ETG 6900 a Complete Line of Gas analyzer Tunable Diode Laser based for Detection of NH3 – CH4 – HCl – CO2

SOME APPLICATION MODEL AVAILABLE

√ CH4 Landfill Monitoring ETG 6901 A – CH4 ambient monitor

√ Biogas Detection ETG 6902 A - CO2 ambient monitor

√ Continuous Emission Monitoring ETG 6903 A - NH3 ambient monitor

√ Fugitive Emissions ETG 6903 H - NH3 Hot wet gas monitor

√ Natural Gas Detection ETG 6904 H - HCl Hot wet gas monitor

√ Agriculture ETG 6900 X - CH4/NH3 and CO2 (NDIR) and O2 (ECD)

√ Industrial Process Control

√ Selective Catalytic Reduction SCR/DeNOx

√ Climate Change Research

√ Environmental Research

√ Breath Analysis

THE ADVANTAGES

· Extremely high selectivity to the target gas

· Functional safety, continuous status reporting

· Long lifetime (10+ years)

· Fast response times

· Low power consumption possible

· Very low cost-of-ownership (no regular replacement and/or calibration)

· Low cost of the gas sensor through excellent scaling costs of the components

· 19”inch Rack Mounting

· User Friendly interface

· Data logging

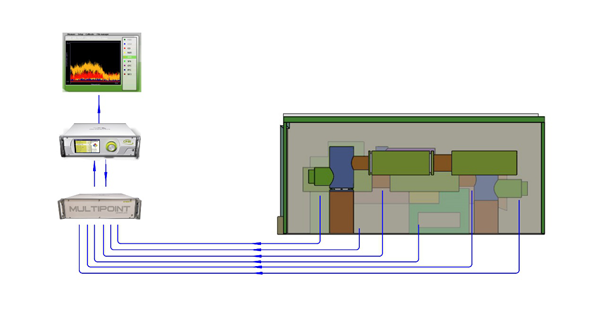

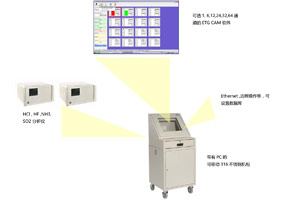

· Expandable in a multipoint system

· Zero & Span Calibration

· Status sensor verification

THE TECHNOLOGY

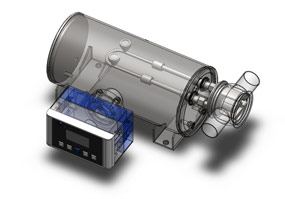

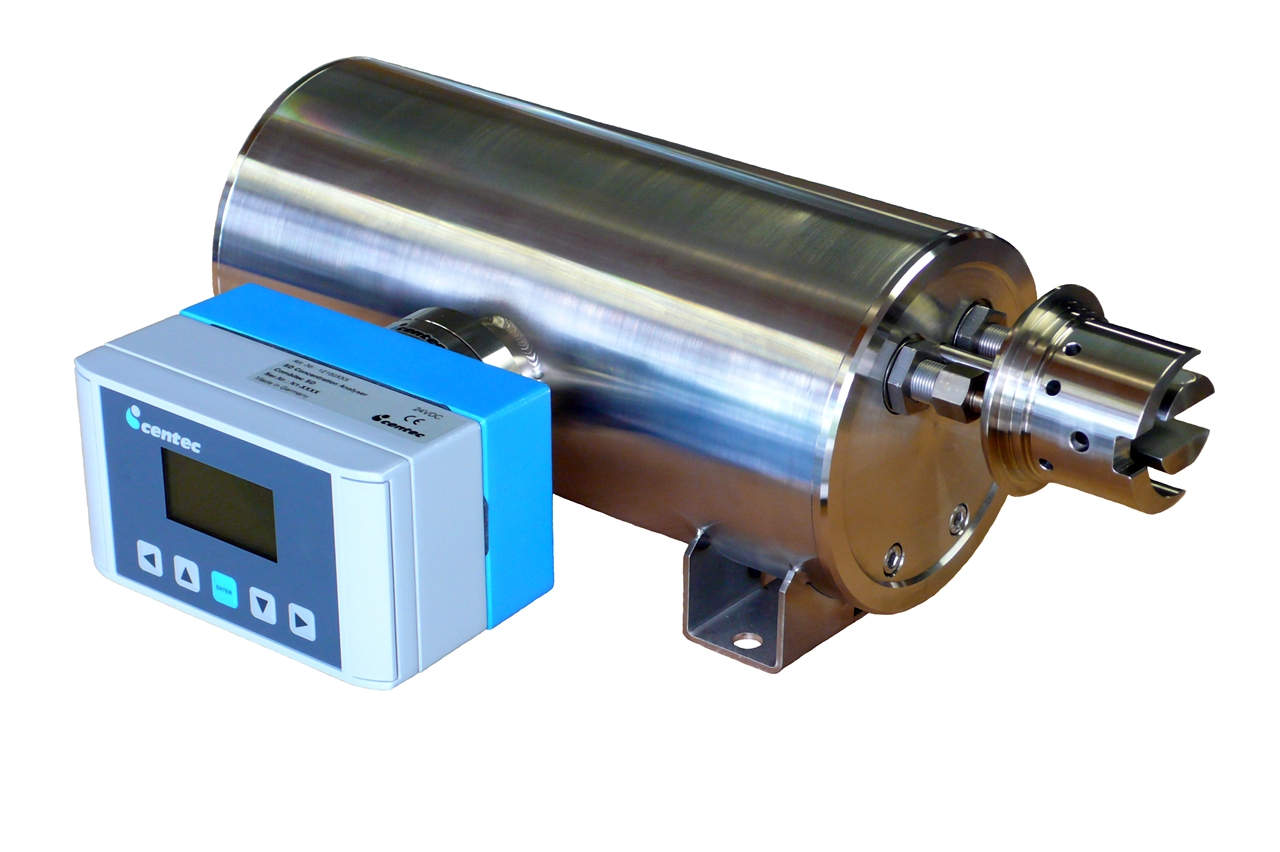

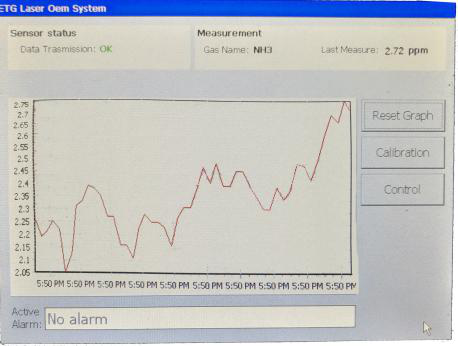

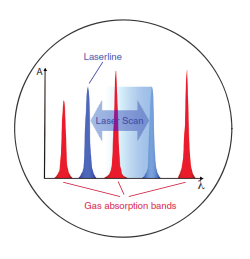

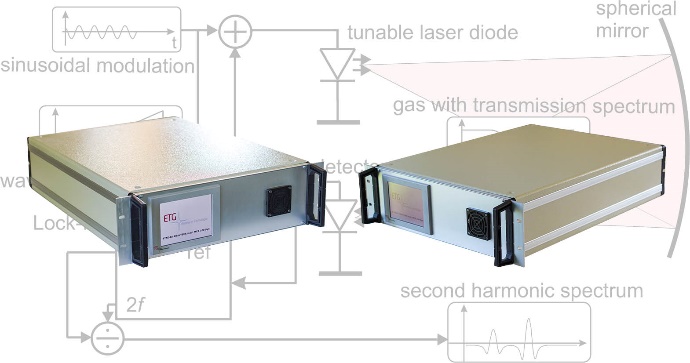

ETG uses technology-enhanced TDLS for gas detection, where a 0.1 nm narrow bandwidth diode laser beam scans across an absorption band of the target gas, performing a high-resolution near-infrared absorption measurement. Electronic lock-in technology allows separating the gas absorption information from electro-optical system information, leading to a detection method eliminating the need for a physical reference channel and offering continuous sensor status monitoring. Thus, ETG TDL 6900 series present a clear alternative to current sub-optimal detection solutions and combine precise, contact-less optical measurements with high target gas selectivity, calibration-free operation, low cost-of-ownership and easy operation.

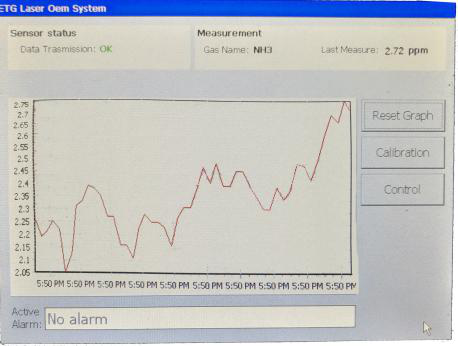

The ETG 6900 series are ready-to-use devices for the measurement of gases such as NH3, HCl, CH4, CO2, (H2O). These lines of instrument are ready to use in the field of gas detection and monitoring in diverse industries. The high sensitivity and large dynamic range of the Tunable Diode Laser Spectrometry (TDLS) detection technology enables measurement from sub-ppm level to high percentage concentration without physical adaptation of the device.

SPECIFICATIONS

Target Gas Lower Detection Limit Typical Measuring Range

NH3, (H2O) Ammonia ***

(Hot-wet measurement) 0.8 ppm 0 – 20, 50, 100, (500) ppm

HCl, (H2O) Hydrogen chloride ***

(Hot-wet measurement) 0.8 ppm 0 – 50, 100, (500) ppm

NH3 Ammonia 0.4 ppm 0 – 100 (500) ppm

CH4 Methane 0.4 ppm 0 – 100 (40'000) ppm

CO2 Carbon Dioxide 4.0 ppm 0 – 1000 (300’000) ppm

* Other gases on request. ** Detection limits at constant system temperature, 20°C, 1013 hPa and 50 ± 1.5 % r.H. Detection limits may change where system temperature changes occur significantly faster than concentration changes, and/or where a difficult gas matrix is present. *** Detection limits degrade at higher temperatures due to spectroscopic reasons; e.g. NH3 at 190°C.

Accuracy ± 2% full scale reading depending on integration stability (temperature & pressure)

Precision gas dependent

Zero drift over 2 h period - within accuracy

Span drift over 8 h period - within accuracy

Max. error on temp. comp. % of < 0.1 reading/°C

Linearity & Repeatability included in the accuracy

Cross talk/interference Gas matrix and application dependent

Displayed resolution ppm 0.1 (negative values can also be displayed)

Refresh rate s 1 (integration time can be selected, max. 120 s) up to 2 s in case no target gas is present

T90 time s 2 (at gas flow rate of 3 L/min)

Ambient temp. compensat. °C -10 … 65 (as narrow as possible, application defined)

Meas. gas max. humidity % abs. H2O application dependent, needs calibration Input for external parameter compensation pressure, temperature or matrix gas concentration (optional customization)

Maximum measurement mL / min 5’000 (1’000); std. calibration carried out at 3’000 gas flow (Minimum)

Electrical supply Vac 220-230/115 50/60 Hz

Enclosure 19”Rack HE 4 ( depth 500 mm)

Pneumatic connections Swagelok 6 mm O.D.

Sample pump Internal

Analog Outputs 4-20 mA (not isolated)

Ports Ethernet

Monitor 5.7”Resistive Touch Screen

Data logging by USB port

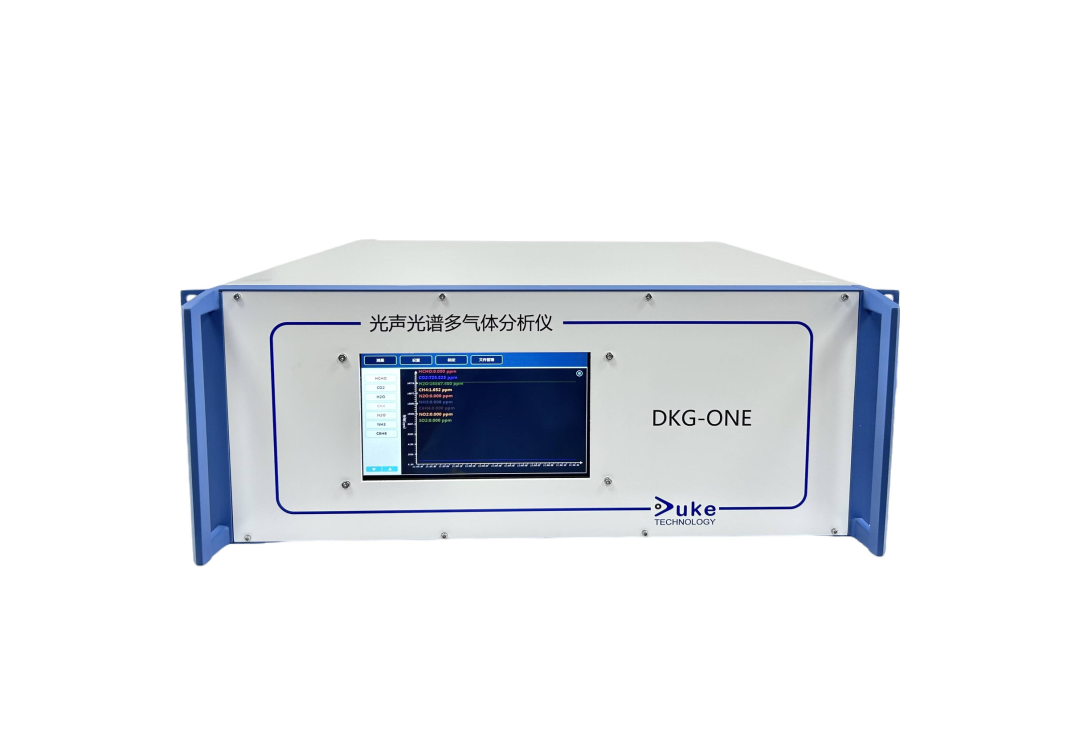

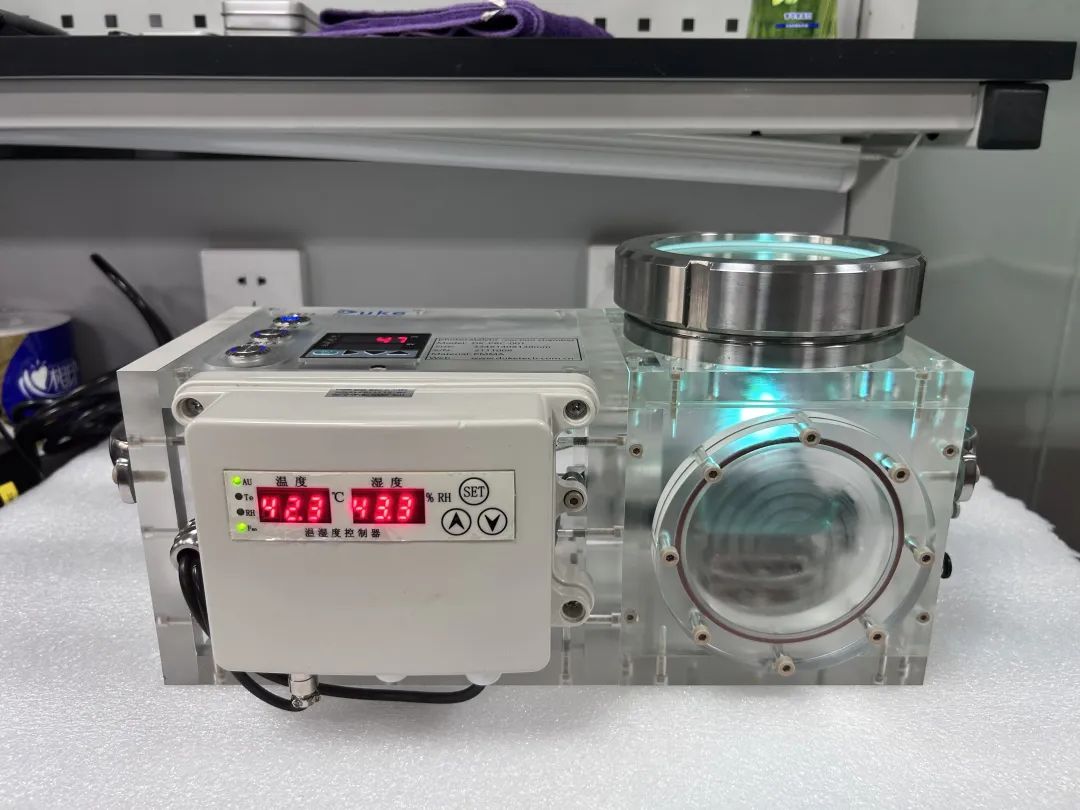

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system.

Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system. DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs

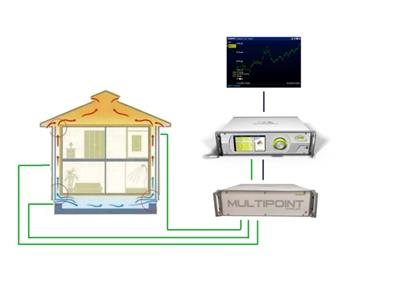

DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency.

Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency. SF6 is widely used in GIS as a good insulation and interruption gas.

SF6 is widely used in GIS as a good insulation and interruption gas.

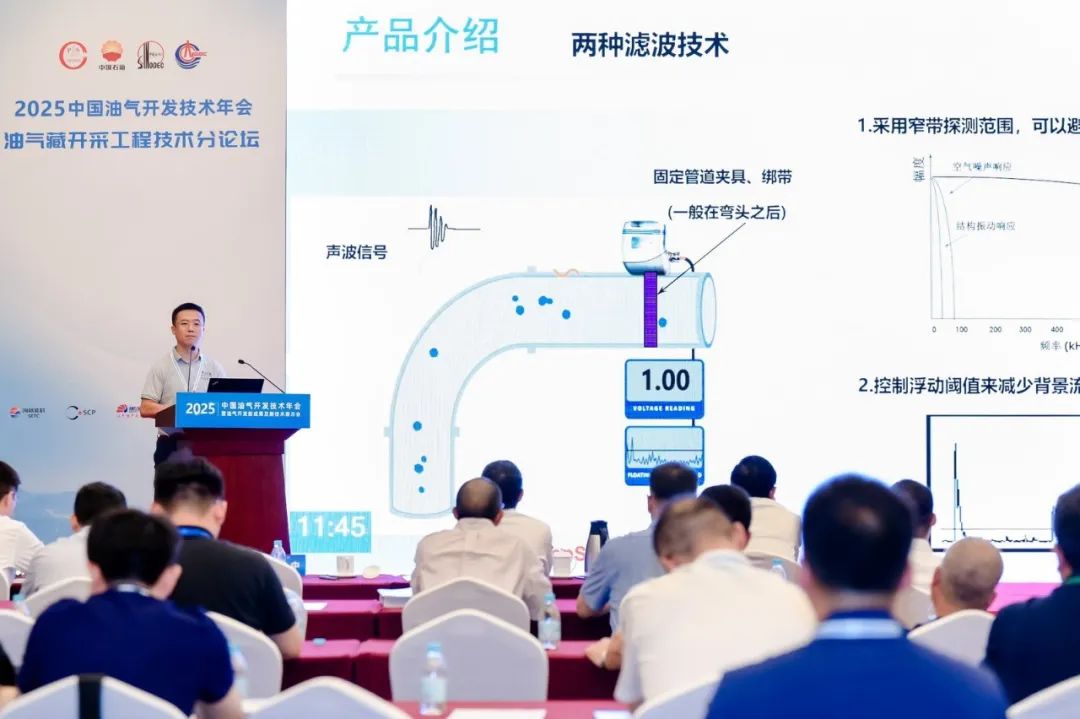

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

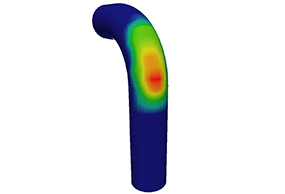

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p

When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP).

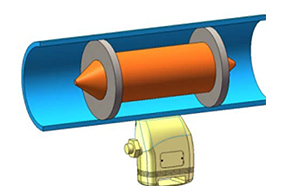

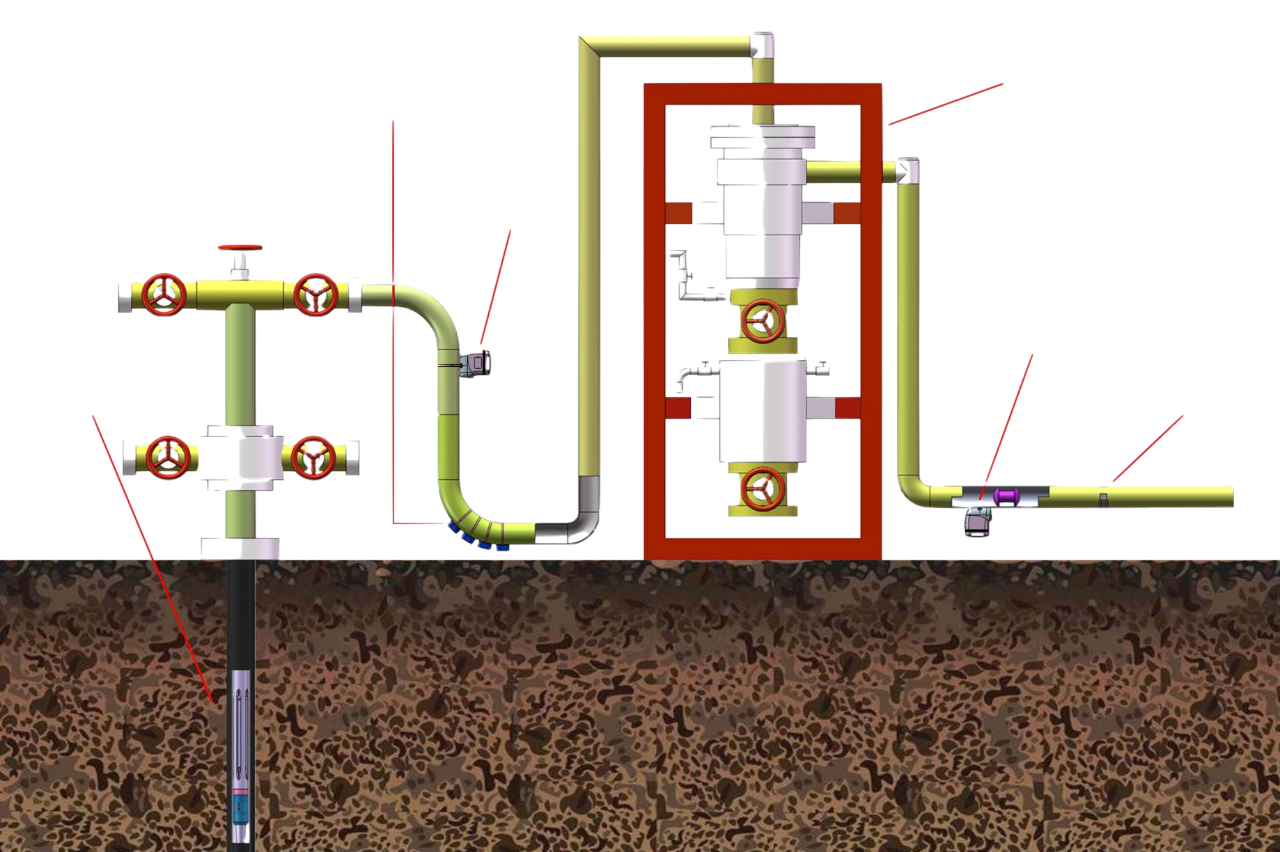

The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP). The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion.

The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion. Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials.

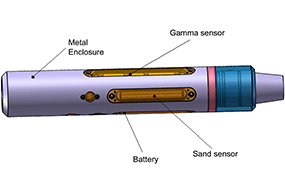

Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials. The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc

The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring The Duke photoacoustic spectroscopy greenhouse gas analyzer

The Duke photoacoustic spectroscopy greenhouse gas analyzer

An All-Round Tool for Catalytic Research

An All-Round Tool for Catalytic Research Infrared Photoacoustic Spectroscopy Gas Analyser

Infrared Photoacoustic Spectroscopy Gas Analyser