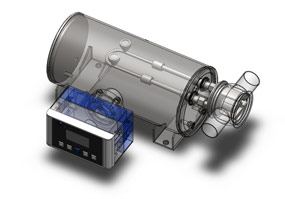

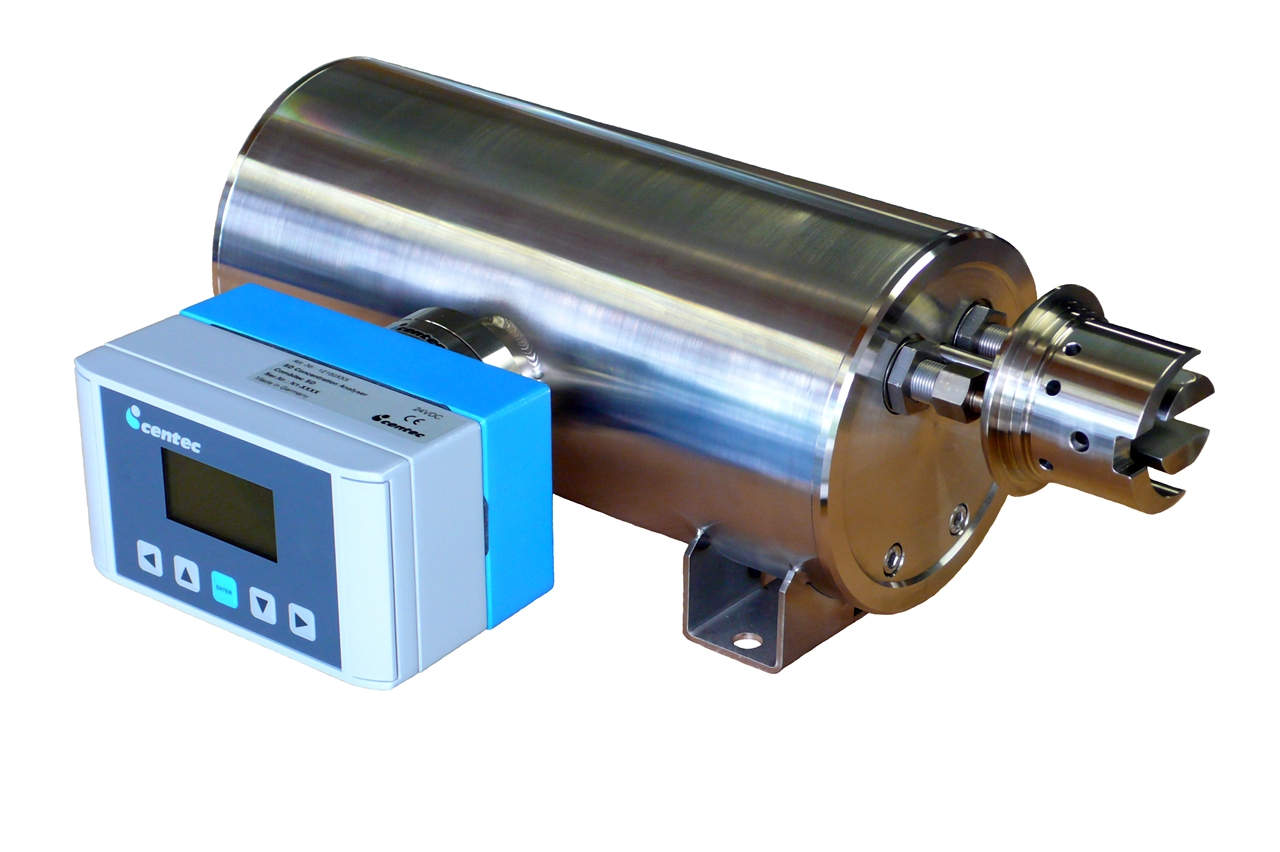

EDK 6700 fuel gas multi-component analyzer

• BTU/Wobbe content measurement

• C1-C5 hydrocarbon separation & total gas analysis

• Continuous flow-through analysis

• Very fast response

•New technology based on IR TF

• Any carrier gas or utilities

• Alternative to GC technique

• Permanent Span calibration

Online monitoring of calorific value in fuel gases

The Wobbe Index (WI) expresses the heating value (known as calorific value) of gases used as fuels, taking into account the proportionality of calorific value to the specific gravity, or the density ratio between the given fuel gas and air. More precisely, the specific gravity is proportional to flow velocity through a constant orifice size at a constant pressure, and thus proportional to gas calorific value. The ETG 6700 puts continuous Wobbe Index monitoring and control in the hands of fuel gas producers, distributors, or anyone requiring WI readings for process optimization.

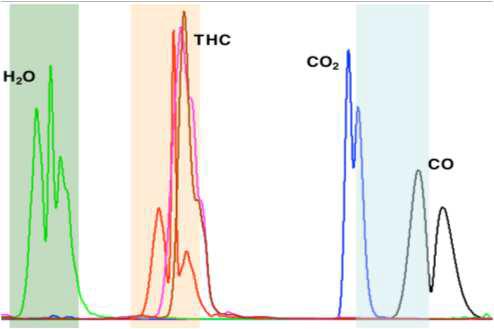

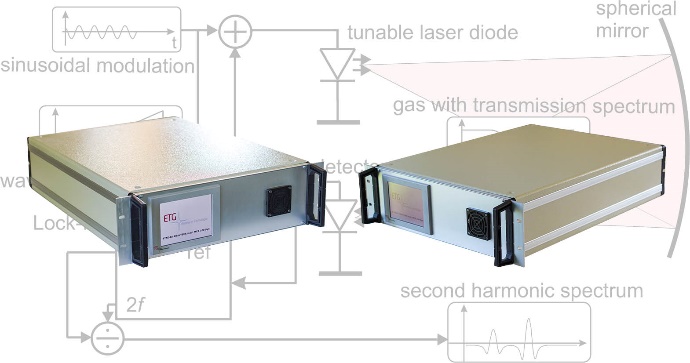

Basically the ETG 6700 it’s a Tunable Filter I.R. Analyser is an infrared absorption-based on line monitoring system, configured for measurement of light hydrocarbons (alkanes, alkenes and alkynes). A real-time optical analyser, the ETG 6700 is capable of accurately separating hydrocarbon components, a process which could previously only be performed by gas chromatograph (GC) analysers.

The technology Spectroscopic – Advanced NIR/IR absorption spectroscopy utilises state of the art spectral scanning and chemometric based data processing for exceptionally high accuracy, low cross sensitivity and a very fast speed of response. A flow-through cell utilises a patented spectrometer design for a highly stable and accurate measurement; an advanced Tuneable Filter Spectroscopy Analysis Algorithm delivers industry-leading interference compensation with a permanent span calibration, low cross-interference, high baseline stability and a linear response.

Main Applications Natural gas quality and composition, BTU/Wobbe Index measurement, Fuel Blending and control, Gas turbine,engines,fuel cells, Biogas and Syngas fuel, Blast furnace gases, Biomethane production, Natural gas quality, Air demand for combustion control, Refineries flare stacks, etc….

• Non-Contact Flow-Through Gas Cell

• No sensor poisoning

• Long-term stability

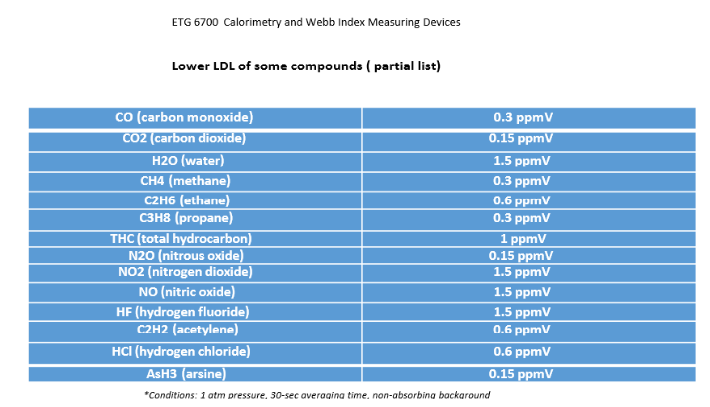

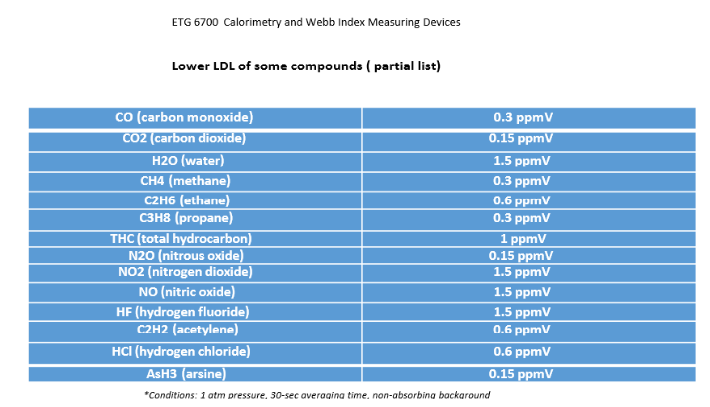

ETG 6700 is an infrared absorption based on-line monitoring system configured for measurement of hydrocarbon and VOC gases; including alkanes, alkenes, alkynes, alcohols, aldehydes and aromatics at ppm to percent levels.

Non-Contact Flow-Through Gas Cell

• no sensor poisoning

• long-term stability Versatile Optical Platform

• UV through IR wavelength regions

• various light sources can be coupled High Etendue Optical System

• high optical throughput

• high sensitivity

• excellent signal:noise

• fast measurement (<1second)

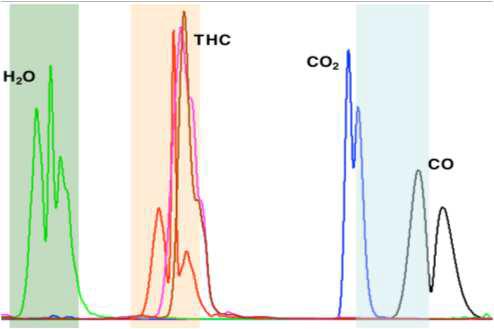

• opaque liquid & solid measurement Wavelength Scanning

• simultaneous multi-compound

• high stability and selectivity Figure showing the highly overlapped spectra

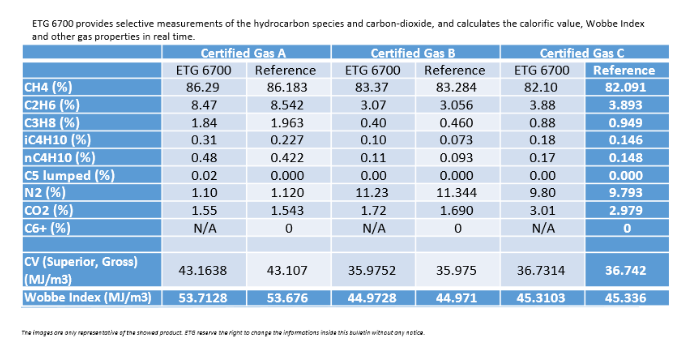

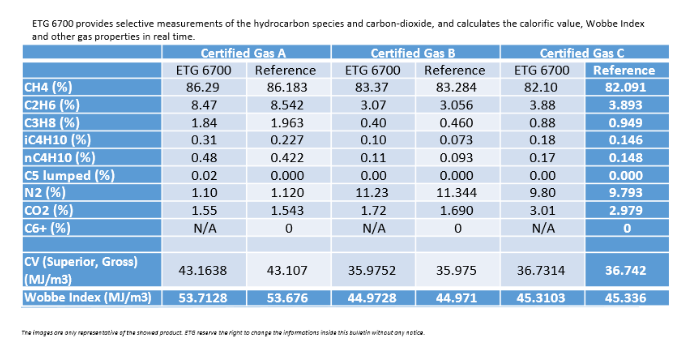

ETG 6700 provides selective measurements of the hydrocarbon species and carbon-dioxide, and calculates the calorific value, Wobbe Index and other gas properties in real time.

The ETG 6700 it’s composed mainly by the Tunable Filter Spectrometer which’s capable of high-accuracy fuel gas composition measurements every 5 seconds. The ETG 6700 Gas Analyzer provides selective measurements of the hydrocarbon species and carbon-dioxide, and calculates the calorific value, Wobbe Index and other gas properties in real time. The analyzer provides real-time data through Modbus digital interfaces.

Other components are :

• IR Optical Bench for additional measurement of CH4,CO2,CO

• ARM processor with ETG proprietary SW

• 5,7 “ Touch Screen Monitor

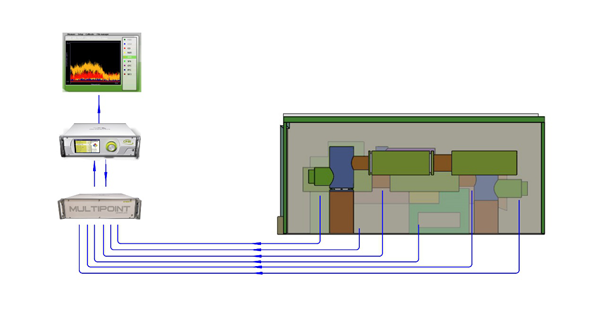

• DO module for MPS (Multipoint System )

• Analog Output for speciate or Calorimetric value by 4-20 mA

• Gateway Converter for ModBus, Profibus

The ETG 6700 Gas Analyzer provides an accurate and real-time alternative to gas chromatographs and residual oxygen analyzers for monitoring fuel gas composition and heating value properties including liquid natural gas (LNG), pipeline natural gas, and other fuel gases containing C1 – C5 hydrocarbons. Factory calibrated, the analyzer provides<0.15% relative CV accuracy in LNG type sample containing only C1 – C5 and < 1% error in pipeline natural gas samples containing C6+ heavier hydrocarbons

ETG 6700 Gas Analyzer specifications in Natural Gas Analysis Configuration

Compounds Measured

Methane, Ethane, Propane, n-Butane, iso-Butane, C5 (lumped), CO2 (0-100%) BTU, CV Wobbe Index Precision / Repeatability * < +/- 0.05% (repeatability based upon 5-second averaging)

Accuracy *- Methane (80-100%): +/- 0.2%, Methane (0 – 80%): - +/- 0.5% Ethane & Propane: +/- 0.2% - iso & n-Butane: +/- 0.1% - Pentanes: +/- 0.2% - CO2: +/- 0.2% Zero drift Less than ±0.2% (absolute) per month (zero on air or N2)

Span calibration Factory calibrated (permanent calibration for the life of the analyzer)

Update rate 5 seconds (default) or 1-300second configurable (averaging time improves precision)

Additional channel(s) Contact ETG for additional target gases

Technique Flow through

Flow rate 0.1 – 1 SLPM (up to 15 SLPM available upon request)

Pressure* 0 – 5 psig (up to 100 psia available upon request)

Sample temperature 0-50 °C

Sample connections ¼” SwagelokTM fittings

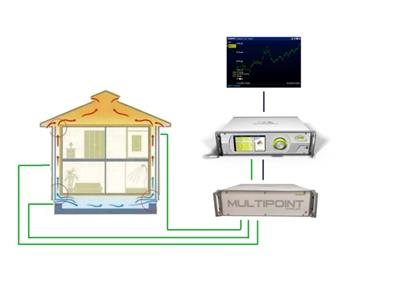

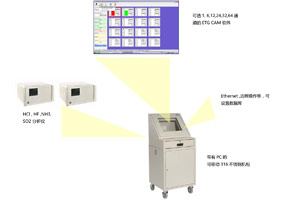

Multipoints Up 6 differentsampling points

Electrical Signal Output 4-20 mA for each measuredgas or as Wobbe Index

CommunicationProtocol ModBus RTU, ModBusTCP IP, Profibus, Profinetand others on request

Multisampling System Signal D.O. for each measuredpoint driven by SW

Mechanical dimensions The dimensions dependingby APPLICATION and CONFIGURATION

Weight 18 Kg

Power requirements 100-240VAC 50 Hz

Operating temperature -5°C to + 40 °C

Enclosure Material & Protection SS 304 - IP54

ETG 6700 is the Best Solution :

The simplicity of an NDIR-like hardware package, with FTIR-like accuracy & specificity, and GC-like speciation without physical separation

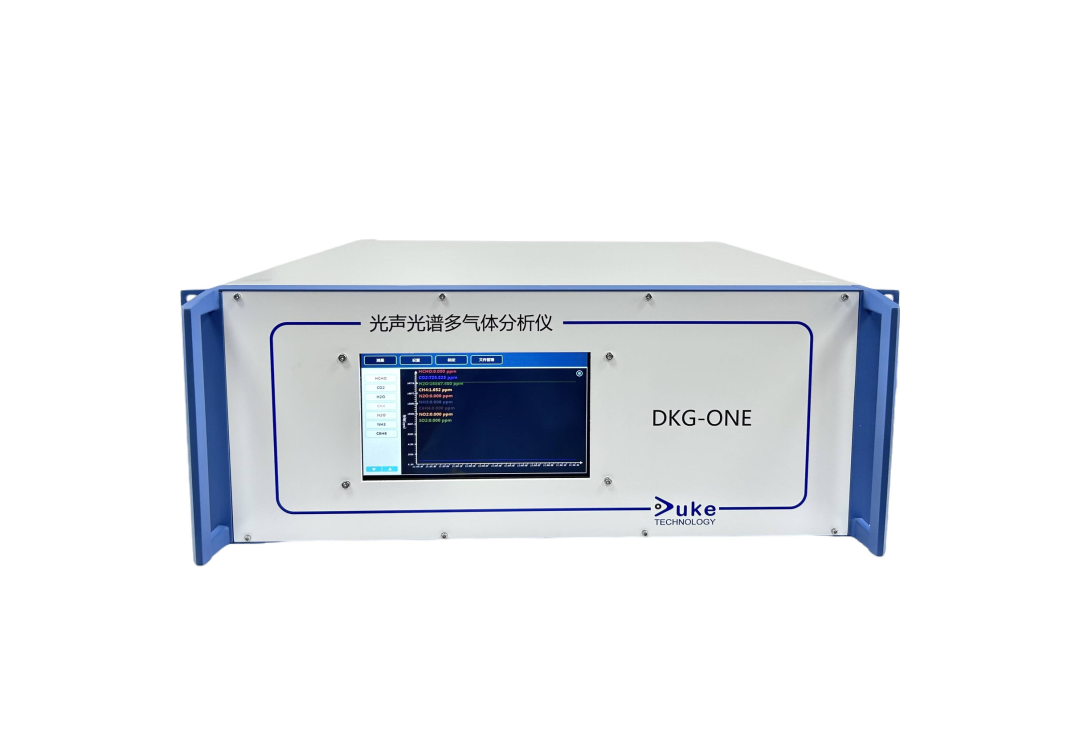

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system.

Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system. DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs

DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency.

Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency. SF6 is widely used in GIS as a good insulation and interruption gas.

SF6 is widely used in GIS as a good insulation and interruption gas.

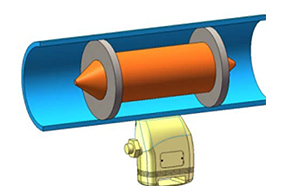

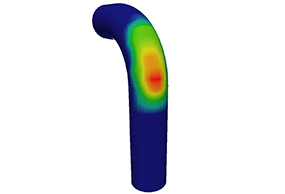

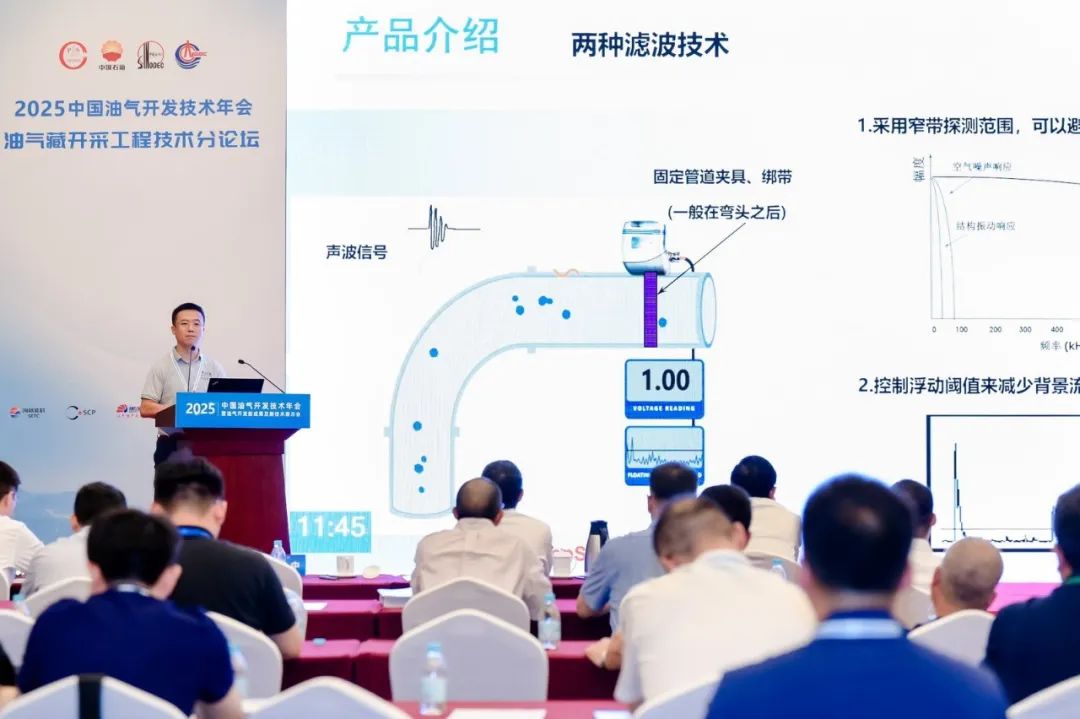

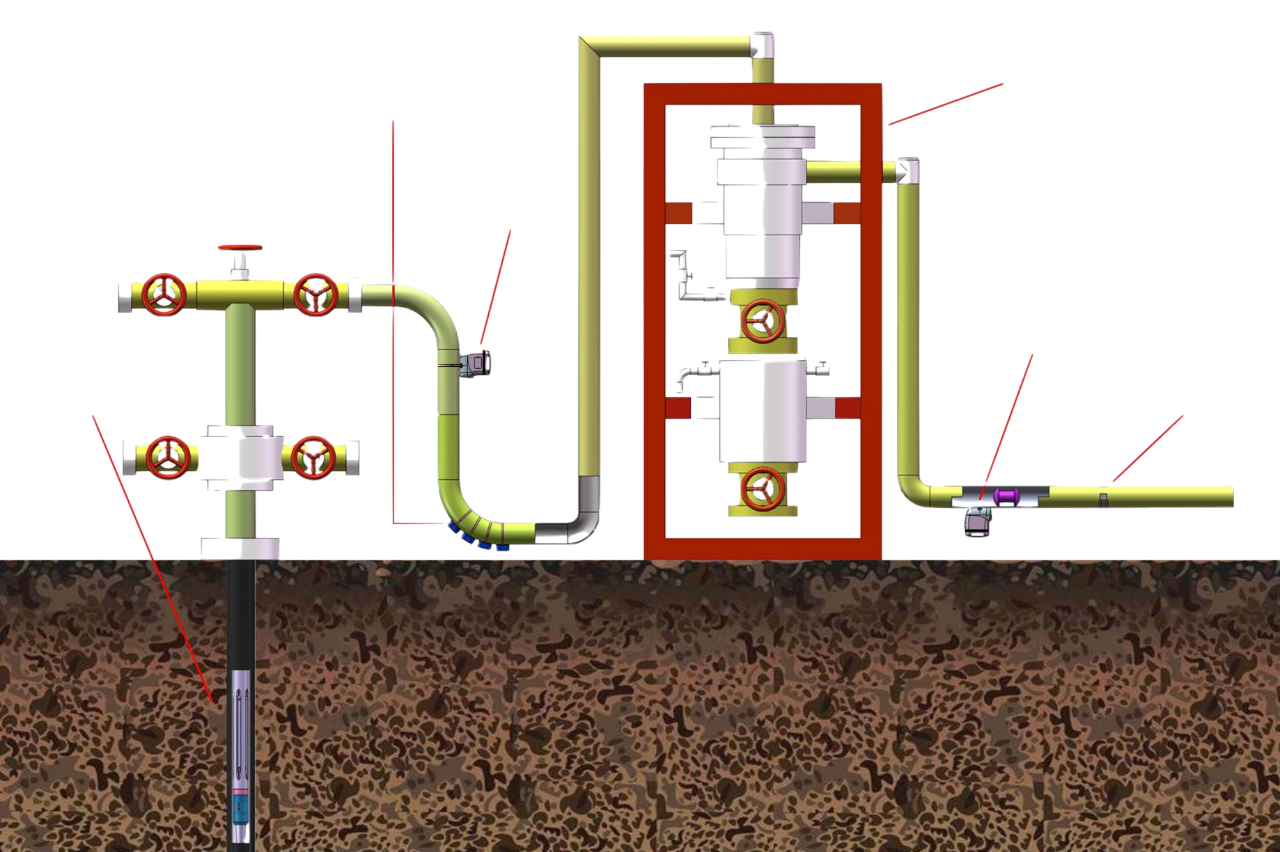

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p

When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP).

The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP). The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion.

The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion. Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials.

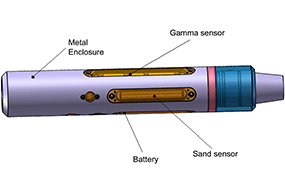

Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials. The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc

The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

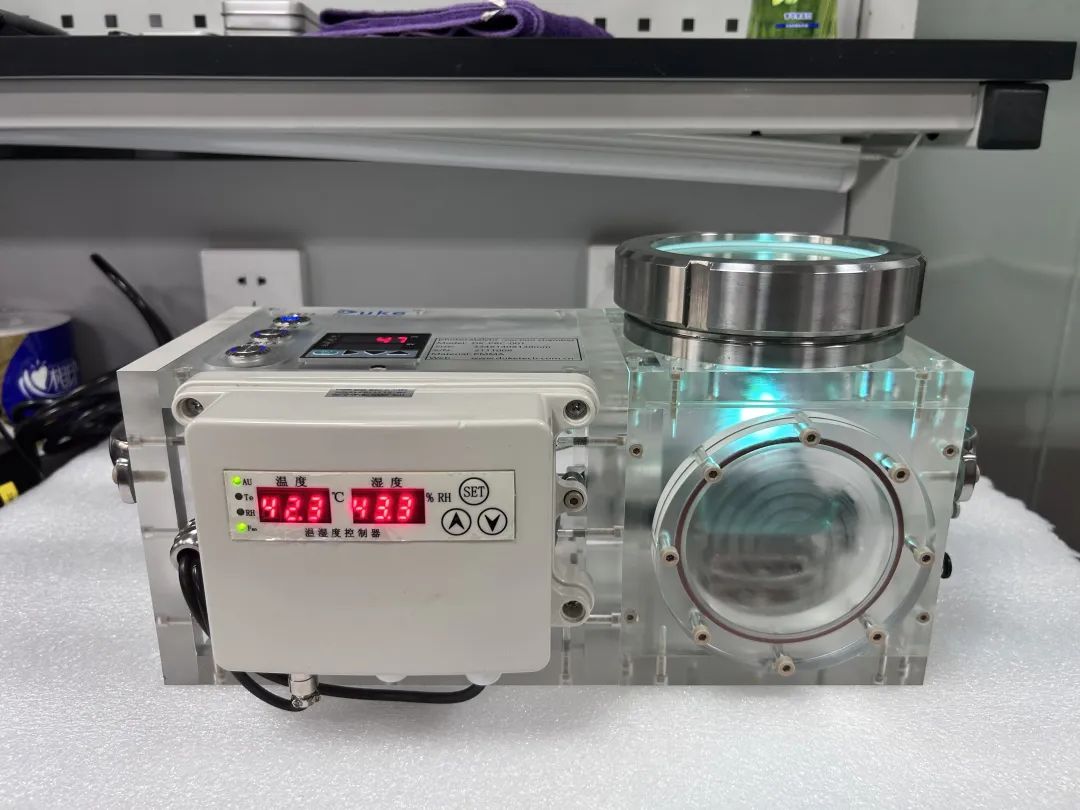

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring The Duke photoacoustic spectroscopy greenhouse gas analyzer

The Duke photoacoustic spectroscopy greenhouse gas analyzer

An All-Round Tool for Catalytic Research

An All-Round Tool for Catalytic Research Infrared Photoacoustic Spectroscopy Gas Analyser

Infrared Photoacoustic Spectroscopy Gas Analyser