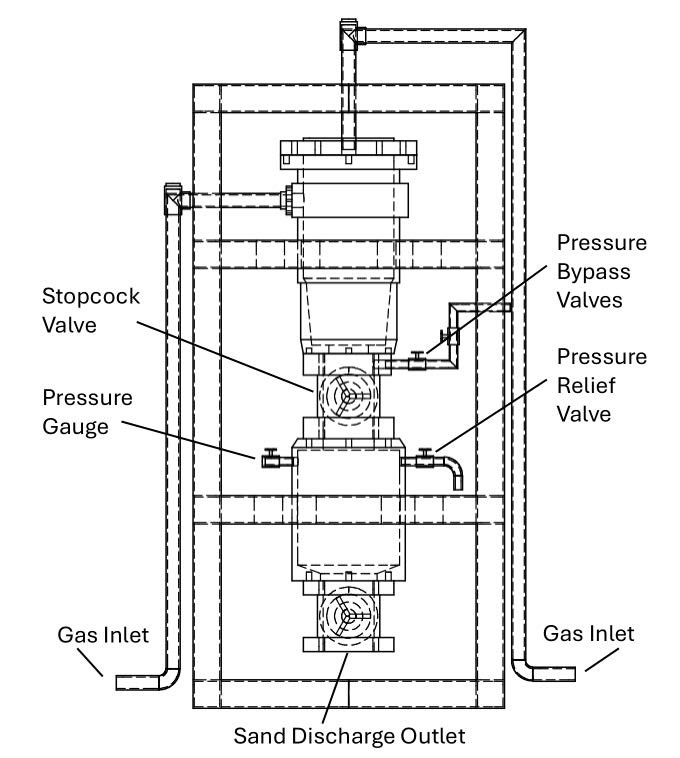

DK-SA 830 Gas-Solid Separator

Overview

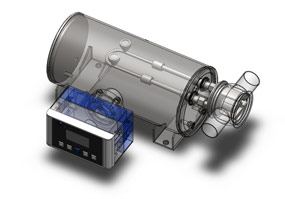

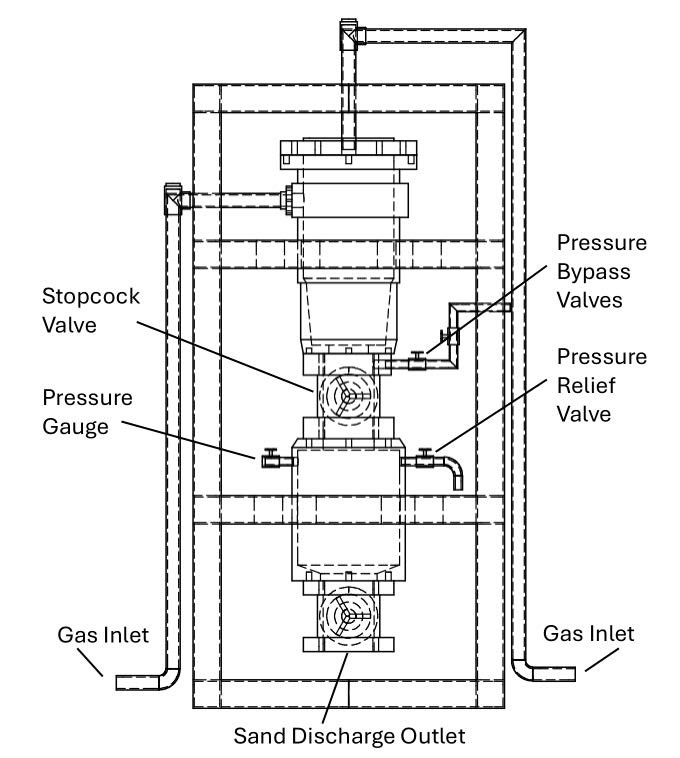

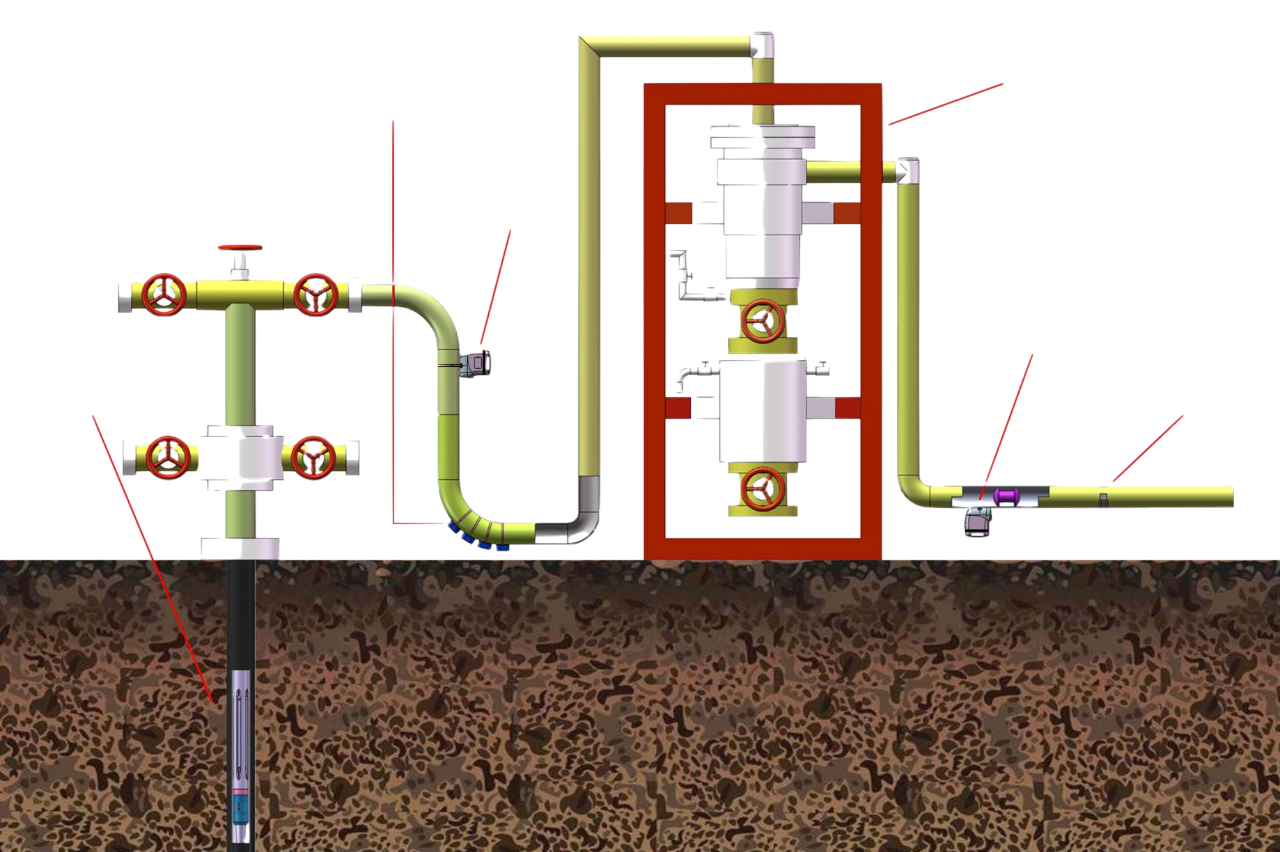

The DK-SA 830 Gas-Solid Separator is widely used in on-shore condensate gas fields at natural gas wellheads and pilot testing sites, as well as in off-shore condensate gas plaƞorm wellheads. The primary purpose of this separator is to remove coarse sand particles from the natural gas produced by gas wells through a swirling motion, thereby protect subsequent processing equipment from damage. Key components of the Gas-Solid Separator include a swirl barrel, a sand settling tank, and supporting process valves. It is also equipped with a safety venting device to ensure safe operation.

Principle

The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion. Due to the differences in fluid density, the forces of centrifugal force, centripetal buoyancy, and fluid drag act differently on the components. This results in the lower-density gas rising and being discharged through the separator outlet, while the higher-density sand is expelled from the sand discharge outlet at the bottom of the device, achieving the goal of sand removal.

Features

l Flexible, Diverse, Customizable

l Utilizes advanced swirl technology for superior sand removal efficiency.

l Small size with high processing capacity, saving on- site space.

l The sand settling tank is designed for ultra-high pressure to ensure safe operation.

l Easy to operate and transport, reliable and safe.

l Capable of accommodating 10~150% fluctuations in natural gas production.

l Can work uninterrupted during operation, avoiding the need to shut down wells for sand removal.

l Prevents secondary contamination of oil quality associated with other sand removal methods, maintaining high sand removal efficiency.

Installation

ü The Gas-Solid Separator should be installed on the main pipeline of the gas supply network and secured to a base. A bypass should be added between the separator outlet and the sand settling tank.

ü When installing the Gas-Solid Separator, ensure there is sufficient maintenance space around it.

ü During normal operation, the plug valve between the swirl barrel and the sand settling tank must be opened, while the sand discharge valve and bypass valve should be closed.

ü For sand removal, periodically discharge sand based on the sand content in the gas and the pressure indicated on the sand settling tank pressure gauge. First, close the plug valve between the sand settling tank and the Gas-Solid Separator, then open the pressure relief valve. When the pressure in the sand settling tank reaches zero MPa, open the sand discharge valve. The sand removal process should not affect the normal operation of the system.

ü After sand removal is complete, first close the sand discharge valve and the pressure relief valve. Then, open the bypass valve for the sand settling tank. Once the pressure in the sand settling tank stabilizes with that in the swirl barrel, open the plug valve and close the bypass valve.

Technical Parameters

Natural Gas Processing Range: | > 1200 m³/h | Solid Removal Rate: | 99% |

Working Temperature: | -20℃~+100℃ | Environment: | acid -resistant sulfur-resistant |

Designed Pressure: | 42 MPa | Working Pressure: | < 30 MPa |

Container Weight: | 8000 kg | Volume: | 3.7 m³ |

Container Shell Material: | Q245R |

|

|

Dimensions: | 1000mm x 1000mm x 3600mm |

|

Appearance Indicators: | Sandblasted and polished, inorganic zinc primer, epoxy resin intermediate coating, acrylic polyurethane outer coating. |

Processing Capacity: | Gas phase: over 1.2 million standard cubic meters per day at maximum pressure |

| Liquid: 800 m³ per day with a 2-minute delay time. |

*Customization available according to user requirements*

Applications

Used in oil and gas extraction, oil field drilling, coalbed methane drilling for mud purification and swirl separation, sand removal from river water and well water, washing coal water, industrial mineral processing, solid-liquid separation, liquid degassing, and separation of immiscible liquids.

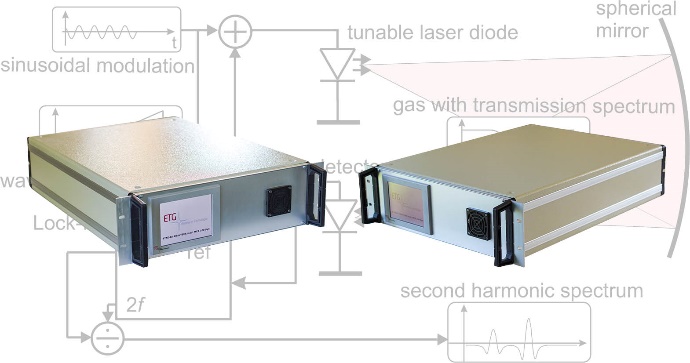

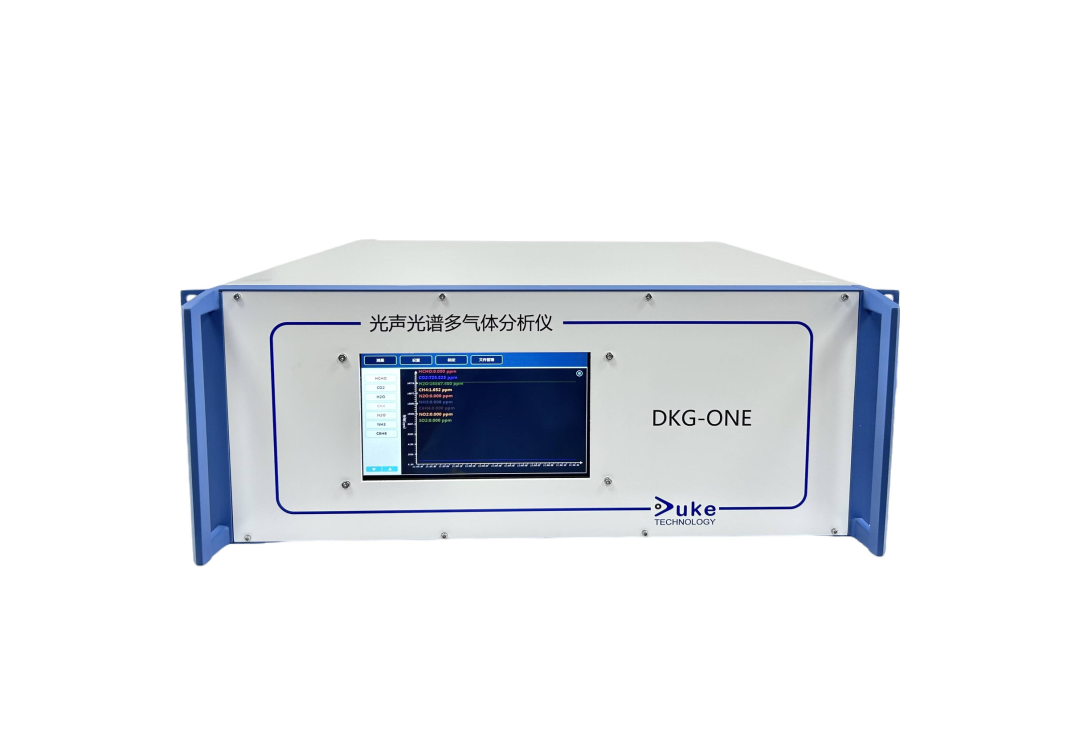

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system.

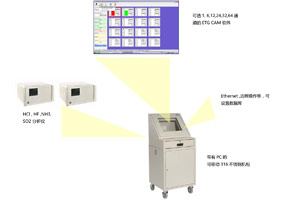

Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system. DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs

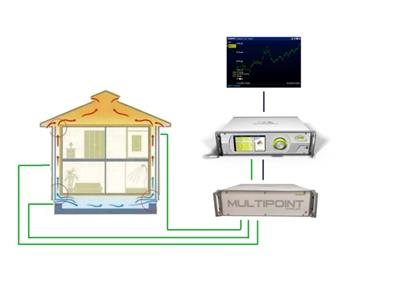

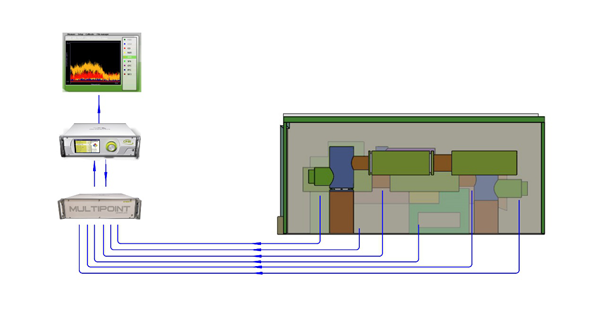

DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency.

Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency. SF6 is widely used in GIS as a good insulation and interruption gas.

SF6 is widely used in GIS as a good insulation and interruption gas.

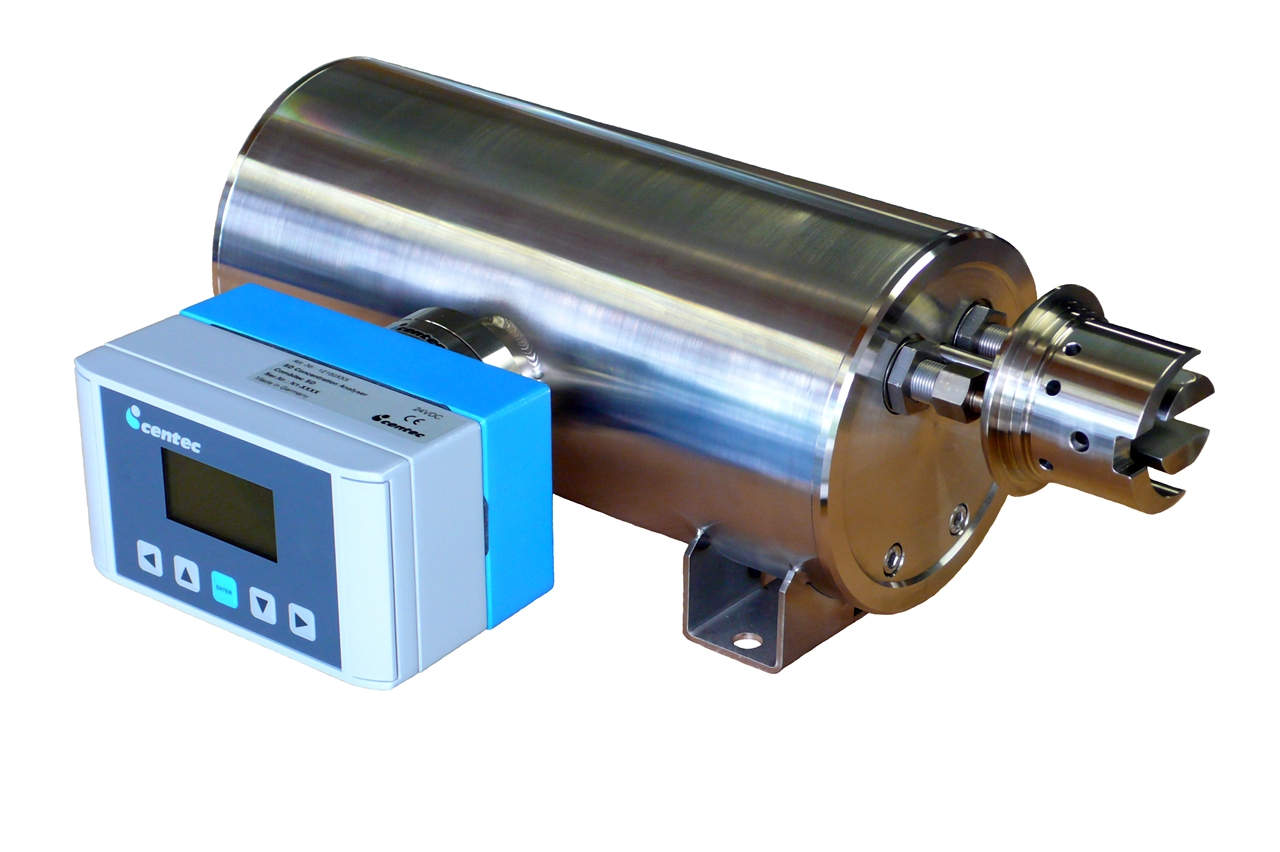

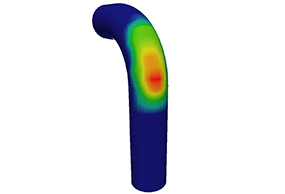

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys

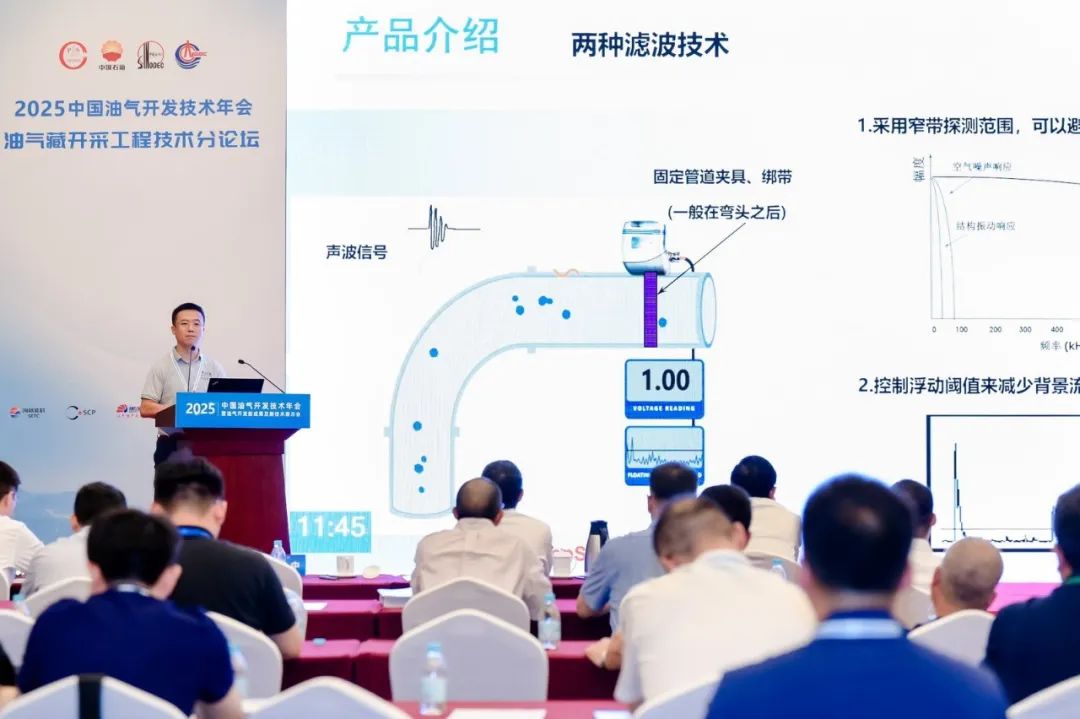

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p

When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP).

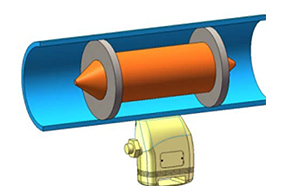

The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP). The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion.

The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion. Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials.

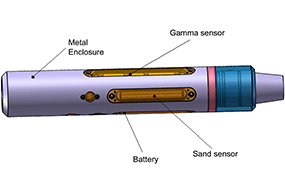

Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials. The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc

The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

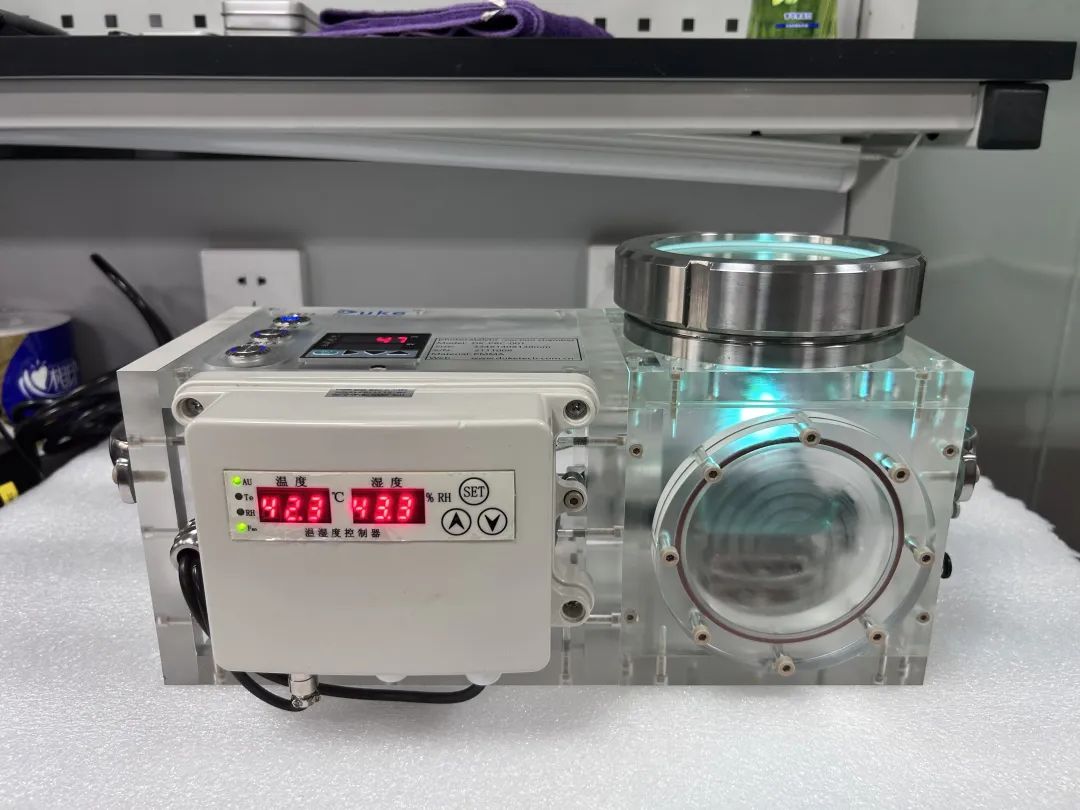

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring The Duke photoacoustic spectroscopy greenhouse gas analyzer

The Duke photoacoustic spectroscopy greenhouse gas analyzer

An All-Round Tool for Catalytic Research

An All-Round Tool for Catalytic Research Infrared Photoacoustic Spectroscopy Gas Analyser

Infrared Photoacoustic Spectroscopy Gas Analyser