VeGaS

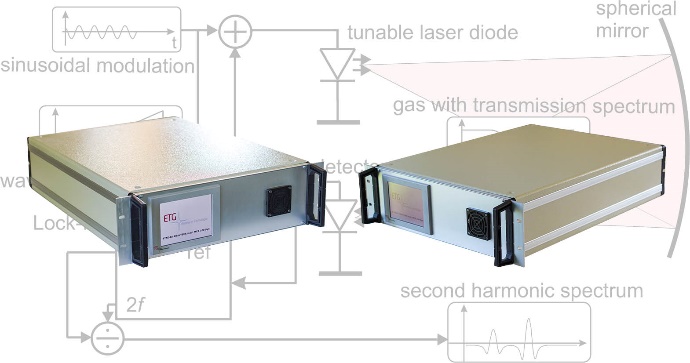

Principle

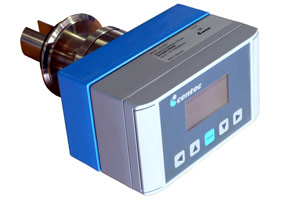

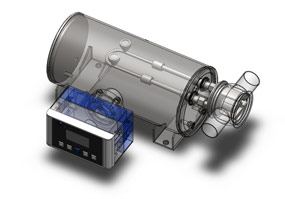

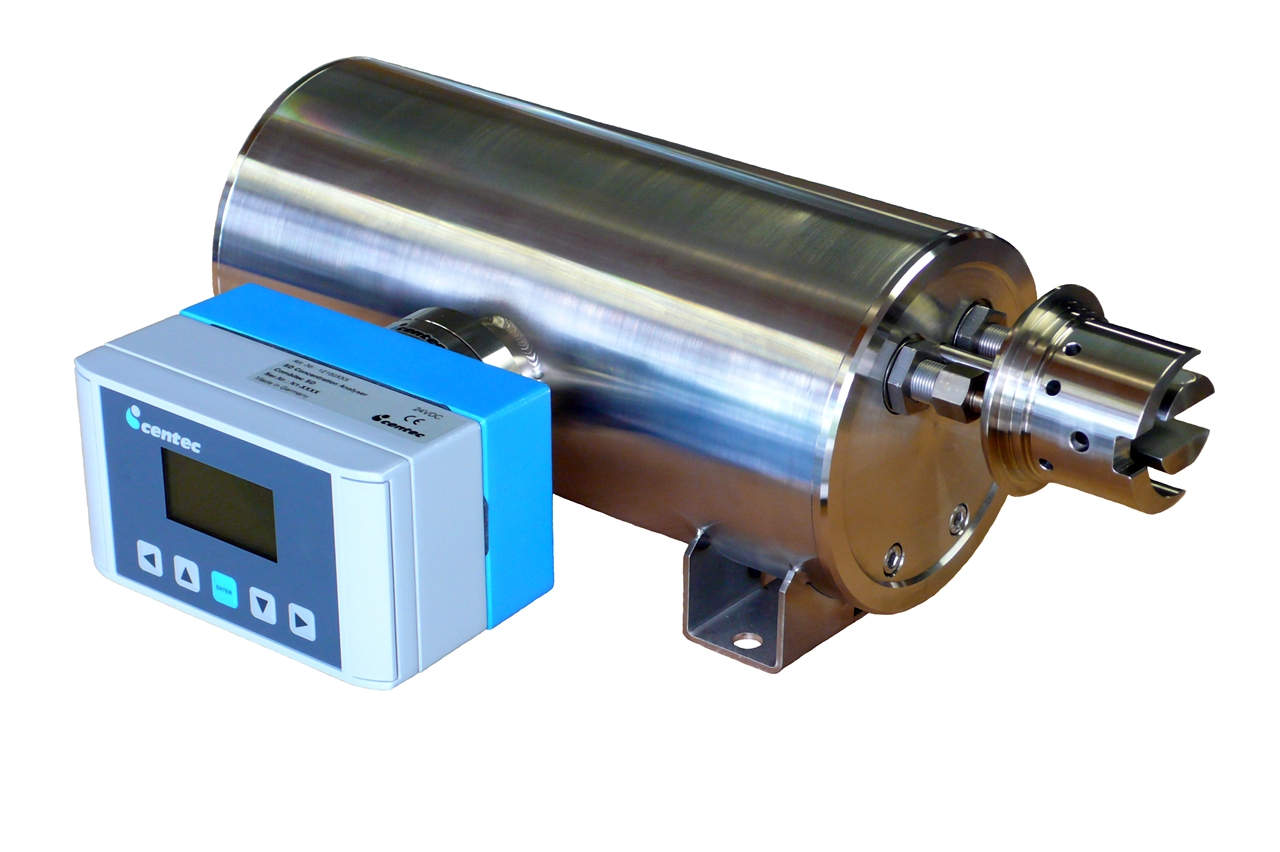

The Centec vacuum deaeration system VeGaS is a modular skid using a vacuum vessel for the removal of oxygen and other gases from a wide range of liquid products such as soy milk or tomato ketchup. The presence of even low oxygen levels can increase microbial activity and adversely affect taste, colour and shelf life of beverages and food products. Through special dispersion nozzles the liquid is sprayed into a continuously evacuated vessel. Due to the distribution of the fine liquid droplets, the transfer surface area between the liquid and the vacuum is maximized. The large partial pressure difference of O2 forces the oxygen out of the liquid into the vacuum. This fundamental scientific principle is described by “Henry’s Law”. Once the oxygen has been removed, it transfers out of the vessel through the vacuum line. The deaerated product collects at the bottom of the tank from where it is discharged for further processing. Vacuum deaeration can be assisted by a strip gas like nitrogen or carbon dioxide. O2 content monitoring with highly accurate OXYTRANS optical sensing technology developed and manufactured by Centec can be added, as can various other options.

Characteristic

· Application Specific and Energy Efficient extensive contact between liquid and vacuum subsequent disinfection of liquid product possible

· Modular Design with Standard PLC skid mounted for easy installation and start-up sturdy execution and largely maintenance-free

· Hygienic Execution and Full CIP Capability

· Outstanding Price-Performance-Ratio

Technical Data

Capacity 50 - 1.500 hl/h

Residual Oxygen Depending on product

Pressure of Operation 0 - 8 bar

Temperature of Operation 2 - 85 °C

Temperature of CIP Max. 85 °C

Material 1.4301/1.4404 AISI 304/316L

PLC SIMATIC S7

Options In-line O2/CO2measurement pasteurization additive

dosing/blending carbonation

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system.

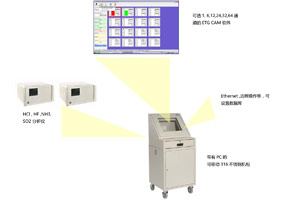

Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system. DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs

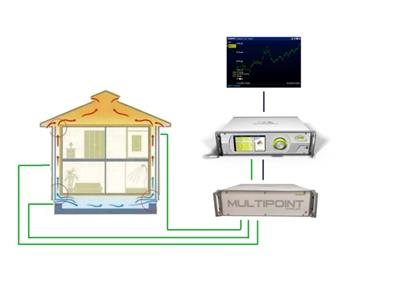

DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency.

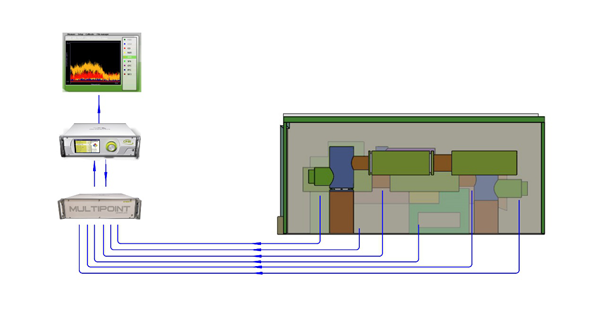

Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency. SF6 is widely used in GIS as a good insulation and interruption gas.

SF6 is widely used in GIS as a good insulation and interruption gas.