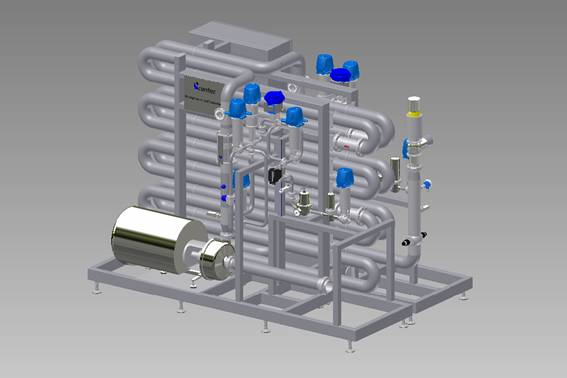

Nitrogenator

Principle

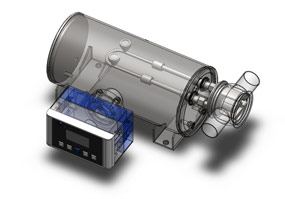

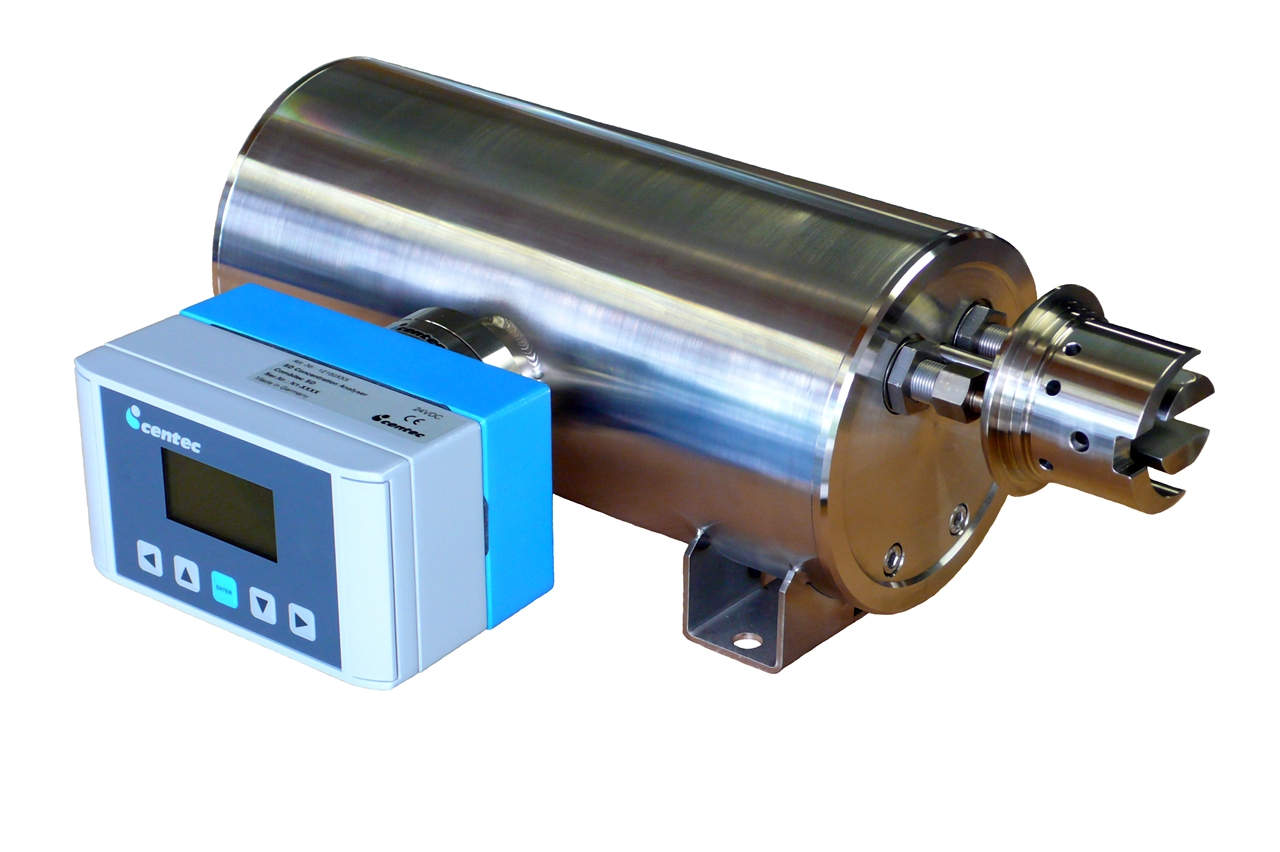

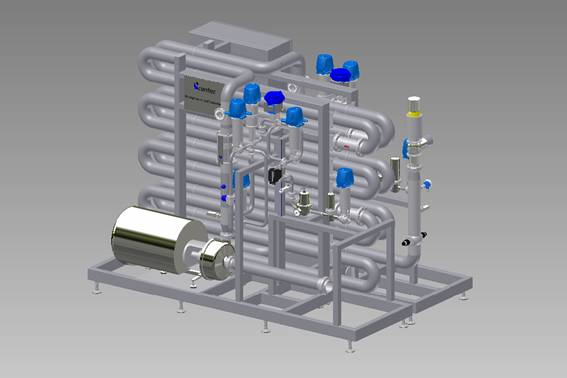

The Centec Nitrogenator is a modular skid which uses either one or several specifically designed Vortex injectors, or alternatively highly effective membrane contactors to reach exactly the required value of dissolved N2 in the beverage. The Vortex nozzles inject the gas as fine bubbles into the liquid stream. They ensure that the N2 dissolves perfectly and absolutely homogeneously in a very short time. Each contactor contains thousands of microporous hydrophobic hollow fibre membranes. Their large internal surface maximizes the contact area between liquid and gas. While N2 is applied on the inside of the hollow fibres, the beverage flows in counter current on the outside. With a high partial pressure difference between the liquid and N2 gas, the N2 permeates through the membranes into the beverage. This fundamental scientific principle is described by “Henry’s Law”. At the outlet of the system the N2 content is permanently measured with a highly reliable sensor. Based on this accurate in-line measurement, the N2 flow is instantly and fully automatically adjusted. The modular design of the process units allows for easy expansion, e.g. for blending or additional carbonation.

Characteristic

· Application Specific and Energy Efficient specifically designed Vortex-nozzle for N2 injection membrane contractors for increase or decrease of N2 blending or additional carbonation on demand

· Modular Design with Standard PLC skid mounted for easy installation and start-up

· Hygienic Execution and Full CIP Capability

· Outstanding Price-Performance-Ratio

Technical Data

Capacity 10 - 1.500 hl/h

Range of N2 0 - 100 ppm

Pressure of Operation 1 - 10 bar (Vortex injector) 0 - 6 bar (hollow fibre membranes)

Temperature of Operation 2 - 20 °C

Temperature of CIP Up to 85 °C

Material 1.4301/1.4404 AISI 304/316L

PLC SIMATIC S7

Options In-line measurement of O2/CO2/sugar/alcohol/...

carbonation blending

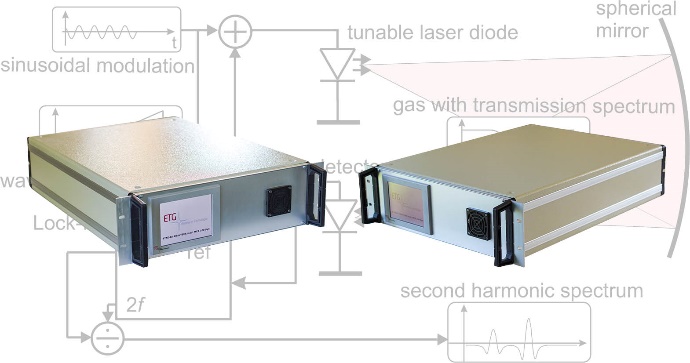

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied

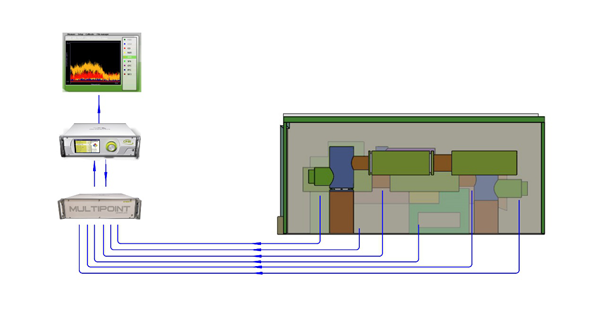

Based on infrared photoacoustic spectroscopy technology, DKG-ONE Photoacoustic Gas Analyzer combines the unique light source and detector which is a patented enhanced cantilever beam optical microphone with ultra-high sensitivity. It can be widely applied Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system.

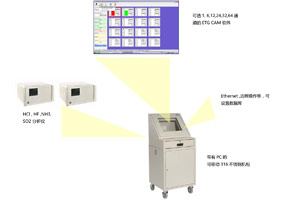

Transformer online monitoring and fault diagnosis technology is of great significance to improve the safety and stability of the power system. DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs

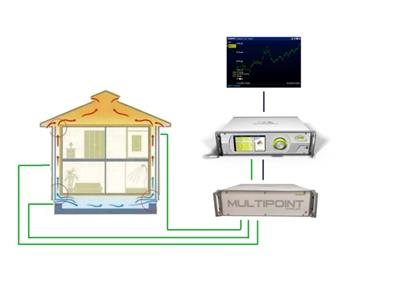

DK-BSC 3001 series battery spontaneous combustion monitoring system from Duke Technology integrates ultraviolet absorption spectrum, infrared photoacoustic spectrum, cavity enhanced absorption spectrum, Fourier infrared spectrum, tunable semiconductor abs Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency.

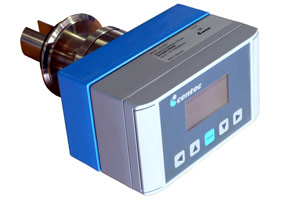

Ventilation system is to monitor the concentration change of tracer gas to calculate the ventilation efficiency. SF6 is widely used in GIS as a good insulation and interruption gas.

SF6 is widely used in GIS as a good insulation and interruption gas.