DK-SA 820 Pigging Indicator

Overview

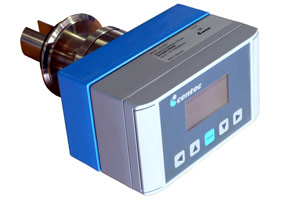

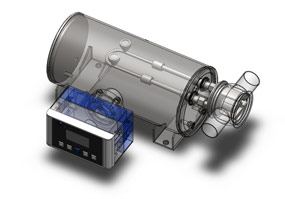

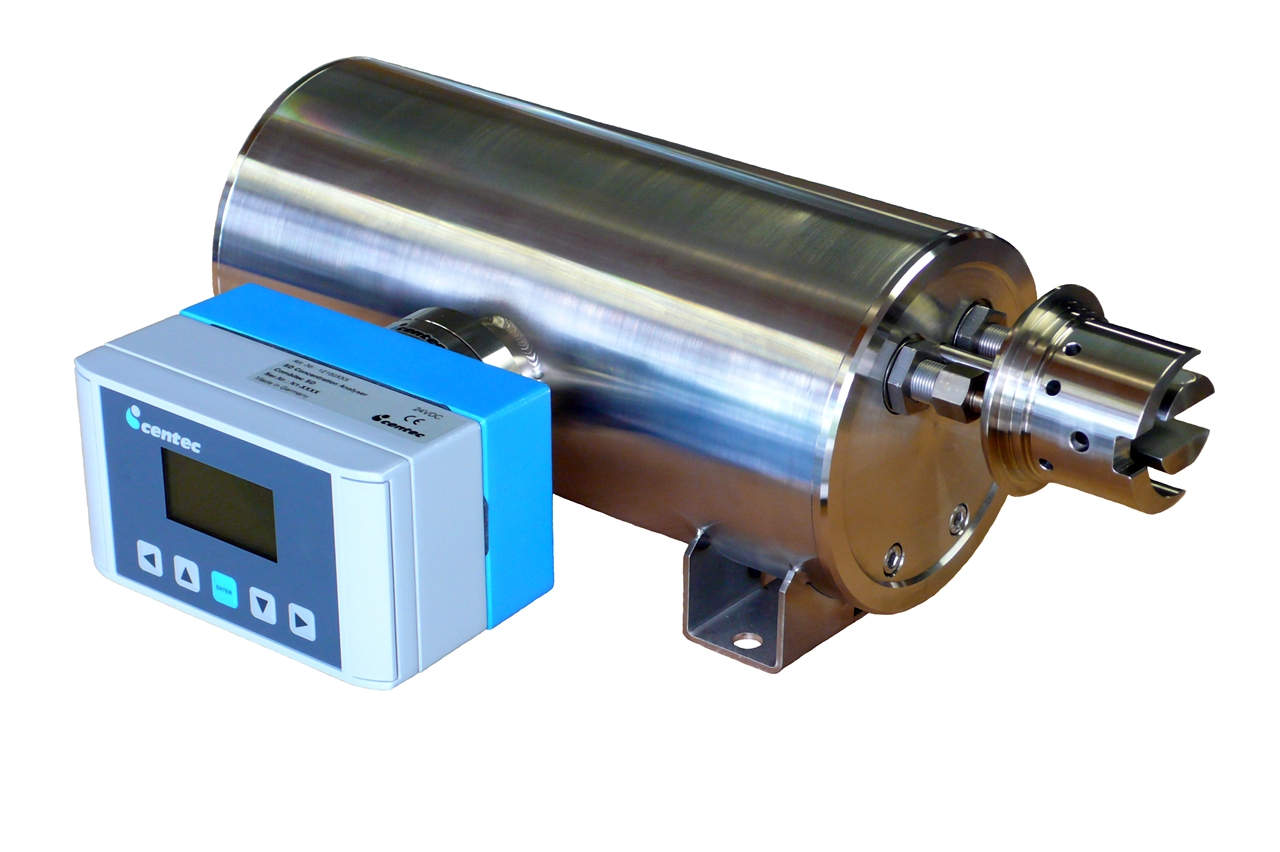

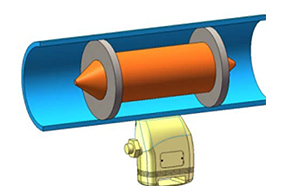

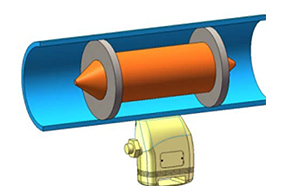

Pigging is part of the routine operations for many offshore and onshore facilities. Operators need a reliable method to confirm that the pig has left the pig launcher or to verify its arrival at the receiver. The DK-SA 820 series pigging indicator is based on our patented ultrasonic intelligent sensor technology platform, featuring a compact structure and ease of use. Its quick and simple installation principle is unmatched by other pigging indicators. Furthermore, it can accurately and reliably detect all types of pigs without any inserts.

Principle

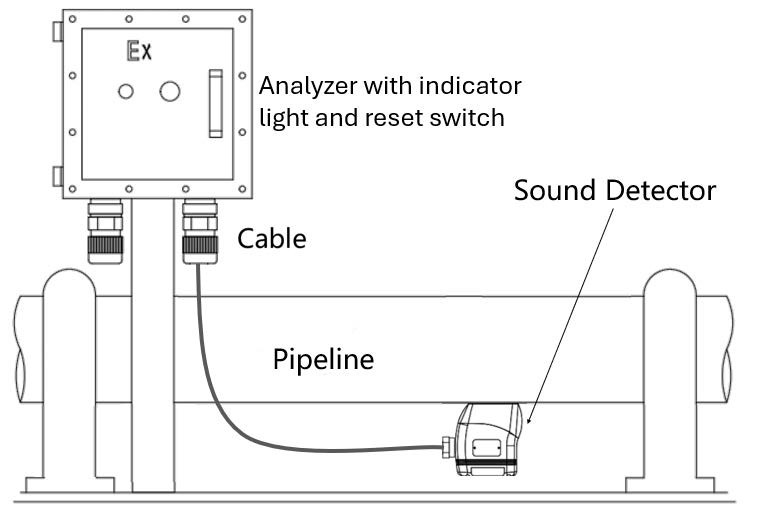

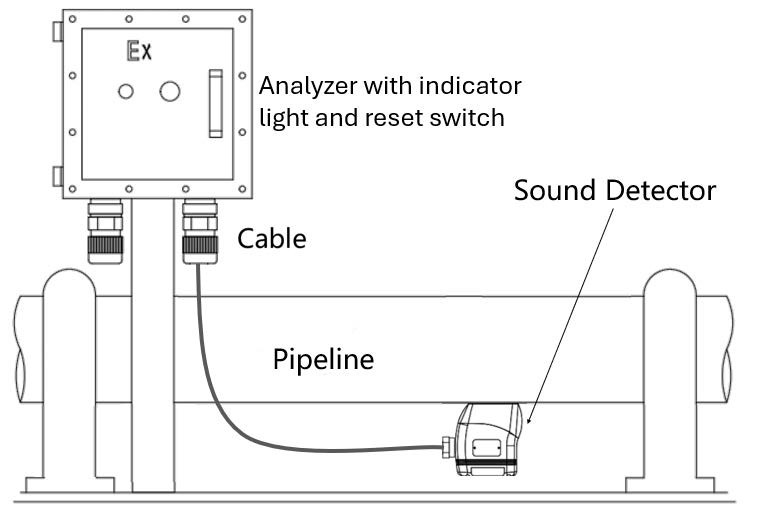

The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP). When the pig passes the detector's position, it detects and analyzes signal level changes at multiple frequencies. The indication of the pig's passage can be displayed on a local light on the instrument or through signals output to the control system or indicator panel. The signal output indicates "Pig Passed" (e.g.,relay contacts) or raw pig passage data for further analysis. By using a computer equipped with Duke's proprietary software or by inputting data into the main control system, users can obtain graphical displays of the signals received from the detector. The output is 4-20mA analog or RS485 digital signal.

Advantages

l Real-time measurement

l Non-intrusive

l Easy to install

l Modify without showdown

l local or remote indication

Installation

The Duke pigging indicator (pig detector) features a non-intrusive design, clamping onto the surface of the pipeline without any parts in contact with the fluid. All instruments are calibrated and tested before leaving the factory. The sensor is used to detect pigs traveling through the pipeline where the sensor is located, available in both intrinsically safe and explosion-proof versions, and can be easily installed on pipelines of various sizes using relevant mounting devices. Installation on existing pipelines does not require hot work permits. The sensor is best installed on the underside of the pipeline to achieve optimal signals in low-flow conditions. The Duke DK-SA 820 series pigging indicator is not affected by flow rates (below 30m/s), so changes in flow rate over time have minimal impact on measurement results. This system requires at least one pair of cables for local lighting or two pairs of cables for detector signal output.

The sensor can also be equipped with an indicator light (which lights up when the pig has passed) and a reset button.

Technical Parameters Sensor

l Principle: Intelligent Acoustic Sensor

l Installation: Clamp-on (Non-intrusive)

l Protection: IP56, IP65, IP66, IP68 (Optional)

l Ambient Temperature: -40℃ to 60℃ [-40℉ to 140℉]

l Pipeline Temperature: -40℃ to 150℃ [-40℉ to 300℉]

l Accuracy: ±2s

l Power: 24VDC@2.8W, 110/240VAC 50/60Hz, Solar, Lithium Battery (Optional)

l Docking: M20 Aviation Connector, 1/2" NPT

l Output: 2 Alarm Relays, 4-20 mA/0-20 mA Analog, RS-232, RS-485 (Modbus RTU, Profibus Protocol)

l Alarm Indication: Relay, Local Light, External Light, MCS, 4-20 mA, via RS485 connection to Modbus

l Material: 316 Stainless Steel

l Weight: Ex ia<3kg, Ex de/m <8kg

l Software: Windows-based Analysis Testing Software, Embedded (Optional)

l EPC: Ex db ia [ia IIC Ga] IIB T6 Gb

Controller

Fixed Installation |

Power: | 110/240VAC@50/60Hz、24VDC@15W | Software: Docking: | Linux based, embedded |

Temperature: | -40℃~+70℃ | M20 Aviation Connector, 1/2" NPT |

EPC: | EEx ia IIC T6 ,EExia IIC T4, ExdIIBT4 |

|

|

Output: Analog 4-20mA/0-20mA @ 500 ohms (Tunable) 0.1% Accuracy |

Wall-Mount: | Size: 240x184x118mm Material: 316L Stainless Steel Protection: IP56, IP65, IP66, IP68 Weight: 10kg |

Portable |

Power(Charging): Lithium Battery, Runtime > 24 Hours | Tamperature: | -40℃~+70℃ |

Accuracy: | 0.01g/s (optional 0.001g/s) | Storage: | 25Years (32GB storage card) |

EPC: | ATEX EEx ia IIC T6, EEx ia IIC T4, EExia IIB T4, Exd IIBT4 |

|

Output: Digital, RS485 Modbus, Ethernet HMI: 7" LCD Touch Screen |

Protection: | IP65 (w/ case closed), IP50 (case opened) | Size: 406x330x1 | 74mm |

Wireless |

Power(Charging): Lithium Battery, Runtime > 48 Hours | Tamperature: | -40℃~+70℃ |

EPC: | ATEX EEx ia IIC T6, EEx ia IIC T4, EEx ia IIB T4, ExdIIBT4 |

|

Output: | Digital, RS485 Modbus, Wireless;4G, 5G, LORA, ZigBee, Bluetooth, WiFi, optional |

Protection: | IP56, IP66, IP68 (optional) Size: 600x300x1500mm |

|

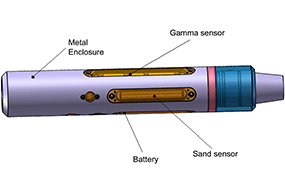

Underwater Pigging Indicator

| Compact | Deepwater |

Depth | 1500m | 3000m |

Max Operation Pressure | 200bar | 400bar |

Max Testing Pressure | 300bar | 600bar |

Enclosure | UNS S31803 Duplex SS or Titanium | UNS S31803 Duplex SS or Titanium |

Size (w/o ROV handle) | Ø100×400mm | Ø150×500mm |

Weight | 7kg | 18kg |

Jumper/Bulkhead | Bennex/ODI | Bennex/ODI |

Connectors | 12-Pin EFL/TRONIC/RMS with SCM | 12-Pin EFL/TRONIC/RMS with SCM |

Independent Component | YES | YES |

EB Welding | YES | YES |

Glass-Metal Penetrator | YES | YES |

L/H Pressure Chamber | YES | YES |

ROV Installation/Recycle | YES | YES |

Fixture/Protective Sleeve | YES | YES |

Power Supply | 12-28VDC | 12-28VDC |

Current | 100mA@24VDC | 100mA@24VDC |

Lifespan (MTBF) | 220000 Hours | 220000 Hours |

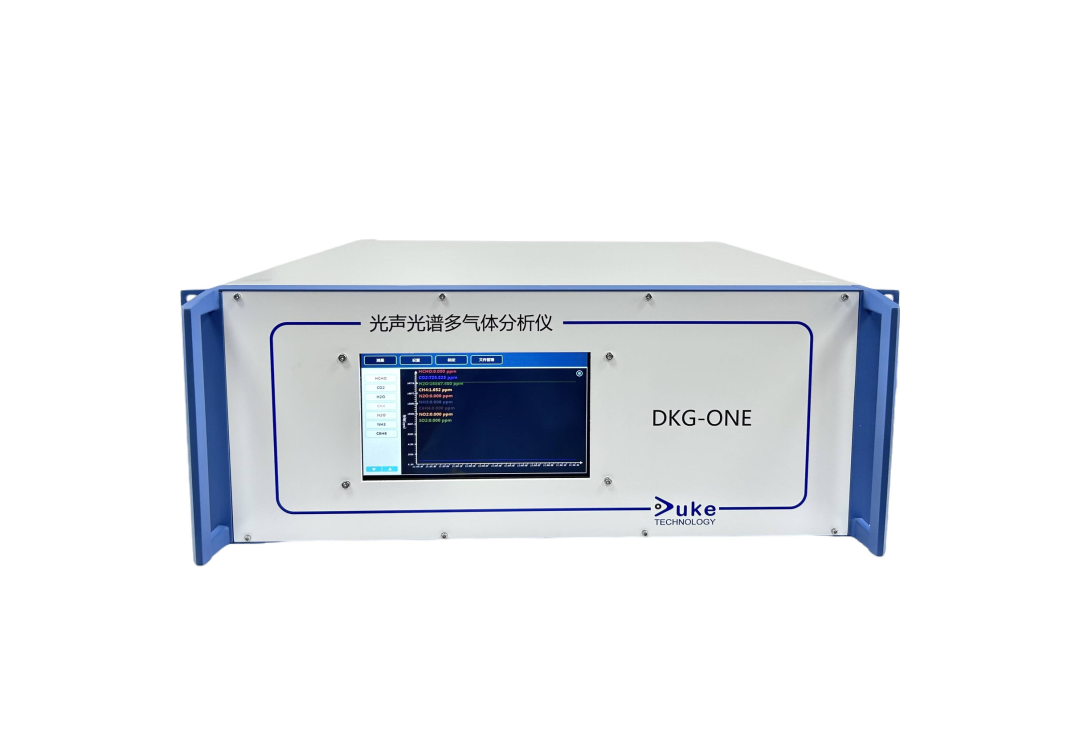

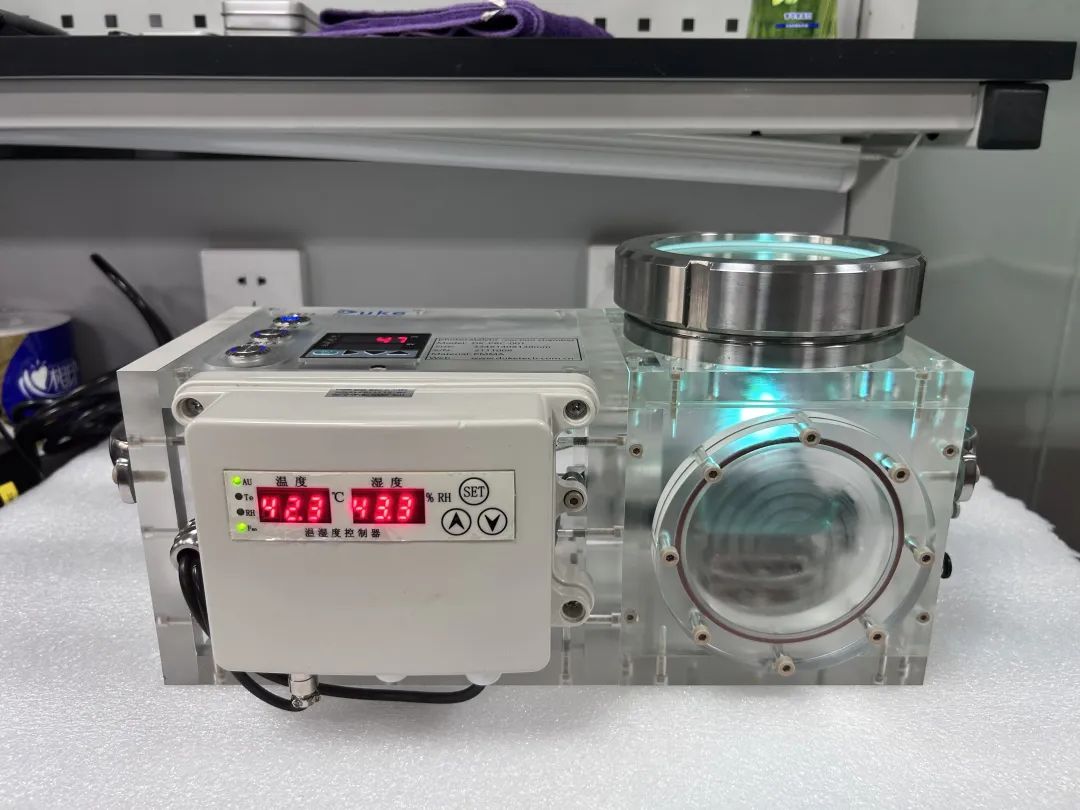

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system.

Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system. DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs

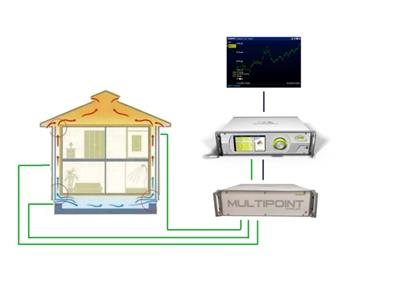

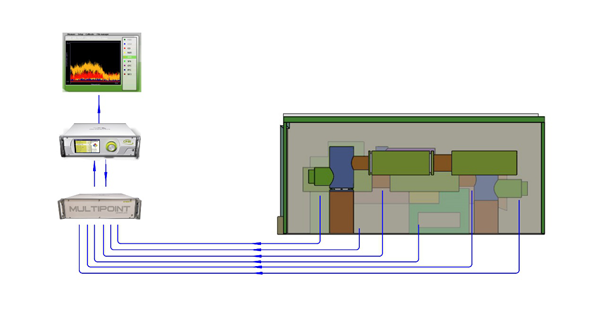

DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency.

Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency. SF6 is widely used in GIS as a good insulation and interruption gas.

SF6 is widely used in GIS as a good insulation and interruption gas.

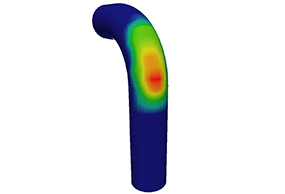

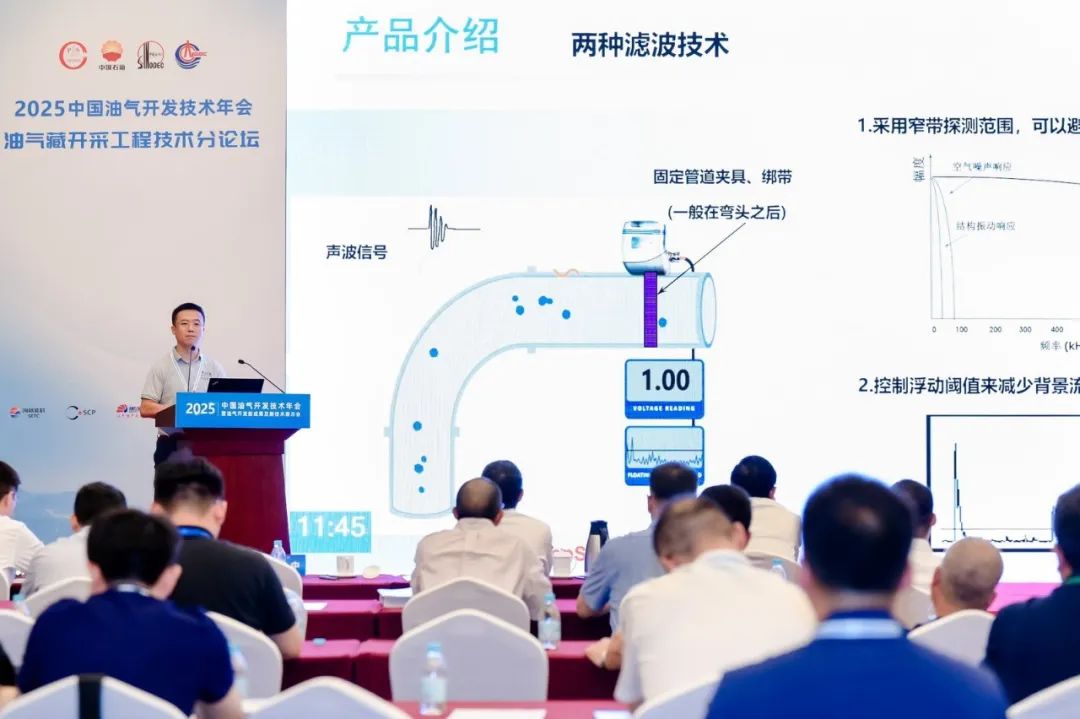

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p

When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP).

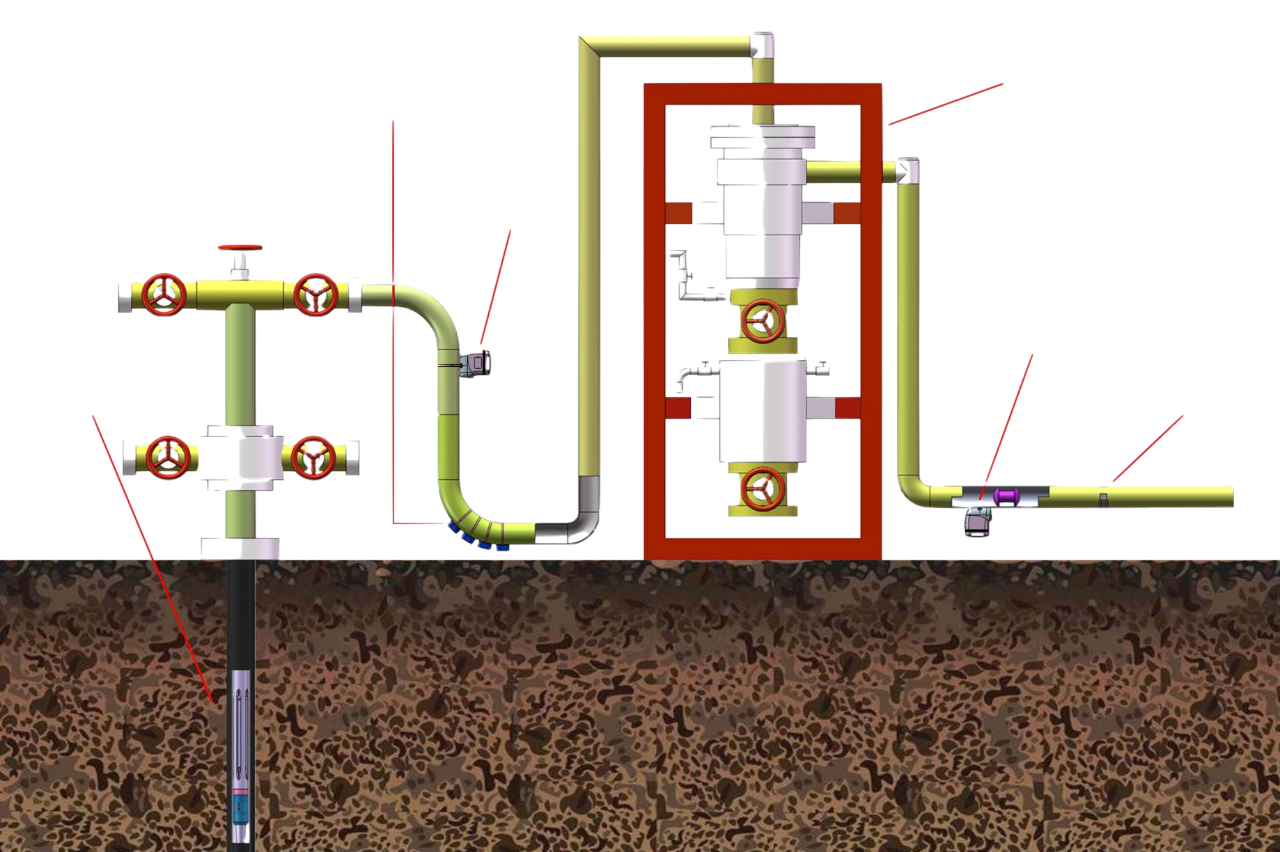

The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP). The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion.

The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion. Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials.

Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials. The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc

The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring The Duke photoacoustic spectroscopy greenhouse gas analyzer

The Duke photoacoustic spectroscopy greenhouse gas analyzer

An All-Round Tool for Catalytic Research

An All-Round Tool for Catalytic Research Infrared Photoacoustic Spectroscopy Gas Analyser

Infrared Photoacoustic Spectroscopy Gas Analyser