F10 photoacoustic spectroscopy Multi-Gas Analyzer

F10 Concept

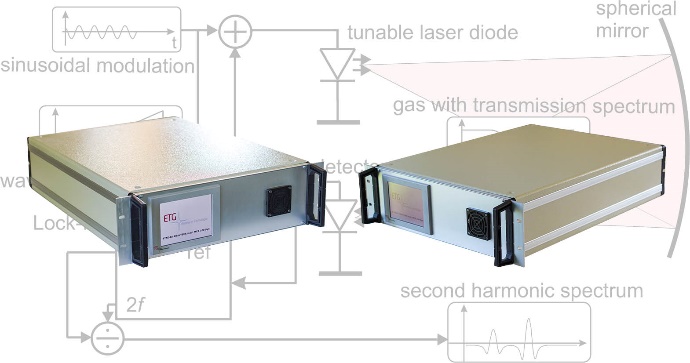

The F10 is based on photoacoustic infrared technology. It has pulsed IR source and 10 distinct spectral bands in the mid-IR region defined by narrow band-pass optical filters. High sensitivity is obtained by utilizing the patented cantilever based optical microphone technology.

Multi-component analysis High selectivity is achieved by choosing up to 10 optical filters with narrow spectral bands for target gases as well as interfering gases. Several spectral regions can be used with each gas for minimal cross-sensitivity. Analysis is based on a modified classical least squares fit of sample response to calibration data.

Photoacoustic technology allows high sensitivity from short optical path length which has been further improved with novel model-based non-linear compensation. This provides linear dynamic range of over five orders of magnitude.

Measurable gases

Hydrocarbons: CH4, C2H6, C2H2, C2H4, etc.

Inorganics: CO2, CO, N2O, SO2, NO, NO2, NH3, NF3, SF6, H2O

VOCs: acetone, ethanol, methanol, benzene, toluene, xylenes, formaldehyde etc.

CFCs and PFCs: CF4, C2F6, R-134a, R 13, etc.

Corrosives (at low levels): HF, HCl, HCN

Anesthetics: isoflurane, sevoflurane, desflurane, enflurane

Features

Up to 9 gases simultaneously

Sub-ppm detection limits

Long calibration period

User-friendly calibration

Built in 2-point sampling

Analysis from very low gas volume

High-resolution graphical display with userfriendly menus

Versatile programming of measurement tasks

Presentation of the measurement results of all gases both numerically and in graphical form Built in trend view for monitoring tasks, no external computer required

No consumables

Applications

Poultry, Swine, Agricultural

Greenhouse gas

Industrial safety and hygiene

Fermentation

Leak detection

Process control

Waste anesthetic gases

Technology

Photoacoustic infrared spectroscopy with cantilever enhanced optical microphone Electronically pulsed IR source

Gold coated gas cell stabilized to 50 °C temperature

Patented ultra-sensitive optical microphone based on a MEMS cantilever sensor coupled with a laser interferometer to measure microscopic movement of the cantilever sensor

19” 3U housing for both table stand and rack mount installation

Built in PC computer with 5,7” color VGA display in the front

User interface of setting the alarm levels for concentrations of gases under monitoring

Data storage capacity of approx. 2 GB. Sufficient for more than a year of continuous monitoring of 9 gases with the shortest sampling interval.

Transfer of measurement results to memory stick via USB or to PC via USB, Ethernet or serial ports.

Four gas connections in the rear. The two sample gas lines, are equipped with filters for dust and small particles.

Compensation of the fluctuations of temperature and pressure within the operational conditions

Cross-compensation of known interferents of the sample gas including water vapor

Environment

Operational conditions:

Temperature range: 0 °C – +45 °C

Humidity range: Below 90% RH, non-condensing

Pressure range: Ambient level

Dust/water resistance: IP20 (IEC 529)

Shock/vibration endurance: Strong vibrations at 33 Hz frequency can affect the detection limit

Storage conditions:

Temperature range: -20 °C – +60 °C

Sample gas conditions:

Temperature: 0 – +49 °C, non-condensing

Pressure: 930 mbar – 1100 mbar

Moisture: Dew point +8 °C or higher

Gas flow: Approx 1 liters/minute

Particulates < 1 μm

General

Dimensions: 48,4 cm W x 13,9 cm H x 40,5 cm D (19,1 in W x 5,5 in H x 16,0 in D)

Weight: Approx. 13 kg

Total internal gas volume: 30 ml

Gas connections:

Push-in connector for 6/4 mm tubing

Electrical connections:

Input voltage: 100 - 240 Vac, 50 - 60 Hz

Input power: 100W

Interface: Ethernet, USB1.2, RS-232, and RS-485

Measurement specifications

Response time: Dependent on the channel integration time (C.I.T.) and the gas exchange period defined. Typically from 30 seconds to few minutes.

Detection limit: Gas dependent. Typically in the subppm region.

Dynamic range: Typically 5 orders of magnitude (i.e. 100 000 times the detection limit)

Zero drift: ± Detection limit per 1 month

Span drift: 3% of measured value per 1 month

Repeatability: 1% of measured value in operational conditions at the calibration concentration Accuracy: Same as the calibration gas accuracy at the calibration concentration. Typically 2-5%.

Temperature stability: Ambient temperature change within the operational temperature range will not cause drift

Pressure stability: Sample gas pressure change within the pressure range will not cause drift

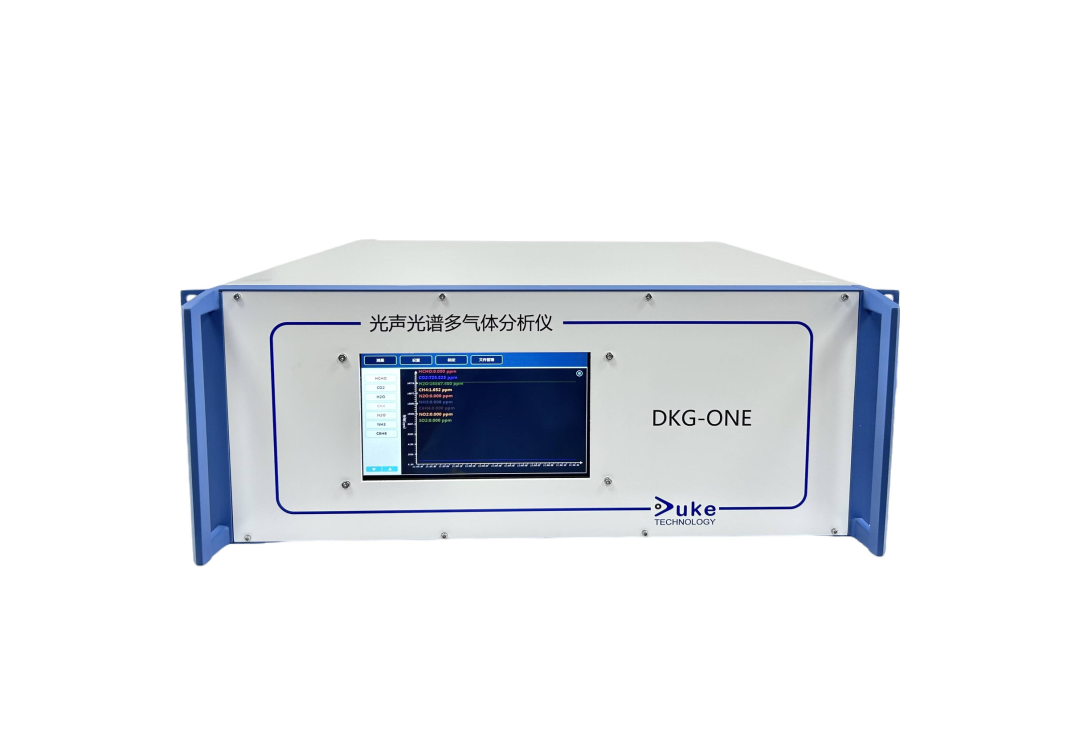

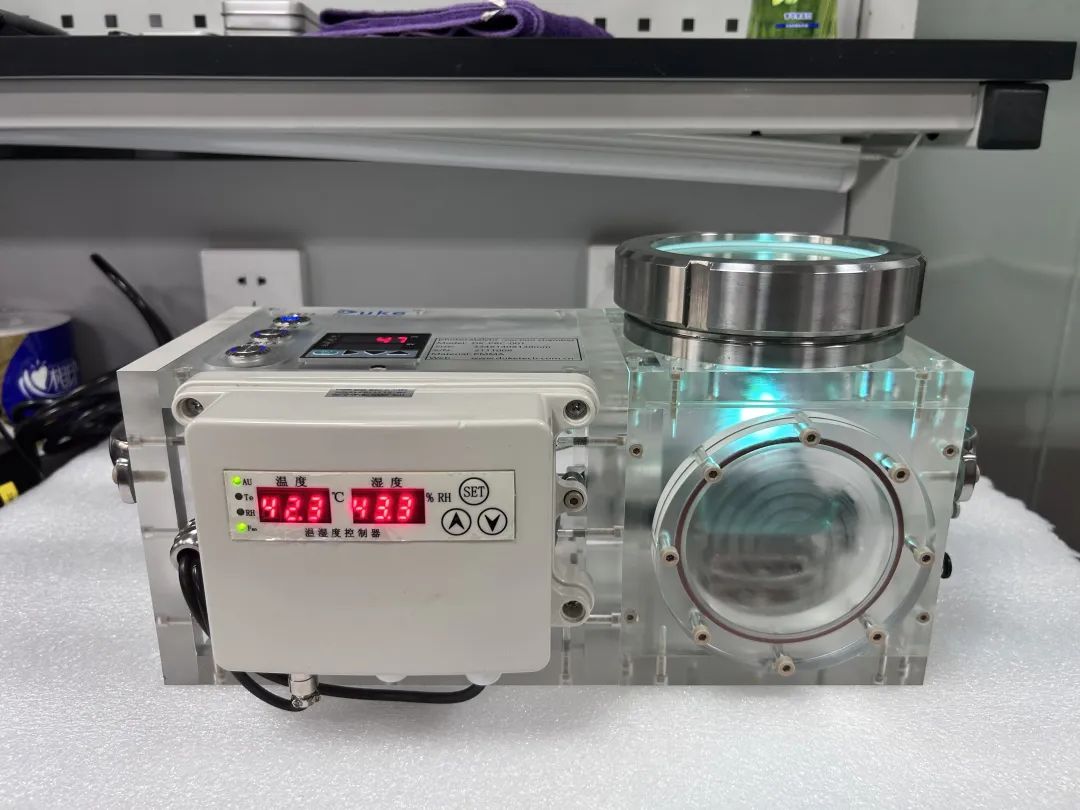

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system.

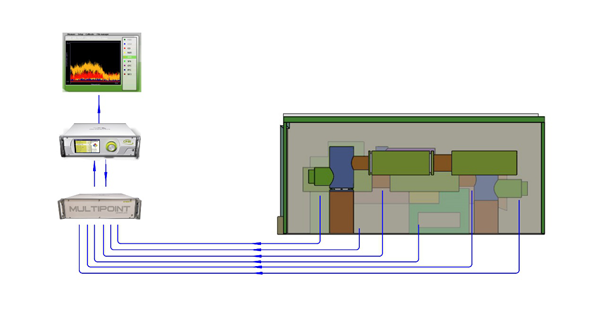

Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system. DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs

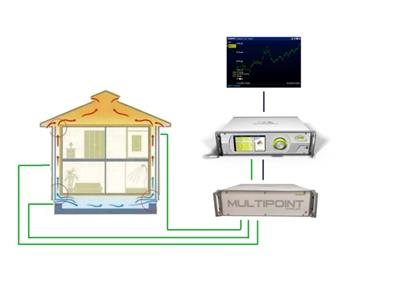

DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency.

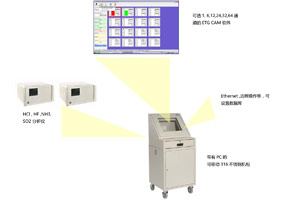

Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency. SF6 is widely used in GIS as a good insulation and interruption gas.

SF6 is widely used in GIS as a good insulation and interruption gas.

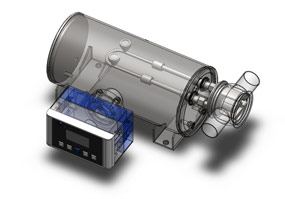

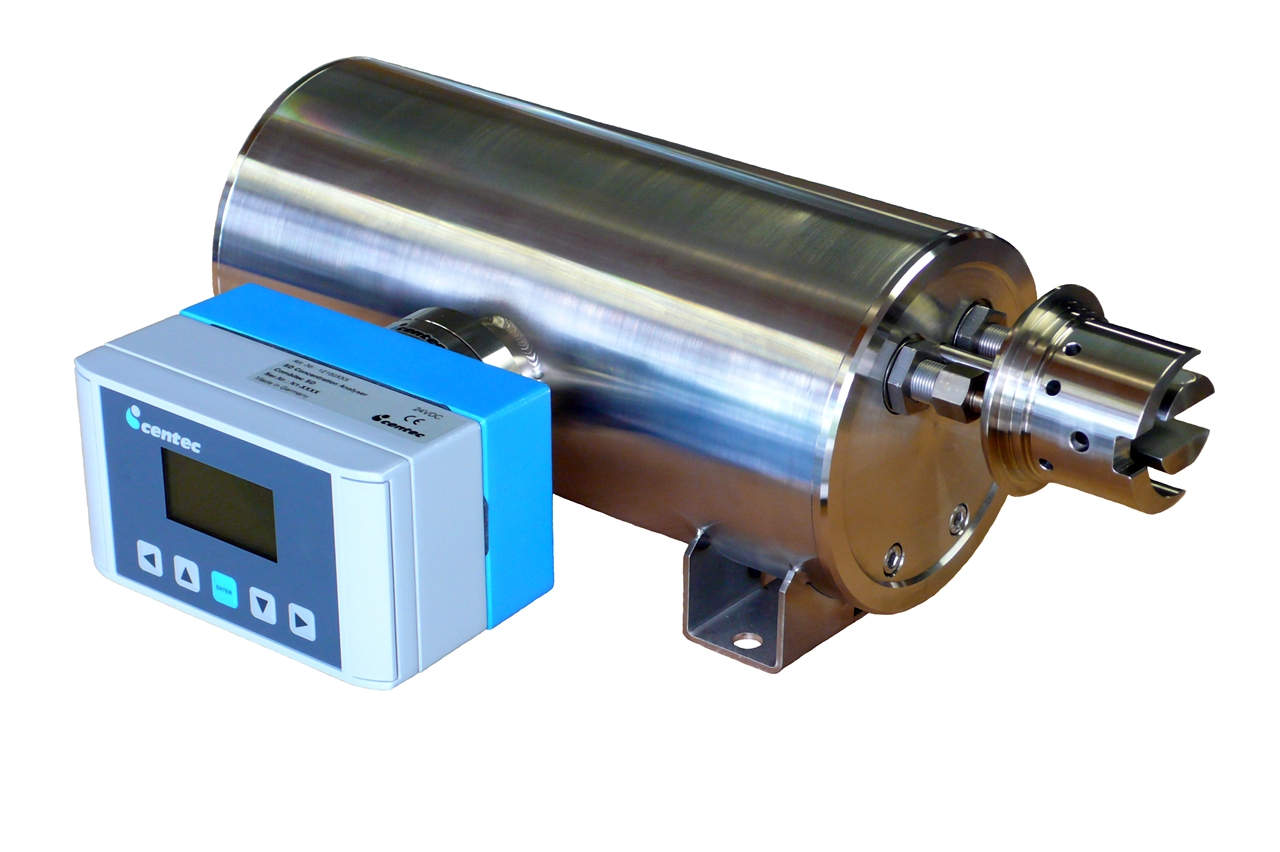

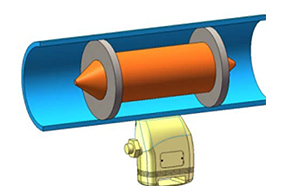

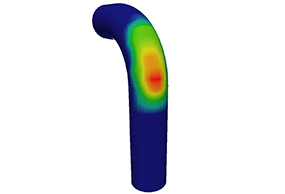

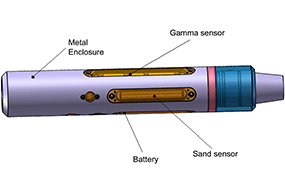

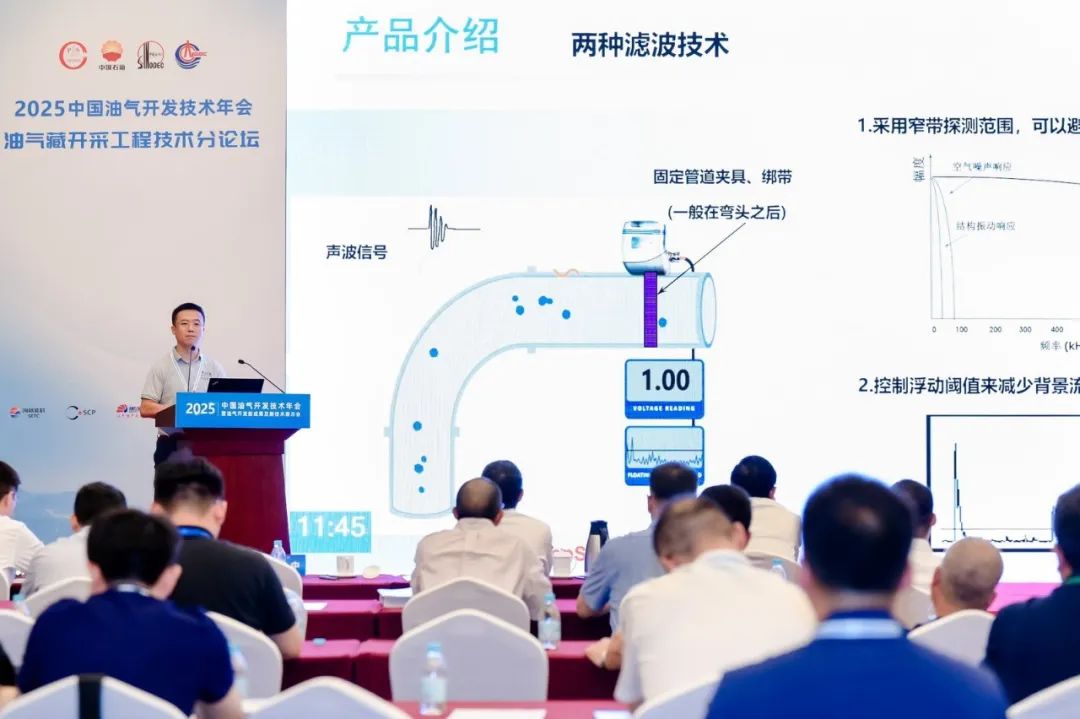

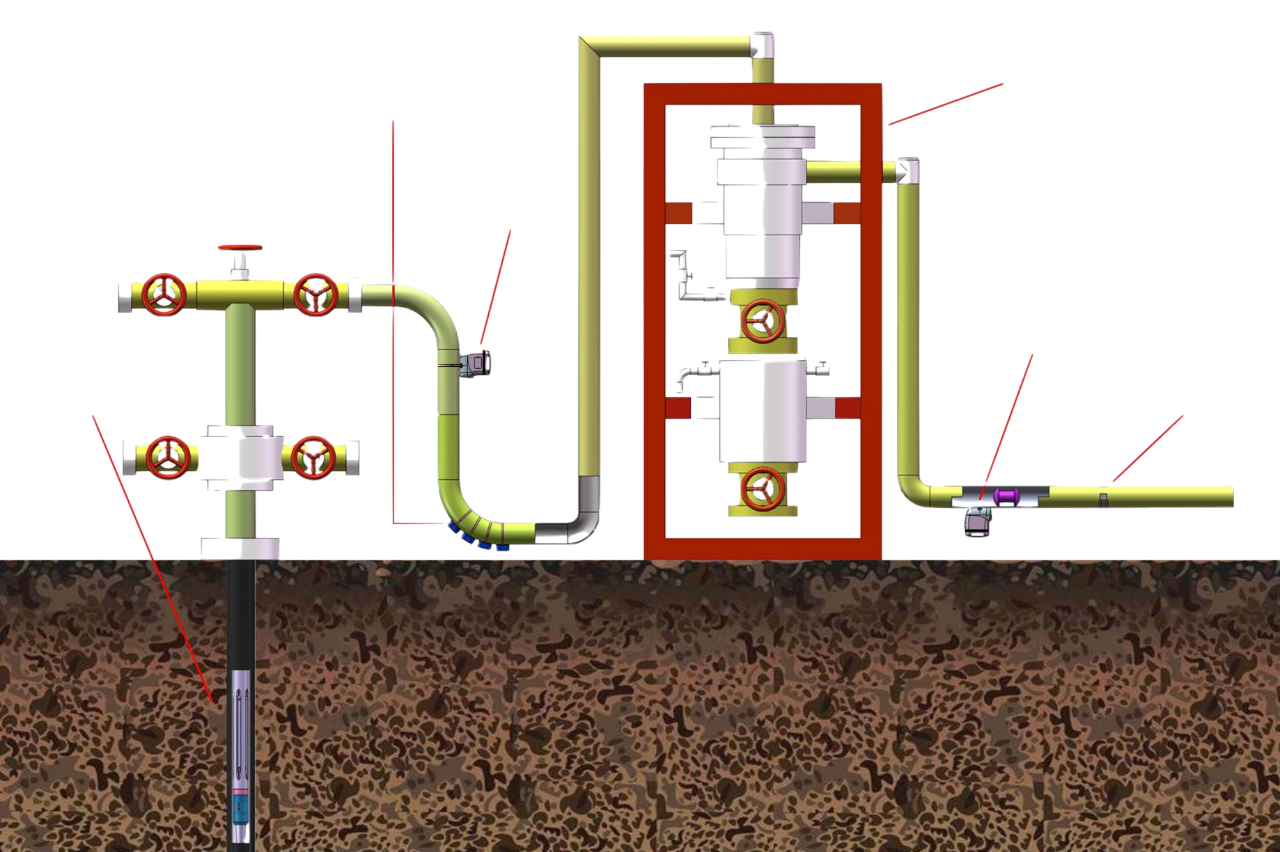

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitoring sys The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p

When sand enters the wells or pipelines during the extraction process, it is essential to ensure the clear passage of the sand. Real-time monitoring of the flow rate, instantaneous flow, cumulative flow, erosion rate, and movement patterns of sand/solid p The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand.

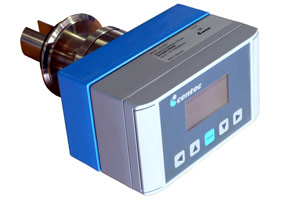

The sand monitoring system from Duke integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP).

The Duke pigging indicator uses passive acoustic (ultrasonic) technology to sense the pig traveling through the pipeline, utilizing a built-in Lock Frequency Digital Signal Processor (LPDSP). The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion.

The DK-SA 830 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion. Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials.

Based on echo sensing technology, the Duke Non-intrusive acoustic pipe thickness monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials. The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc

The innovative DK-SA 850 downhole sand monitoring device features a new tool architecture, integrating advanced sensor design, signal processing technology, and analytical algorithms to accurately detect downhole sand ingress points and assess sand produc DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

DK-SA 860-S Series Vibration Sensor can connect to analog signal output of acceleration, speed, displacement sensors, can calculate speed and displacement data based on acceleration data, features include different sensor parameter settings, data acquisit

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

0.5 ppb detection limit: Utilising an ultra-sensitive patented optical cantilever microphone combined with a quantum cascade laser (QCL) light source, it can detect phosgene concentrations as low as 0.5 ppb, enabling precise identification of even minor l

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring

Duke DK-F10L Photoacoustic Spectroscopy Greenhouse Gas Analyzer: The All-Around Expert for Precise Multi-Gas Monitoring The Duke photoacoustic spectroscopy greenhouse gas analyzer

The Duke photoacoustic spectroscopy greenhouse gas analyzer

An All-Round Tool for Catalytic Research

An All-Round Tool for Catalytic Research Infrared Photoacoustic Spectroscopy Gas Analyser

Infrared Photoacoustic Spectroscopy Gas Analyser