Orion 3100S air molecular pollutant monitoring system

Ultra-sensitive, Real-time Measurement of Trace Ammonia , HCl , HF Gas in Clean Room in Lithography Process

The Deep Ultraviolet (DUV) lithography process has proven to be especially sensitive to many types of molecular level contaminates. Ammonia, and acid gases are known to create problems throughout the fab.

The development of improved DUV Resist materials and long-life filters has not lessened the need for continuous real-time monitors, in fact it has made the measurement of airborne contaminants critically important.

The use of the ORION 3100 based on CEAS Series Analyzer will improve resist uniformity, guarantee maximum filter life, and reduce process downtime.

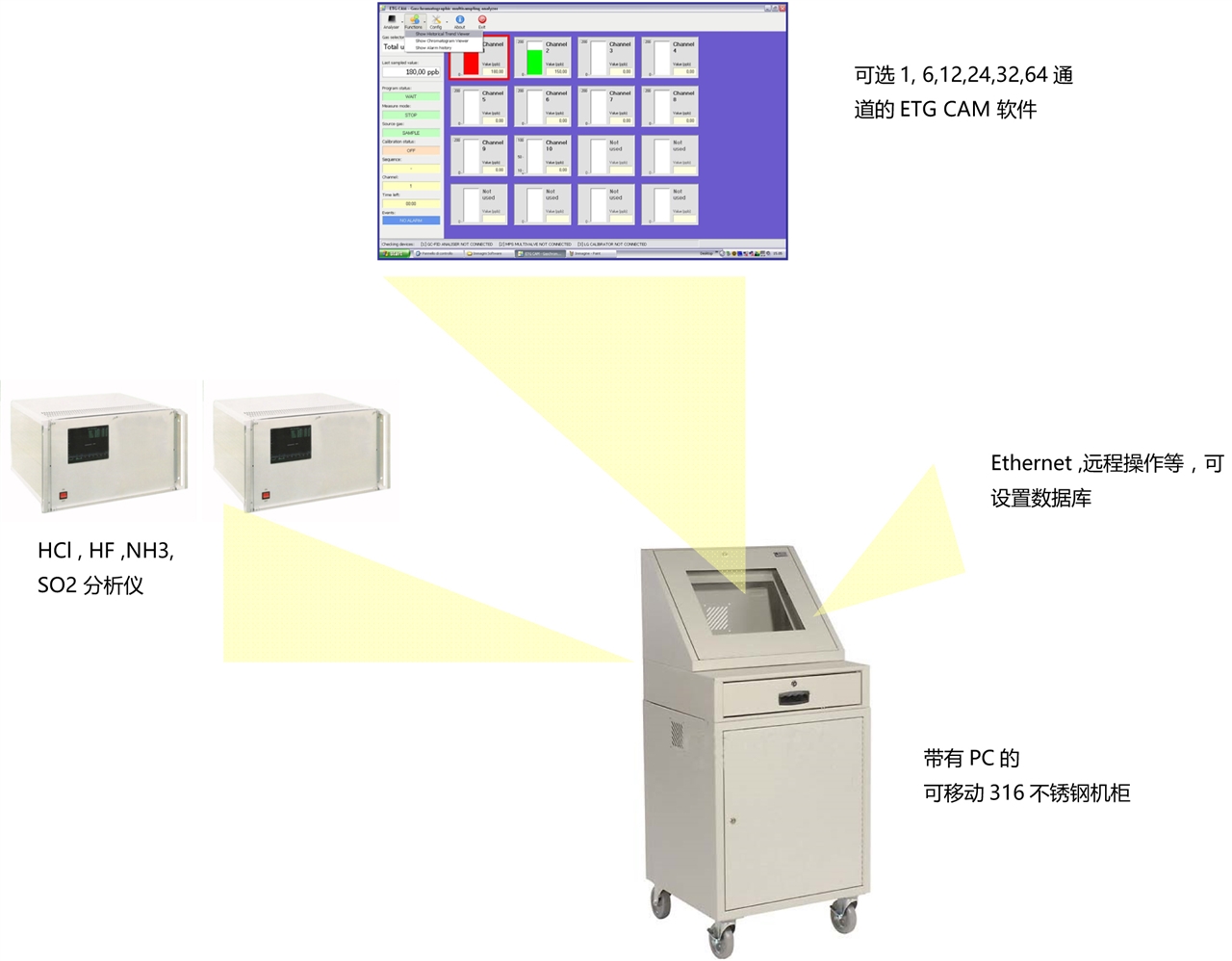

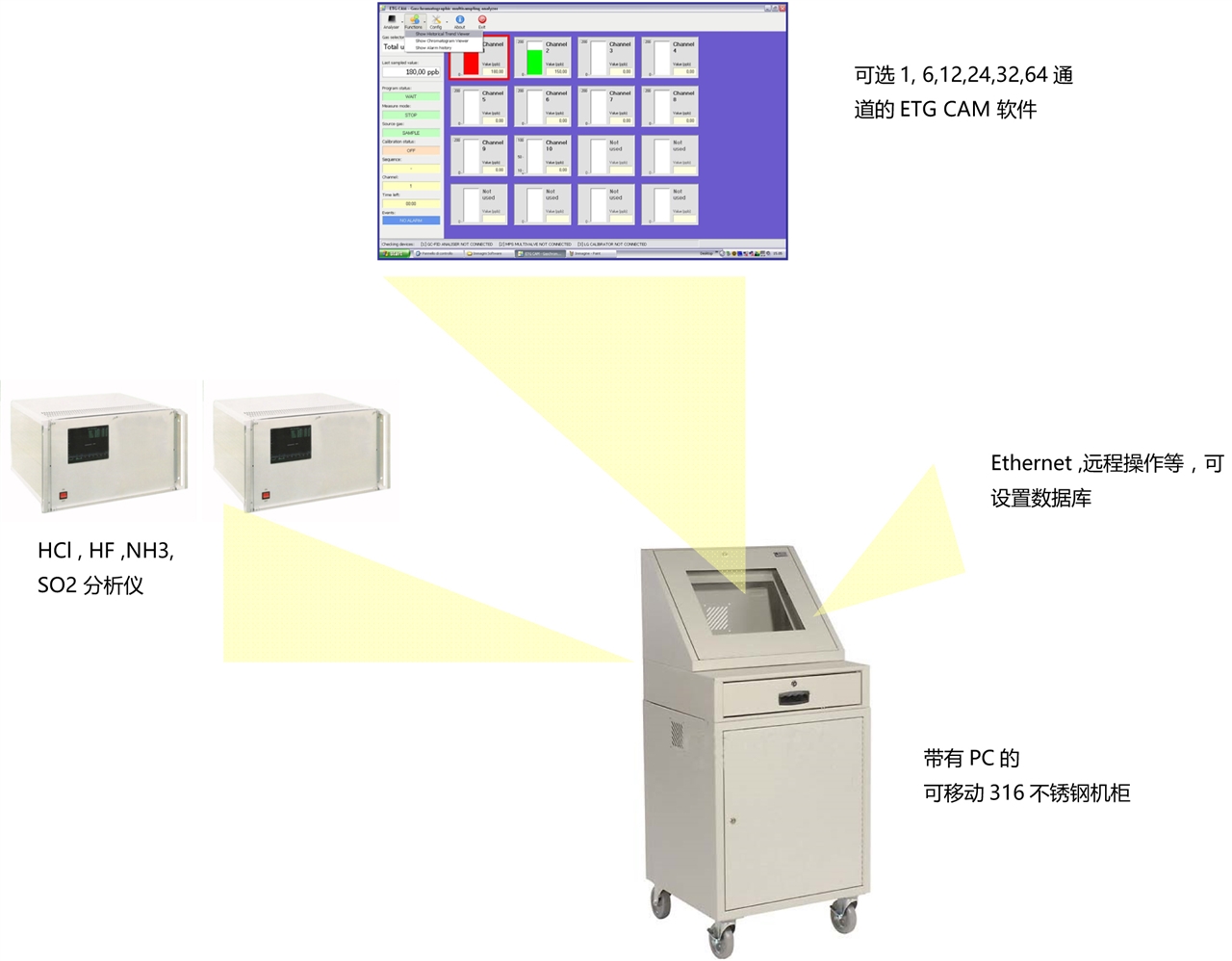

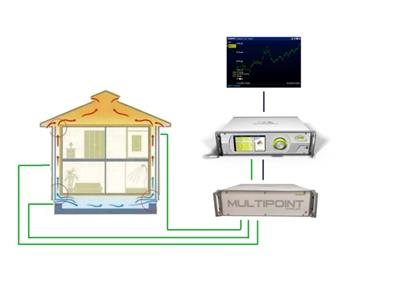

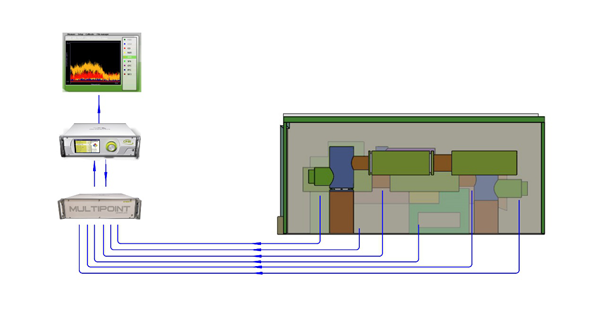

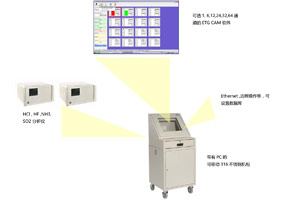

ETG HMI (Human Machine Interface) software allows real-time viewing, manipulation, and automation of ammonia, HCl, HF analyzer that are sampling from several different locations. This software program was written for semiconductor facilities attempting to monitor and control airborne contamination in the DUV lithography process. This software has the flexibility to be applied to any industrial setting where multipoint sampling by one or more CEAS analyzers is needed. Features include easy interactive control of alarms, data logging, historical trending, and basic analyzer functions from a Windows environment.

Enhanced Sensitivity

The instrument, based on CEAS technology, is extremely simple to use, inexpensive to operate, and includes all components (internal vacuum pump, keyboard, mouse, video monitor) to start recording data within minutes. Other atmospheric gases, including water vapor, carbon dioxide, oxygen, and methane, do not interfere with the HCl, HF, NH3 measurements. The instrument includes an internal computer that can store data practically indefinitely on its internal hard drive (for unattended long-term operation), and that can send real-time data to a data logger through its analog and digital (RS232 serial) outputs. In addition, an Ethernet connection allows remote access to data files stored on the instrument’s hard drive. ETG HCl Analyzer provides the high quality data necessary for the most demanding trace gas monitoring applications.

Detectivity/Precision (1-σ) is : HCl 0.1 ppb ; HF 0.1 ppb ; NH3 < 0.1 ppb

Fast time of response

The data it's updated every 5 seconds for each channel .

System Plug & Play

The system it's very simple to use and in few minutes he can to operate in clean room.

Low cost of ownership

The cost of ownership are very limited because the CEAS don't need of special consummables or critical parts

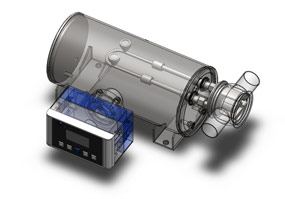

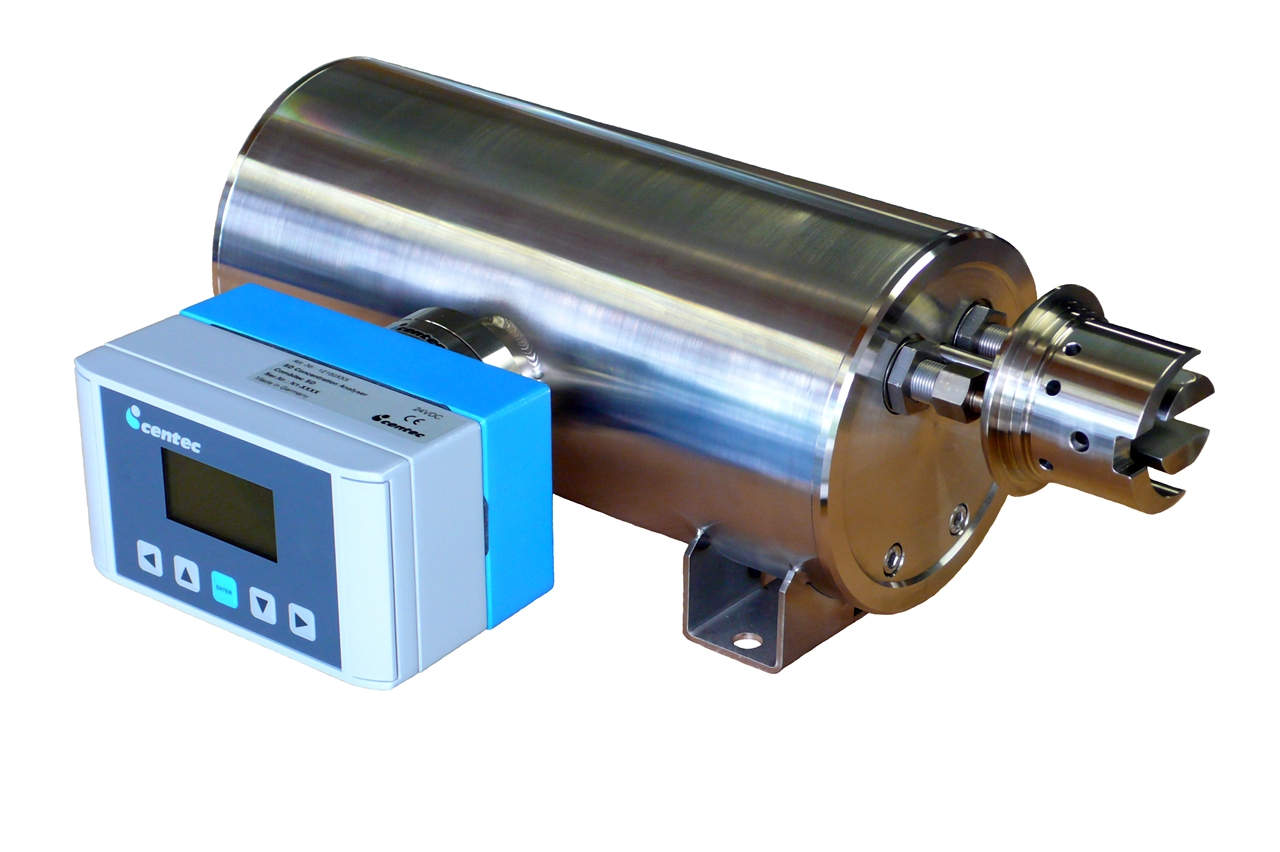

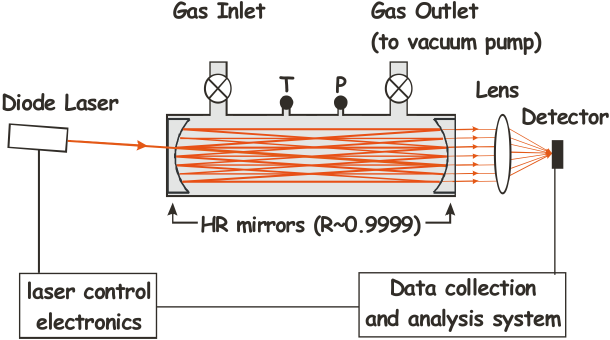

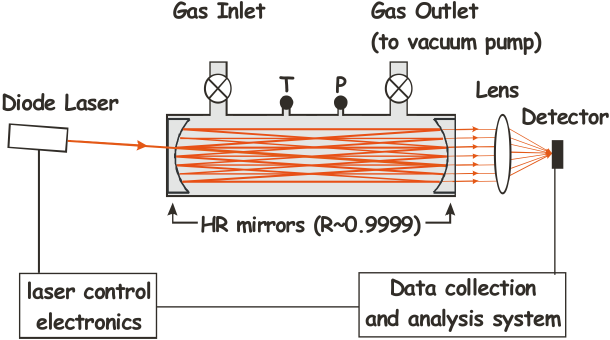

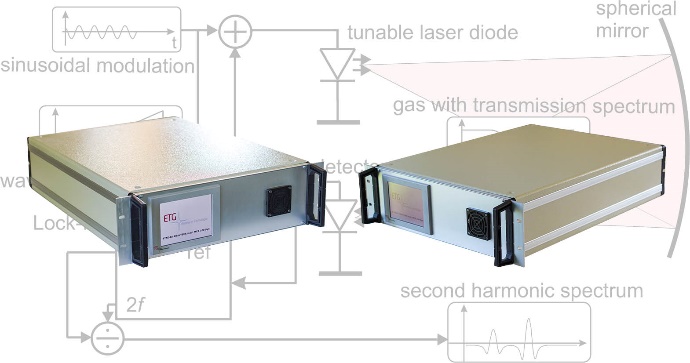

CEAS – Theory of operation

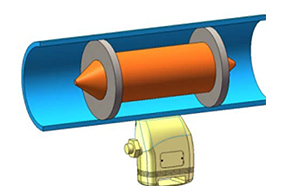

Schematic diagram of the instrument based on CEAS for high-sensitivity absorption measurements in the near-infrared region. The measurement cell is comprised of a cylindrical tube sealed by a pair of highreflectivity mirrors. The relative laser wavelength is measured by recording the laser transmission through a solid (FSR = 2.00 GHz) etalon. The beamspropagating out of the cell through the left-side cavity mirror have been omitted for clarity.

The EP version incorporates proprietary internal thermal control for ultra-stable measurements with unsurpassed precision, accuracy and drift.

The CEAS technology has many proven advantages over conventional first-generation cavity ringdown spectroscopy (CRDS) techniques. In brief, since the laser beam does not have to be resonantly coupled to the measurement cell (i.e. precise beam alignment is not critical), ETG Analyzers are relatively inexpensive, simple to build, and inherently robust thermally and mechanically.

Key Features of ORION 3100

· Real-time at sub-ppb measurements

·

CEAS principle of operations

· Continuous, unattended operation in harsh or hazardous environments

· No reagents, radioactive source, paper tape, absorbent tubes or other expensive consumables required for operation

· Long-term stability and reliability

· Solid-state electronics and no moving parts

· Low maintenance for maximum uptime

· Every monitor is shipped factory-calibrated with an applications performance specification.

· CEAS analyzers for single/multiple trace gas compounds detection

· Multipoint sampling from 4 to 64 channels

· Programmable Alarm and Fault Relays with Individual Programmable Alarm Levels

· Programmable Sample Point Sequencing with Individual Channel Purge and Analysis

· Open Communication Protocol for easy integration to existing systems

· No Data loss during power interruption or shutdown

· Touch-screen display allows Graphic and Operator functions to be changed or updated easily

· Connections ¼ “ OD

· Piping : PFA, PVDF

· Max length pipe line for each channel measured : 80 mt

· Panel PC colour VGA touch screen which allow graphic and operator functions

· Remote visualization and operation by Radmin Software or similar

· Any carrier or special utilities

· Output signal : Standard : RS232 , Ethernet Optional : 4-20 mA, Modbus

· Electrical supply : 115-230 Vac 50/60 Hz

· Calibration verification by optional Calibration with Permeation generator

· Sampling by Sample & Fast loop pump

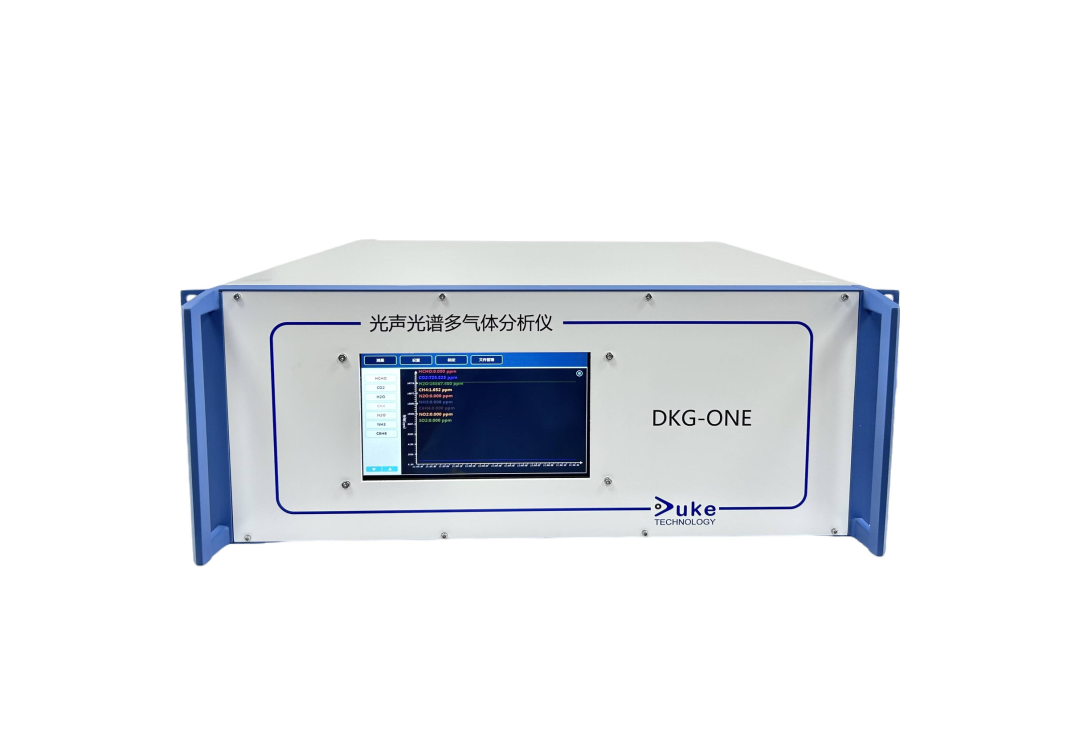

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system.

Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system. DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs

DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency.

Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency. SF6 is widely used in GIS as a good insulation and interruption gas.

SF6 is widely used in GIS as a good insulation and interruption gas.

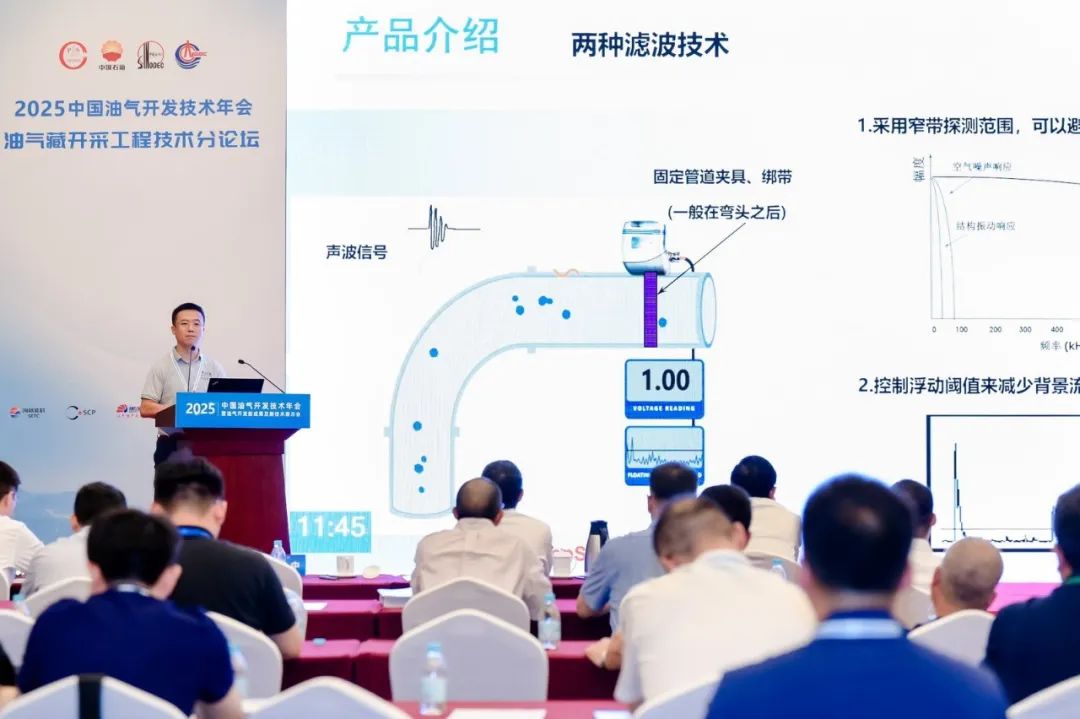

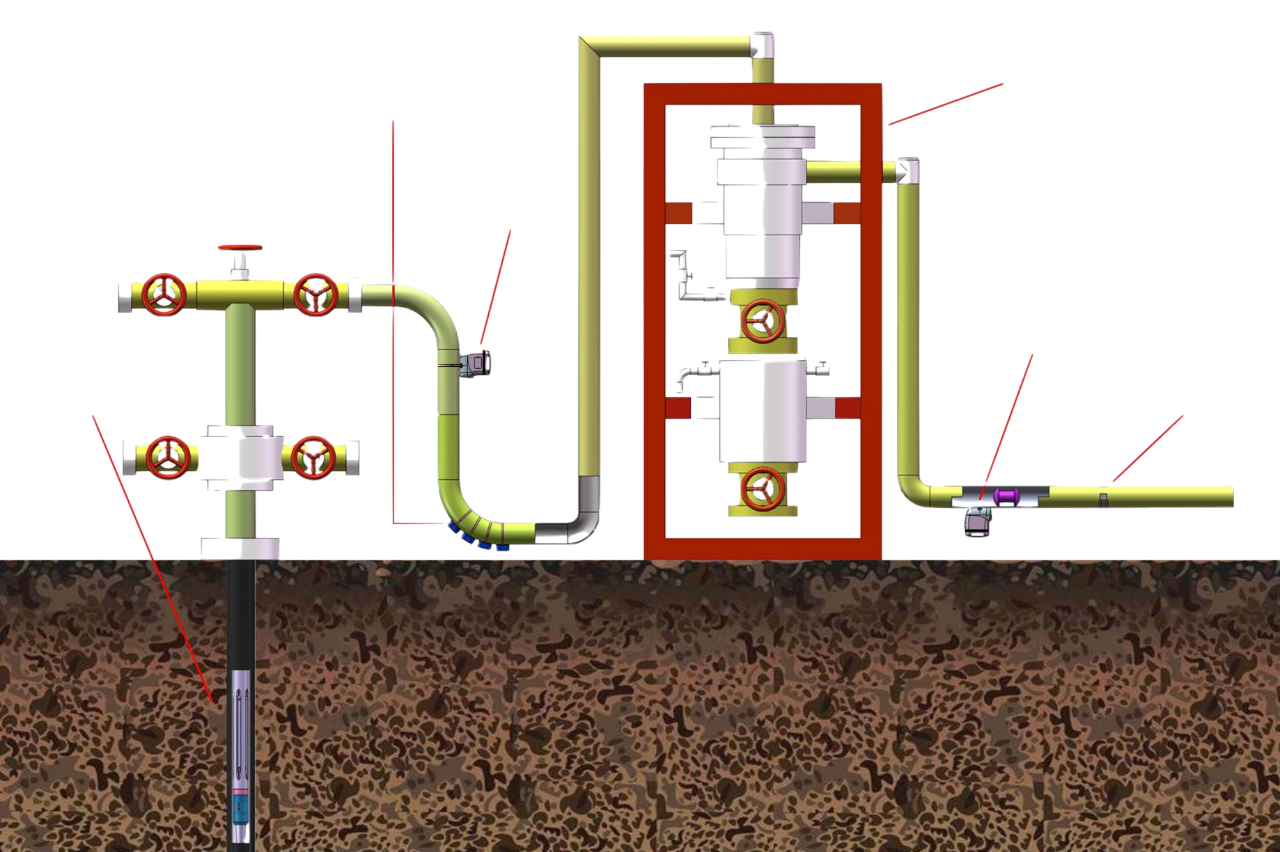

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

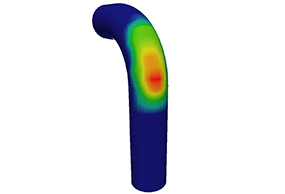

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p

When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP).

The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP). The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion.

The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion. Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials.

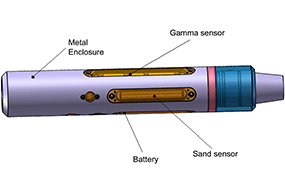

Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials. The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc

The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

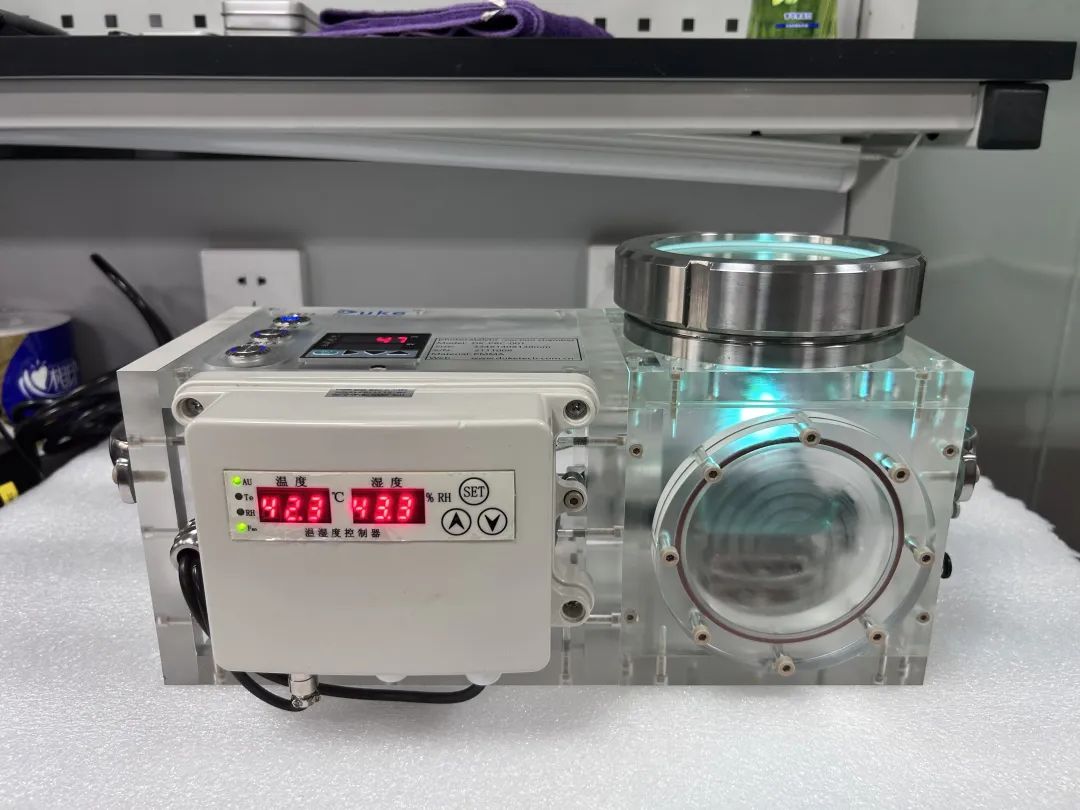

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring The Duke photoacoustic spectroscopy greenhouse gas analyzer

The Duke photoacoustic spectroscopy greenhouse gas analyzer

An All-Round Tool for Catalytic Research

An All-Round Tool for Catalytic Research Infrared Photoacoustic Spectroscopy Gas Analyser

Infrared Photoacoustic Spectroscopy Gas Analyser