DK-SA 830 Gas-Solid Separator

- DK-SA 840 Pipe Thickness Monitor

- DK-SA 850 Downhole Sand Monitoring

- DK-SA 860-S Series Vibration Sensor

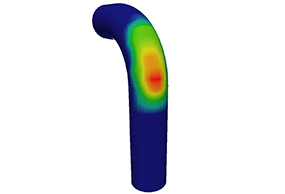

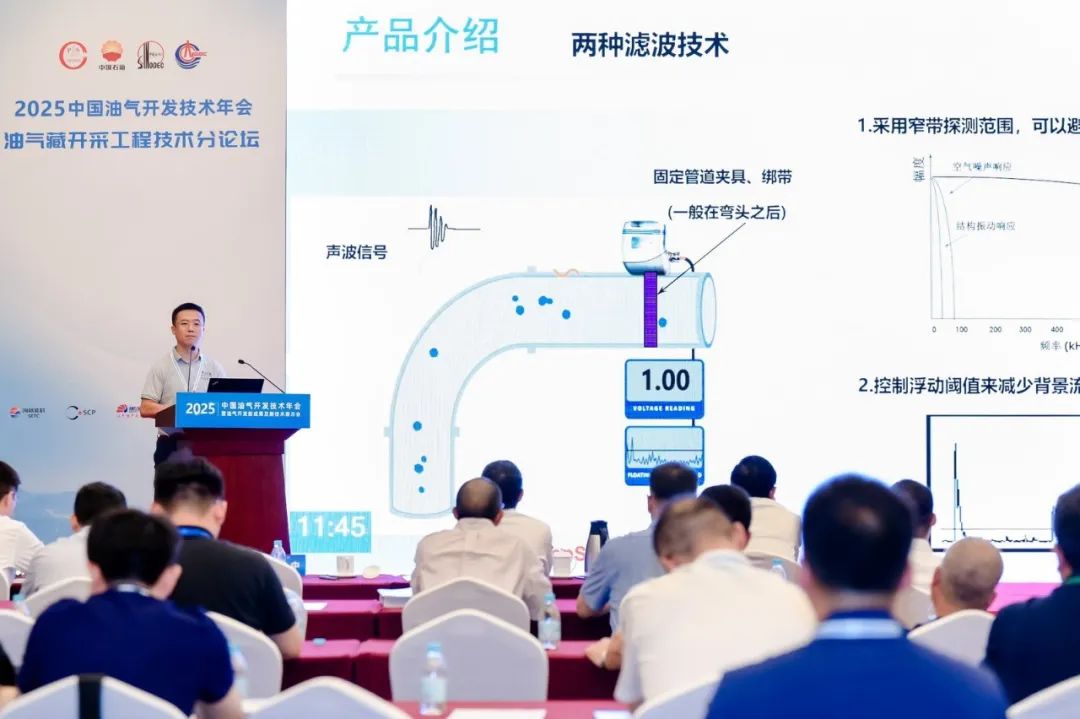

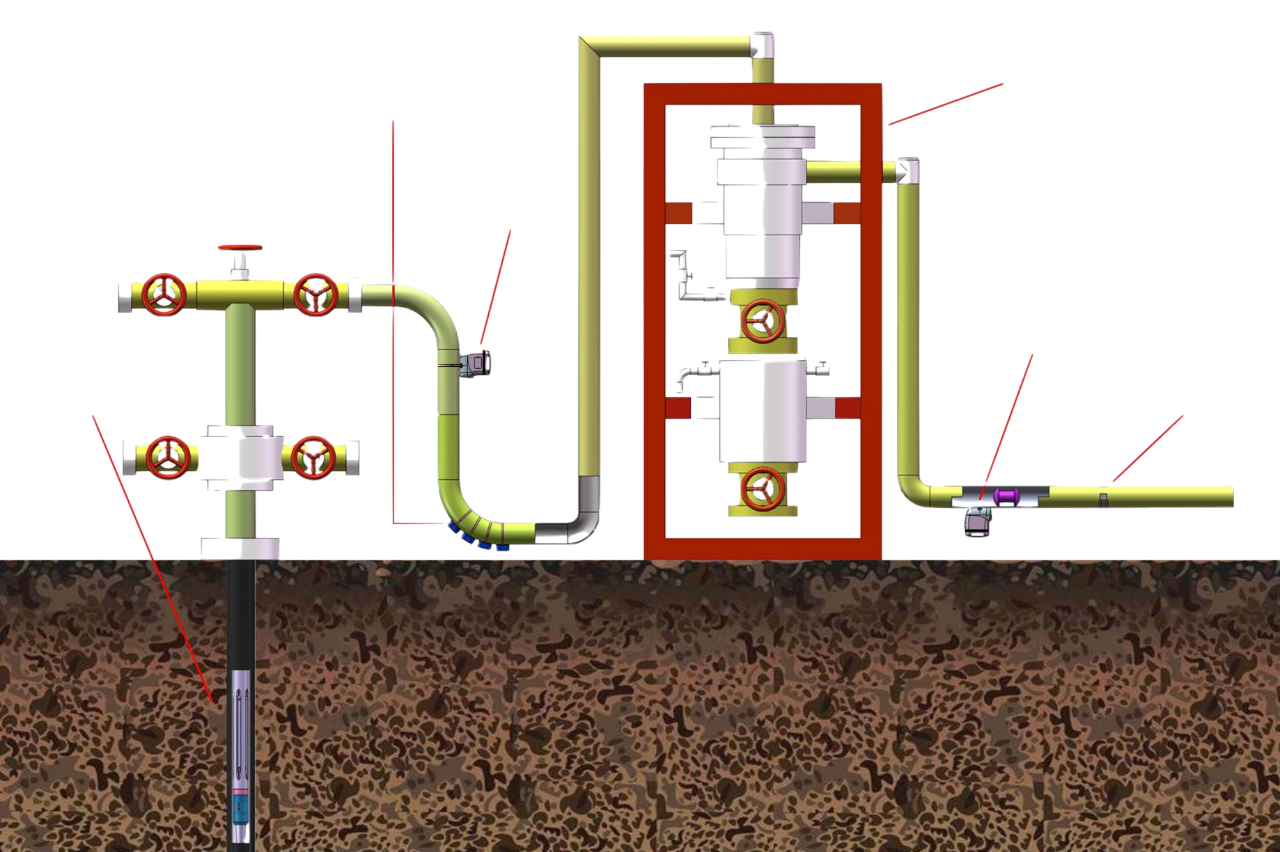

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p

When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP).

The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP). The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion.

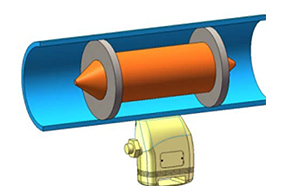

The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion. Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials.

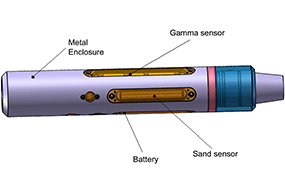

Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials. The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc

The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit - Industry application

- Service support

-

News information

- Duke made its appearance at the 5th Mineral Materials Exchange Conference, and both new and old customers continued to pay attention to the photoacous

- The New Quality Productivity Seminar was a great success, with Duke Technology showcasing its innovative capabilities in gas analysis technology.

- EDK 9500 Series Fourier Transform Infrared Gas Analyser — Making Gas Monitoring More Efficient and Reliable

- Photoacoustic Spectroscopy Trace Phosgene Analyser — The ‘Invisible Guardian’ of Hazardous Gases

- Duke attends the ‘2025 China Oil and Gas Development Technology Annual Conference

- Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer

- Photoacoustic spectroscopy greenhouse gas analyzers contribute to global greenhouse gas monitoring

- DukeTech Oil and Gas Pipeline Monitoring Technology Leads the Way in a New Paradigm of Intelligent Health Management for the Industry

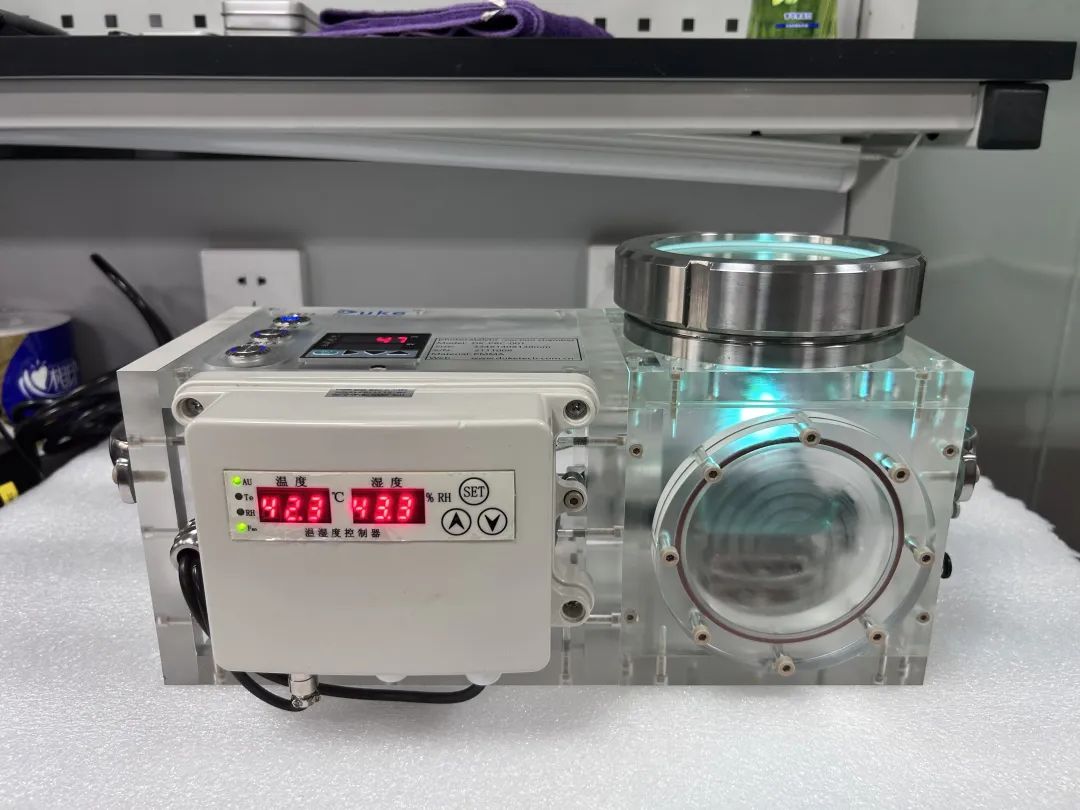

- DK-PRCO10S Series Photothermal Catalytic Reaction Box: An All-Round Tool for Catalytic Research

- Infrared Photoacoustic Spectroscopy Gas Analyser: Precise Detection for Environmental Protection and Scientific Research

- Portable Soil Water and Greenhouse Gas Monitor: Precisely Capturing Ecological Pulses and Empowering New Breakthroughs in Carbon Neutrality Research

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring The Duke photoacoustic spectroscopy greenhouse gas analyzer

The Duke photoacoustic spectroscopy greenhouse gas analyzer

An All-Round Tool for Catalytic Research

An All-Round Tool for Catalytic Research Infrared Photoacoustic Spectroscopy Gas Analyser

Infrared Photoacoustic Spectroscopy Gas Analyser

- Contact us